Stainless Steel Sheets 2B BA finish 201 304 316 430

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Stainless Steel Sheets 2B BA finish 201 304 316 430

Product name | stainless steel sheet 2b ba finish 201 304 316 430 |

Specification | Thickness: Cold rolled: 0.3-3mm, Hot Rolled: 3-120mm Customized sizes are accepted |

Standard | ASME, ASTM, EN, BS, GB, DIN, JIS, etc |

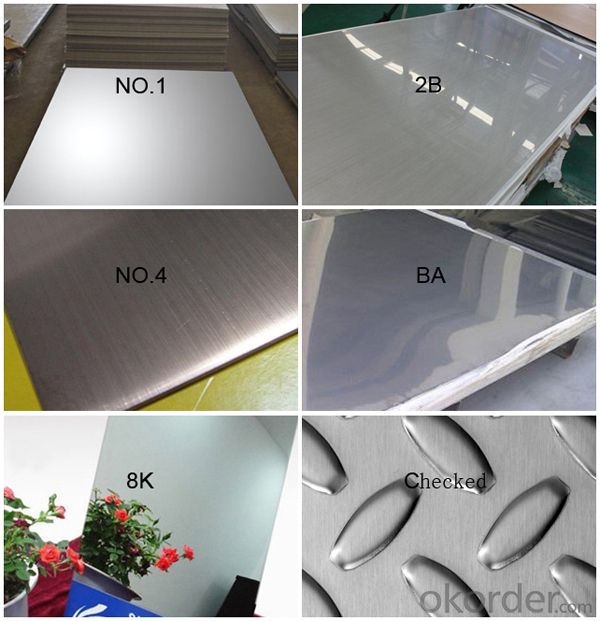

Finish | NO.1, NO.4, 2B, BA, HL, 8K, Mirror finish and so on |

Material | 201, 202, 304, 304L, 310S, 316, 316L, 410, 420, 430, 441, 800H, 904L |

Technical treatment | Cold Rolled, Hot Rolled |

Port of Loading | Tianjin, Shanghai, Ningbo, Guangzhou |

Terms of Delivery | FOB, CFR, CIF, CNF |

Terms of Payment | L/C, T/T (30% deposit) |

Packing | Standard export sea-worthy packing |

Delivery time | Within 7-15 days after receive 30% deposit or as your requirement |

Finished Products

Surface Finished | Characteristics | Application |

BA | Bright heat treatment after cold rolling. | Kitchen utensil, Kitchen ware, Architectural purpose. |

2B | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to more brighter and smooth surface. | General application medical instruments, Tableware. |

NO.1 | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface. | Chemical industry equipment, Industrial tanks. |

8K(mirror) | A mirror-like reflective surface by polishing with finer abrasives over 800 mesh. | Refletor, Mirror, Interior- Exterior decoration for building. |

Hair Line | Finished by continuous linear polishing. | Architecture industries, Escalators, Kitchen ware, Vehicles. |

Packaging & Shipping

Packaging:All products are packaged according to the Standard export packing.In order to prevent friction damage and water erosion and so on.

Shipping: Ocean transportation,land transportation or air transportation.

- Q: Can stainless steel sheets be used for power generation equipment?

- Yes, stainless steel sheets can be used for power generation equipment. Stainless steel is a versatile material that offers several beneficial properties for power generation applications. It has excellent corrosion resistance, which is crucial in environments where the equipment is exposed to water, steam, or other corrosive substances. Stainless steel also has high strength and durability, making it suitable for withstanding the high temperatures and pressures typically found in power generation systems. Additionally, stainless steel is a good conductor of electricity, making it suitable for electrical components and connections within the equipment. Therefore, stainless steel sheets are commonly used in the construction of power generation equipment such as turbines, boilers, heat exchangers, and exhaust systems.

- Q: Can stainless steel sheets be used for decorative staircases?

- Yes, stainless steel sheets can be used for decorative staircases. Stainless steel is a versatile material that offers a modern and sleek appearance, making it an ideal choice for creating decorative staircases. Its durability, resistance to corrosion, and ability to be shaped into various designs make stainless steel sheets a popular option for adding a stylish touch to staircases.

- Q: What is the maximum operating temperature for stainless steel sheets?

- The maximum operating temperature for stainless steel sheets varies depending on the grade of stainless steel. However, most commonly used grades can withstand temperatures up to 1500-1600°F (816-871°C).

- Q: What kind of welding rod is used for 310S stainless steel?

- A132 welding electrodes are used to weld important corrosion resistant, Ti stabilized 0Cr19Ni10Ti stainless steels.A137 is an Cr19Ni10Nb stainless steel electrode with an alkaline coating and a low carbon content containing Nb stabilizer. It is used for welding important corrosion resistant Ti stabilized stainless steel 0Cr19Ni11Ti.310S stainless steel is austenitic chromium nickel stainless steel, with good oxidation resistance, corrosion resistance, acid and alkali resistance, high temperature resistance. Mainly used in petroleum, electronics, chemical, pharmaceutical, textile, food, machinery, construction, nuclear power, aerospace, military and other industries.

- Q: What are the benefits of using diamond plate stainless steel sheets?

- Diamond plate stainless steel sheets offer several benefits. Firstly, they provide exceptional durability due to their rugged diamond pattern, making them resistant to wear and tear. This makes them ideal for heavy-duty applications and high-traffic areas. Secondly, the raised diamond pattern enhances slip resistance, ensuring a safer working environment. Additionally, diamond plate stainless steel sheets are corrosion-resistant, making them suitable for outdoor or wet environments. They are also easy to clean and maintain, making them a practical choice for a variety of industries. Overall, their strength, durability, slip resistance, and corrosion resistance make diamond plate stainless steel sheets a reliable and long-lasting option.

- Q: What are the different types of stainless steel sheet textures available?

- A variety of stainless steel sheet textures are available, each offering a distinct aesthetic and functional appeal. Some commonly used textures include: 1. Brushed: This texture is achieved by brushing the stainless steel surface with abrasive materials in one direction, resulting in a smooth, satin-like finish commonly found in kitchen appliances and decorative applications. 2. Mirror: As the name suggests, this texture creates a highly reflective and mirror-like surface. It is achieved by progressively polishing the stainless steel sheet with finer abrasives until a reflective finish is obtained. Mirror-textured stainless steel sheets are often used in architectural and decorative applications. 3. Embossed: This texture involves imprinting patterns or designs onto the stainless steel sheet using embossing rollers. The raised patterns add depth and visual interest to the surface, making it a popular choice for interior design applications such as wall cladding or elevator panels. 4. Perforated: This texture involves creating a pattern of holes or perforations on the stainless steel sheet. It allows for the passage of light, air, or liquids while adding a decorative element to the surface. Perforated stainless steel sheets are commonly used in architectural, interior design, and filtration applications. 5. Etched: This texture is achieved by chemically etching the stainless steel surface using acid or other corrosive substances. The etching process creates a pattern or design on the surface, resulting in a visually appealing, textured finish. Etched stainless steel sheets are often used in decorative applications such as signage, elevator doors, or wall panels. 6. Hammered: This texture involves using hammers or other tools to create a hammered or dimpled pattern on the stainless steel sheet. It adds a rustic, textured look to the surface and is commonly used in architectural and decorative applications. These examples showcase the range of stainless steel sheet textures available. Depending on desired aesthetics and functional requirements, there are numerous other textures and finishes that can be applied to stainless steel sheets to achieve different looks and effects.

- Q: What are the standard dimensions for stainless steel sheets?

- The standard dimensions for stainless steel sheets vary depending on the type and grade of stainless steel being used. However, there are some common sizes that are widely available in the market. For most stainless steel sheets, the standard width ranges from 36 inches to 48 inches, with a length varying between 72 inches to 120 inches. These dimensions are commonly used for stainless steel sheets used in various applications such as construction, automotive, and manufacturing. The thickness of stainless steel sheets can also vary, with common options ranging from 0.024 inches to 0.1875 inches. Thinner sheets are often used for decorative purposes or lightweight applications, while thicker sheets are utilized for heavy-duty applications that require higher strength and durability. It is important to note that these dimensions are general guidelines and can vary depending on the specific requirements of a project. Additionally, custom sizes can also be manufactured to meet the unique needs of a particular application. Overall, the standard dimensions for stainless steel sheets provide a range of options suitable for various industries and purposes, ensuring that there is flexibility in selecting the appropriate size for a specific project.

- Q: What are the different types of stainless steel sheet embossing patterns available?

- A variety of stainless steel sheet embossing patterns are available, offering different visual and tactile effects. Some of the most commonly used patterns are: 1. Diamond: This pattern consists of evenly spaced diamond-shaped indentations across the sheet's surface, creating an appealing textured appearance. 2. Linen: Resembling the texture of linen fabric, this pattern features parallel lines running in one direction and intersecting perpendicular lines, adding a subtle and sophisticated look to stainless steel sheets. 3. Stucco: The stucco pattern creates a raised, pebble-like texture on the sheet's surface, commonly used in architectural applications to enhance visual interest and provide a tactile feel. 4. Leather: This pattern imitates the texture of leather, with irregular lines and indentations, giving stainless steel sheets a unique and luxurious appearance. 5. Hammered: The hammered pattern showcases irregular indentations resembling hammer marks, contributing to a rustic and handcrafted look on stainless steel sheets. 6. Checkerboard: This pattern forms a grid of squares, with alternating squares raised or recessed, resulting in a classic and geometric design on stainless steel sheets. 7. Wave: The wave pattern showcases curved lines resembling ocean waves, adding a dynamic and flowing look to stainless steel sheets. These examples represent only a fraction of the available stainless steel sheet embossing patterns. Each pattern can be customized in terms of size, depth, and spacing to meet specific design preferences and application requirements.

- Q: Can stainless steel sheets be used for architectural canopies?

- Yes, stainless steel sheets can be used for architectural canopies. Stainless steel is a versatile material that offers several benefits in architectural applications, including canopies. Firstly, stainless steel is highly durable and resistant to corrosion, making it suitable for outdoor installations. This ensures that the canopy will withstand harsh weather conditions and maintain its appearance over time. Additionally, stainless steel has a sleek and modern aesthetic that can enhance the overall design of the canopy. It can be polished to a mirror-like finish or brushed to create a unique texture, providing architects with various options to achieve their desired look. Stainless steel sheets are also available in different thicknesses, allowing for customization based on the specific requirements of the canopy. This flexibility ensures that the material can support the weight of the structure and any additional elements, such as lighting or signage. Moreover, stainless steel is a sustainable choice for architectural canopies as it is fully recyclable. This aligns with the growing demand for environmentally-friendly construction materials and practices. In summary, stainless steel sheets are a suitable and popular choice for architectural canopies due to their durability, aesthetic appeal, flexibility, and sustainability.

- Q: Can stainless steel sheets be used for storage racks?

- Yes, stainless steel sheets can be used for storage racks. Stainless steel is a durable and corrosion-resistant material, making it ideal for storage racks that may be exposed to moisture or other harsh conditions. Stainless steel sheets can be fabricated into various shapes and sizes to suit different storage needs, and they can support heavy loads without warping or bending. Additionally, stainless steel is easy to clean and maintain, ensuring a hygienic storage environment. Overall, stainless steel sheets are a reliable choice for storage racks in industries such as food and beverage, pharmaceuticals, and warehouses.

Send your message to us

Stainless Steel Sheets 2B BA finish 201 304 316 430

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords