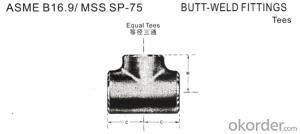

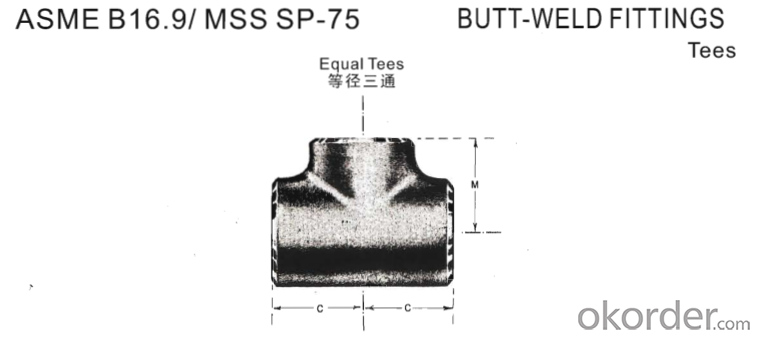

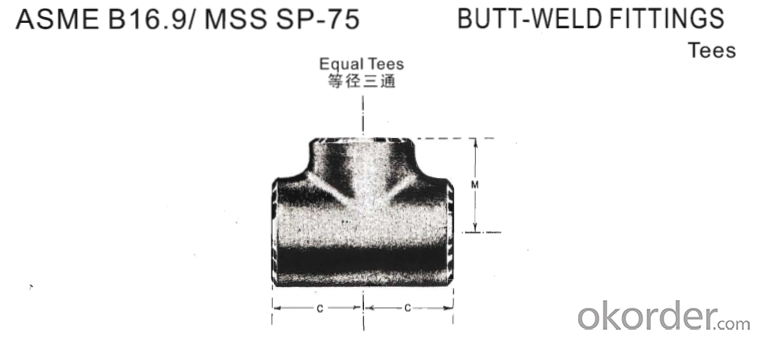

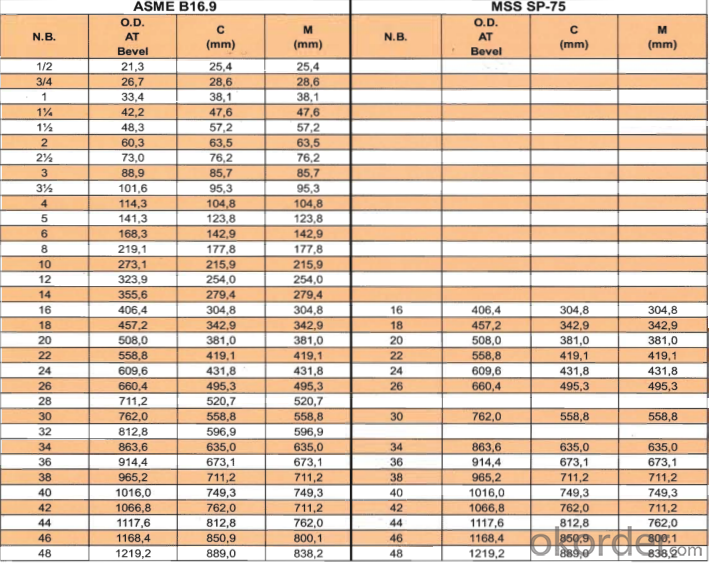

Steel Pipe Fittings Butt-Welding Equal Tees ASME B16.9/MSS SP-75

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features standards and products of our butt welding fittings:

Features of butt welding fittings:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of butt welding fittings:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process:

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Equal Tees:

Packing of butt welding fittings:

FAQ of butt-welding fittings:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q: Should I spend more on these lenses that reduce glare from headlights and fight reflections that cause eye strain and fatigue.The lenses will have less glare making them look invisible. Should I spend the extra money or will ordinary lenses do just fine

- NoIt is usually recomended you don't use a sealer on flare fittings.Can make a mess

- Q: Land lord now. We have nasty old singe pane windows. Can we request to replace them with double pane windows and would it resolve the mold issue?

- If they aren't welded, they don't count. If any are threaded and will be seal-welded later, they do count. If they have weld-neck flanges they do count. If there is no weld, why would they be counted?

- Q: I'm looking for a good bait casting rod. I was thinking about either the Berkley Amp or the Berkley Lighting rod shock. If you want to introduce me into new rods they have to be in a price range of $20-$50. Also if you find one it has to be at Cabela's or Bass Pro Shops. Thanks.

- if anything you want it quiete, why loud. you must have a bad neighbor.

- Q: the lightning theif? is it any good? whats it about??

- call a wholesale house that sells fittings and pipe they usually have pamphlets that have these dimensions Grinnell has one or a pipefitter handbook

- Q: I need to talk about it in my physics class

- Are you familiar with any type of soldering? There is low temp, and high temp, depending on the application, and the type of solder that you use. The most important thing to remember, is to thoroughly clean the inside of the fittings, and the end of the pipe. If you cut a pipe, make sure that you ream the inside, to restore the inner diameter of the pipe to its full bore dimension, otherwise, water will eat the pipes, from the inside, and you will have a premature breakdown in your piping system. A non acid, water soluble flux is required, again, so your pipes won't deteriorate from the inside. Low temp soldering can use a propane torch, but high temp, requires a hotter flame, to melt the solder. Practice on some pipes, before soldering for real. Never leave your flame in one spot too long. Doing so will cause the flux to be burned at that spot, and no solder will take at that spot, thus, ensuring a leak. Move your flame around the whole joint, heating it up uniformly, and concentrate your flame towards the center of the fitting, as solder will travel towards the heat. Good luck!

- Q: I have this sniper it costed me 300 bucks ive had it for about a year and its fps is between 350-450 somewhere and i wanna know on a scale of 1-10 how good it is. We play hardcore airsoft and play in the wilderness with ghillie suits and we are playing pro so we can be firing up to 1000 feet away and tbh when i fire the sniper bullets go really fast starting out and they immedtialey drop in the middle of the air like a dive bomb anyways is 350-450 for a airsoft sniper good for hardocre long range playing in the wilderness?

- try wearing a powder instead of a liquid foundation. and carry oil absorbing sheets or plot powder, or just a powder compact with you to touch it up when youre out (:

- Q: they contain an alpha emitter such as americium-231. Complete the following nuclear equation for the decay of americium 241 ?241 Am gt; 4 He+ ?95 2

- The household product that can be used when stop leak is unavailable or won't work is ground black pepper.

- Q: Need info to purchase the lock

- T Always keep them updated and scan and remove them. Each program is able to find different ones the other can't, so it actually is helpful to have all 3.

- Q: What kind of tubing connections do you have?.

- According to the number and direction of the connection, there are straight through, right angle, three pass and other types. The connection with the body has threaded connection, flange connection and so on. In addition, there are some special purpose pipe couplings.

- Q: PE pipe joint and PPR joint can be with each other

- So these two materials can not only connect through the interconnected adapter, such as thread or flange.I hope I can help my friends,

Send your message to us

Steel Pipe Fittings Butt-Welding Equal Tees ASME B16.9/MSS SP-75

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords