Split Casing Double Suction Centrifugal Water Pump for Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

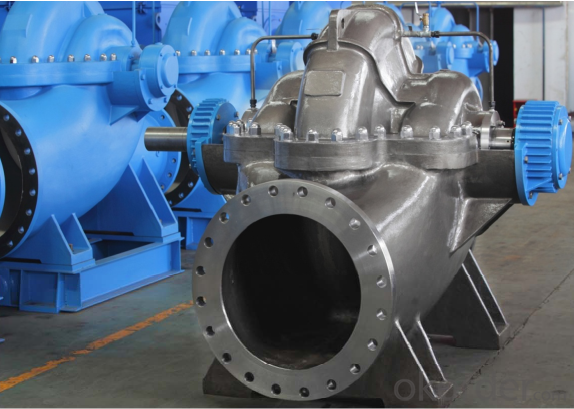

Split Casing Double Suction Centrifugal Water Pump for Irrigation

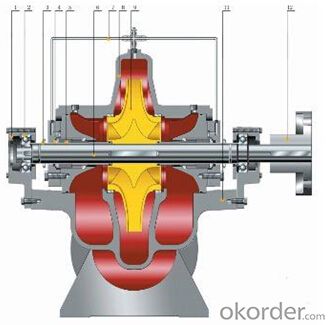

1.Split Casing Double Suction Centrifugal Water Pump for Irrigation Description

The Single Stage Double Suction Split Casing Centrifugal Pump is designed for Irrigation, The casting is axially split, which permits removal of the complete rotor whish moving either piping or motor. Pumps generating high heads have double volute to reduce radial forces. Replaceable wear ring protect the casting at the impeller running clearances. Flange drilled to ISO, DIN, BS or ANSI. The close double suction impeller gives practically zero axial forces. Each impeller is statically and dynamically balanced according to ISO 1940.The pumps have a reduced number of parts and extensive interchangeability, which leads to minimum levels of inventory for customers and faster parts delivery. Vertical installation is a standard option with the same upper and lower casing parts. It is mounted for a space-saving configuration or when apace is at a premium. Soft packing or mechanical seal, grease or oil lubricated bearing is optional. Oil lubrication is with constant level oiler.

2.Main Features of Split Casing Double Suction Centrifugal Water Pump for Irrigation

•Attractive design

•High efficiency, steady performance

•Big capacity, medium pressure

•High concentricity of components

3.Split Casing Double Suction Centrifugal Water Pump for IrrigationSpecification

Casing | Cast Iron, Ductile Cast Iron, Cast Steel, Stainless Steel or Duplex S.S |

Impeller | Cast Iron, Bronze, Duplex S.S, Stainless Steel |

Shaft | C-Steel, Cr-Steel, Stainless Steel |

Wearing Ring | Cast Iron, Brass, Stainless Steel |

Capacity/Q | Up to 25000m3/h, Up to 110000gpm |

Head/H | Up to 280m, Up to 800 feet |

Temperature/T | Up to 200degree |

Speed/n | 2900/1450/980/740/580 rpm 3500/1750/1180/890/710rpm |

4.Picture of Split Casing Double Suction Centrifugal Water Pump for Irrigation

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference.

- Q: I think the water pump is going out in my truck can I still drive it short distance if I put water in it first?

- Depends on how bad the water pump is. Is it getting really hot already? Is it leaking water really bad? Answer yes to either one of these and you would probably be best to get it towed to the shop. Most vehicles now have aluminum heads, and over-heating the engine can easily lead to a warped head. That is going to be a whole lot more expensive to fix than what it would cost for a tow. If it holds water and doesn't get too hot, give it a try if it's a short distance, just keep an eye on the temperature gauge. Pull over before it gets into the red zone.

- Q: Pump pumping small is what happened?

- You are lifting pump or submersible pump ah? Lift pump before pumping water pump, first open the pump and then open the outlet valve, and if there is no pressure, it is time to leave, the sealing performance is not good, check where leakage, and perhaps your pump is broken

- Q: Okay, I have a 1982 Suzuki Dt8 that someone gave me. But it will not pump water well, when you reve it it will have a little watter shoot out the water outlit, but heres the thing. if you take the cover off be the shift linkage and run the engin it will pump water through just fine

- I've passed on answering your question a couple times, mainly because I'm not sure exactly what you are asking. So let me ask. In the water does the engine overheat? I'm not sure that what you are looking at isn't the relief hole and not the water discharge, which should be under water. How are you supplying water to your engine? Are you running in a barrel? The water pump should be replaced every 2-3 years, so unless you are going to do it yourself, take it to a shop and explain what you are observing. Taking the cowling off will have no effect on the water pump, so I'm guessing you are looking at the wrong place. P.S. This was a common error with Evinrude small motors back in the 70's and 80's, motors similar to yours. The exhaust fin was just behind the propeller. not higher up the leg

- Q: ive been doing repair work on an old 86 jeep cherokee and when i let it idle there is a water leak, me and my dad came to the conclusion there was something wrong with the water pump. i cant find the manual and i dont even know what im looking for, so where would i find the water pump and how would i go about replacing it?

- For 2.5L 4.0L Engines Some vehicles use a serpentine drive belt and have a reverse rotating water pump coupled with a viscous fan drive assembly. The components are identified by the words REVERSE stamped on the cover of the viscous drive and on the inner side of the fan. The word REV is also cast into the body of the water pump. 1. Disconnect the negative battery cable. 2. Drain the cooling system. 3. Disconnect the hoses at the pump. 4. Remove the drive belts. 5. Remove the power steering pump bracket. 6. Remove the fan and shroud. 7. If equipped, remove the idler pulley to gain clearance for pump removal. 8. Unbolt and remove the pump. To install: 9. Clean the mating surfaces thoroughly. 10. Using a new gasket, install the pump and tighten the bolts to 13 ft. lbs. (18 Nm). 11. If removed, install the idler pulley. 12. Reconnect the hoses at the pump and install accessory drive belt. 13. Install the power steering pump bracket. Install the fan and shroud. 14. Adjust the belt tension and fill the cooling system to the correct level. 15. Operate the engine with the heater control valve in the HEAT position until the thermostat opens to purge air from the system. Check coolant level and fill as required.

- Q: A total of three units, usually starting two units. After jumping the gate, it was like this. I haven't paid attention before. Is it a turn around?

- Only trip is not to the frequency converter settings or phase sequence change, if not moved the settings and wiring, most of the reason is the original reversal, you also know that inverter turnover also has water.Check analog positive and negative polarity, inverter settings, and if there is no problem, change the phase sequence.

- Q: I will be replacing my water pump tomorrow and my question is can I use copper spay gasket to spray on the water pump gasket?it this stuff good?99 ford explorer 4.0 ohv with 144k,mileshere is a pictures of the product.

- Sure, why not? Usually, the metal area when most water pumps are bolted too are cleaned with a scraper of some kind and old gasket matter is removed. That surface should be cleaned, flat, and free of irregularity. Most mechanics, if they use any kind of stickum - like contact cement from a tube, or the costlier, but not-needed specialty sealers, is applied to the pump surface so the gasket stays put and not move when installing the bolts. The glue does not do any actual sealing, just the fiber gasket will. None needs to be applied to the engine side that you scraped clean. Make sense to you? It's probably a good idea to service the cooling system with a non-caustic flush cleaner before hand -since all the coolant will come out during the change. Then add a additive that neutralizes acids with the new anti-freeze.

- Q: Mercedes 2000 ml 320. I changed radiator and water pump now car only runs half as worm than it used to. So now heat blows cold to little warm depending on how cold out side

- flush out the heater core and change the thermostat !

- Q: I am trying to replace a water pump on my ranger and i have all the bolts out. It seems to be stuck i think it is because of the oring around the outside of the pump andy ideas of how to free it?

- if all the bolts are out then take a rubber hammer and tap on it. it,s probably stuck on the gasket.

- Q: Is a 3000 watt generator sufficient to power a 3/4 horsepower water pump?My house has a 3/4 horsepower pump that it uses to pump water from the well to the house. I want to purchase a generator that will be sufficient to power this pump in a power outage. Is 3000 Watts sufficient?

- Danny and GTB give a good answer, I just add some: As a rule of thumb, 1 horsepower (HP or hp) is equal to 750 watts, and a motorized electric equipment at start up will suck electricity power about twice as much as its specification. Is you pump equipped with a three phase or a single phase electric motor? You have to suit it with the generator. As for the generator, if possible you choose a generator with big flywheel, with slower RPM -rotations per minutes- than a generator with high RPM, because a water pump will frequently on and off according to the usage. This could cause the generator to wave down and up accordingly. Or a generator equipped with an electronic governor that will react fast enough to the frequent on and off load of the water pump. Hope the best and God bless you and good luck day by day!!

- Q: Hey I need to pump water from a river and use be able to use it through a hose and also make the hose have pressure. I was thinking pump the water into a barrel and into a hose or something from there? Anyone know anything about if this would work? What would I need? thanks

- buy a submersible water pump. they are the best and longest runing with high pressure. also they are portable and u can take out any time. they are applicable in sea , rivers, very deep pumping etc. but remember to wrap it with a light and silky cloth to prevent the sand going in to it before use in sea and rivers. u dont need a barrel or tank. As they re not heating,they can work continuously even for a years.u can operate from a distance, much pressure than any centrigugal pump. hope it heps. good luck.........

Send your message to us

Split Casing Double Suction Centrifugal Water Pump for Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords