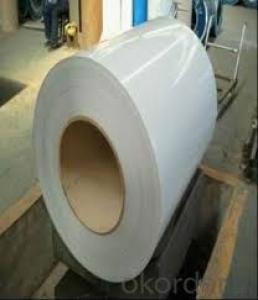

STAINLESS STEEL COILS Mill Edge. No connection point in each coil.

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

STAINLESS STEEL COILS

Packaging & Delivery

Packaging Detail: seaworthy export package

Delivery Detail: on request

Specifications

1. more than 10 years’ experience on this field

2. advanced equipments

3. competitive price

4. soonest delivery

Product Description :

Commodity

STAINLESS STEEL COILS

Technical Standard: Steel Grade & Standard:J1

Surface Treatment:NO.1

Hot rolled Annealed and Pickled(HRAP)

Grade: J1 , Prime quality

Mill Edge. No connection point in each coil. Component: Ni:1% , Cu: 0.65-0.9%, Cr: 13%, Mn: 10–12%, C: 0.09-0.12%

Package: Properly packed for ocean freight exportation in 20''container

Application:: home appliances, constructions, building, machineries

Our Advantages :

1. Expertise:

More than 10 years of manufacture: we know how to properly handle every step of production.

2. Competitive price:

We can offer competitive prices to our customers.

3. Accuracy:

We have excellent technicians and leaders, which can ensure our products are exactly what you want.

4. Materials:

All steel coils are made of high-quality raw materials.

5. Certificate:

Our products are certified by ISO9001.

6. Productivity:

We have large-scales of production lines,, which can guarantee all your orders will be finished in earliest time.

The furnace heating style: improved Sendzimir heating technology

Hourly output: max.76.3t/h

Process after coating: tension leveling, Passivation or oiling

Our Service

Our quality

Test Equipments of Prepainted Galvanized Steel Coil : Salt-spray tester; Atomic absorption spectrophotometer; Rockwell typer hardness tester; Tensile test machine; Metrohm titration; Laboratory Bend test machine.

Our packing

Properly packed for ocean freight exportation in 20''container, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference.

R&D department

R&D department concentrates on researching and developing reliable products with best quality. The quality department test and control every process of production to guarantee the best quality of product

- Q: Can steel coils be used in the production of medical equipment?

- Yes, steel coils can be used in the production of medical equipment. Steel is a strong and durable material that can provide structural support and stability to various medical devices and equipment. It is commonly used in the manufacturing of instruments, surgical tools, and machinery used in medical settings.

- Q: What are the dimensions of steel coils used in the storage tank industry?

- The dimensions of steel coils used in the storage tank industry can vary depending on the specific requirements of the tank being manufactured. However, in general, steel coils used for storage tanks are typically available in various sizes and thicknesses. The width of steel coils can range from around 600 millimeters to 2,400 millimeters, while the length can vary from several meters to tens of meters. The thickness of the coils can also vary, typically ranging from 1.5 millimeters to 10 millimeters or more. These dimensions are determined by factors such as the size and capacity of the storage tank, the material being stored, and the structural requirements of the tank. The specific dimensions for a given storage tank project would be determined by the tank manufacturer or designer, in accordance with industry standards and specific project specifications.

- Q: many sword sellers sell swords made of 440 and stainless, i know those are both totally **** for real swords. so are 1045, 1060, or 1095 good grades of steel for a sword?

- Carbon Steel is the most common, while most live-steel(designed for use) ready sword utilize on of the spring steels you mentioned. Hybrid steel like those used in the Slayer series seem neigh-indestructible. The steel should be strong enough to not notch on a strike, but flexible enough to flex when you bend it, lest it shatter on a hard blow.

- Q: Can steel coils be used in the manufacturing of machinery and equipment?

- Yes, steel coils can be used in the manufacturing of machinery and equipment. Steel coils are versatile components that provide strength, durability, and stability to various industrial applications. They can be shaped, cut, and formed into different parts and components necessary for the machinery and equipment manufacturing process. Steel coils are commonly used in the production of gears, shafts, frames, brackets, and other structural elements. Additionally, they can be processed further to create specialized components such as springs or fasteners. The use of steel coils in machinery and equipment manufacturing ensures that the end products are of high quality, capable of withstanding heavy loads, and have a long lifespan.

- Q: What are the common applications of coated steel coils?

- The excellent properties and versatility of coated steel coils make them suitable for a wide range of applications in various industries. Some common uses of coated steel coils include: 1. Construction industry extensively employs coated steel coils for roofing, cladding, and wall panels. The coating ensures long-lasting structures by providing superior corrosion resistance, durability, and weatherability. 2. In the automotive industry, coated steel coils are widely used for manufacturing body panels, bumpers, and chassis parts. The coatings enhance aesthetics, protect against corrosion, and improve paint adhesion for a flawless finish. 3. Coated steel coils find utility in the production of household appliances like refrigerators, washing machines, and ovens. The coatings provide an attractive, smooth finish while protecting the steel from moisture and environmental factors. 4. Heating, Ventilation, and Air Conditioning (HVAC) systems commonly utilize coated steel coils for manufacturing ductwork, air handling units, and heat exchangers. The coatings ensure resistance against corrosion and improve system efficiency. 5. The furniture industry also makes use of coated steel coils for manufacturing cabinets, tables, and chairs. The coatings provide a decorative finish while protecting the steel from wear and tear. 6. Electrical equipment production, including switchboards, control panels, and enclosures, involves the use of coated steel coils. The coatings provide insulation and protection against electrical conductivity, ensuring durability. 7. In the packaging industry, coated steel coils are used for manufacturing cans, containers, and closures. The coatings act as a barrier against moisture and prevent contamination, ensuring the preservation and safety of packaged products. In conclusion, coated steel coils offer corrosion resistance, durability, aesthetics, and protective properties, making them suitable for various applications across industries. From construction to automotive, appliances to furniture, and even in electrical equipment and packaging, coated steel coils play a crucial role in delivering high-quality products and ensuring long-lasting performance.

- Q: How are steel coils used in the production of industrial valves?

- Steel coils are used in the production of industrial valves as they provide a high-strength and durable material for constructing the valve bodies, stems, and other components. The coils are typically shaped, cut, and formed into various valve parts, which are then assembled and welded together to create the final valve product.

- Q: Hey do you know what is Steel Arch Building and how it looks like exactly??

- Typically, okorder /

- Q: Can steel coils be cut?

- Yes, steel coils can be cut using various methods such as shearing, sawing, or laser cutting, depending on the thickness and type of steel.

- Q: Cold rolled steel coil steel, what is the difference?

- Hot rolling is made of slabs (mainly continuous billets) as raw materials. After heating, strips are made from roughing mills and finishing mills.

- Q: What is the process of uncoiling a steel coil?

- The process of uncoiling a steel coil involves using specialized equipment, such as a decoiler or uncoiler machine, that is designed to carefully unwind the tightly wound coil. The coil is typically mounted onto the machine's mandrel, which holds it securely in place. As the machine rotates, the coil starts to unwind, with the outer layers gradually releasing and straightening out. This process continues until the entire coil is uncoiled, resulting in a flat and straight steel sheet or strip ready for further processing or use in various applications.

Send your message to us

STAINLESS STEEL COILS Mill Edge. No connection point in each coil.

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords