Self-adhesive Waterproofing Membrane CMAX

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Self-adhesive Waterproofing Membrane:

Self Adhesive Bitumen Waterproof Membrane

Introduction of Self-adhesive Waterproofing Membrane:

SBS(Styrene Butadiene Styrene) /APP (Atactic Polypropylene) modified bitumen membrane is made by saturating the base in bitumen, or thermoplastic elastomer (such as SBS, APP, APAO, APO), reinforced with polyester or fiberglass, finishing the upward face with polythene membrane, fine sands or mineral slates (or grains) or etc.

Specification of Self-adhesive Waterproofing Membrane:

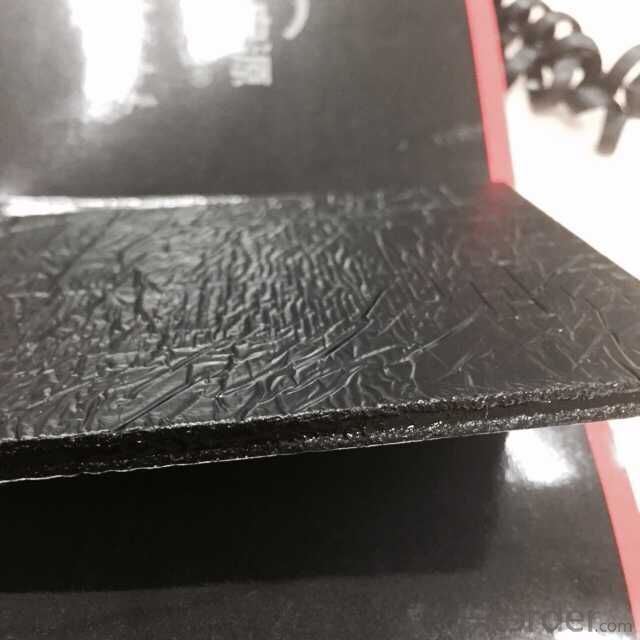

Thickness | 3mm, 4mm, 5mm |

Width | 1m |

length | 7.5m, 10m, 15m, or on demand |

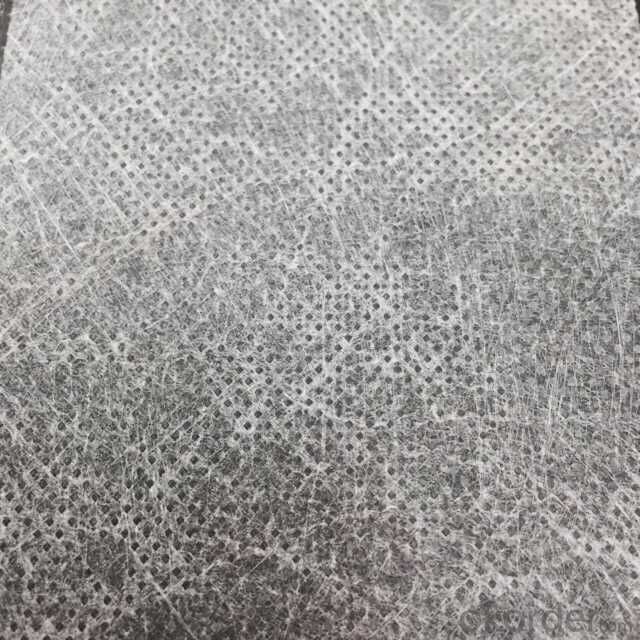

Base | Polyester or Fiberglass felt |

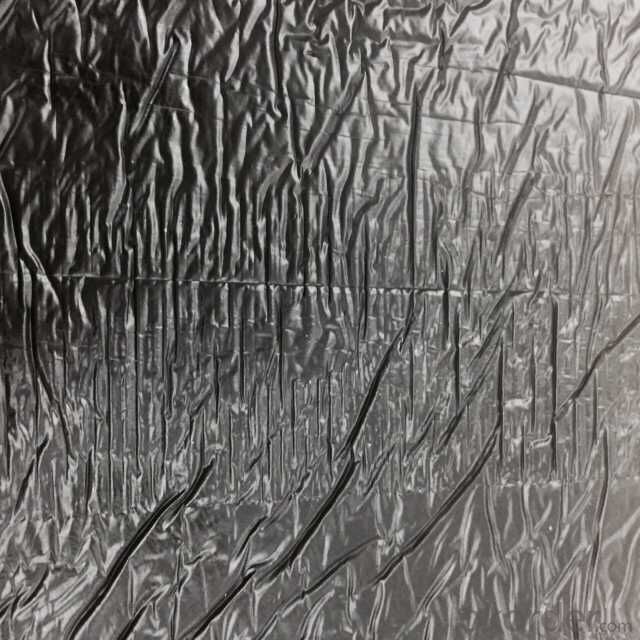

Surface | PE film, Aluminum foil, Yellow sand, Shale gravel(Schist), colored sand |

Type | could self-adhesive |

Notice | SBS modified bitumen membrane is specially applied in the cold district, APP modified bitumen membrane is more suitable for hot district with high temperature. could be self-adhesive modified bitumen membrane |

Applications:

-Roof and underground in industrial and civil buildings;

-Bridge, subway, tunnel, swimming pool, etc.

-Waste landfill, sewage plant, irrigation system, etc.

-Self-adhesive Modified Bitumen Waterproof Membrane

-Easy applying and economic on the cost saving

Advantage:

-Non-solidified, excellent elastic deformation,thus have good noise reducing;

-Easy applying and economic on the cost saving.

-Good performance on waterproof and economic sound damping.

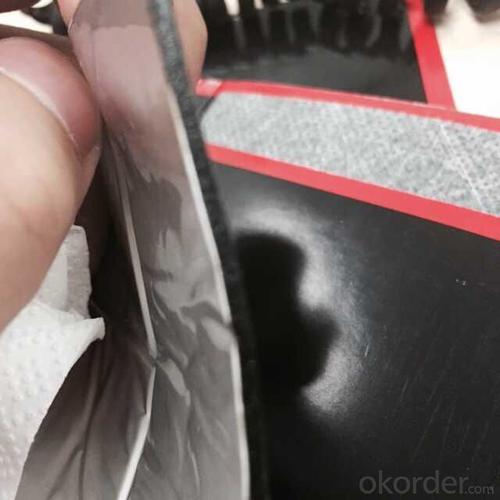

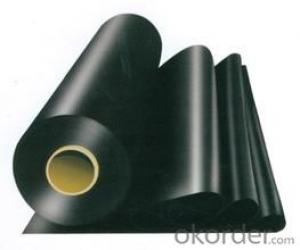

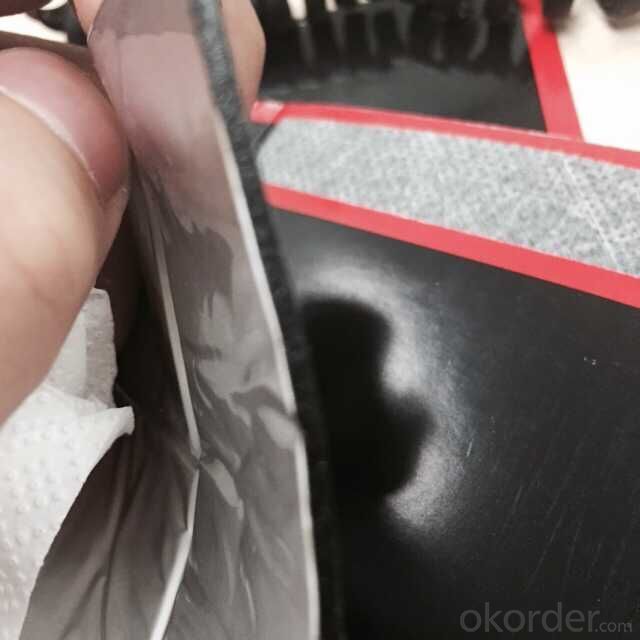

Picture:

Storage of Self-adhesive Waterproofing Membrane:

Shelf life is 12 months. Store in a cool and dry place with original packing.

Breathable Waterproof Roof Underlay membrane (PP-PP,S-PP,S-S)

Permeable membrane is polymer modified asphalt based, with surface of high strength polypropylene fiber. Back side coated with self adhesive glue or antiskid sand. Made by special process. With excellent waterproof performance and breathable properties.\

Description | Specification | Width | Length | Thickness | |

Roof underlay | 500g/m2PP—PP | 1000mm | 30m | 0.8mm | |

600g/m2S—PP | 1000mm | 25m | 1.0mm | ||

1500g/m2S—S | 1000mm | 20m | 1.3mm | ||

Roof underlay with adhesive band | 500g/m2PP—PP | 1000mm | 30m | 0.8mm | |

600g/m2S—PP | 1000mm | 25m | 1.0mm | ||

1500g/m2S—S | 1000mm | 20m | 1.3mm | ||

It is used as the underlayment of cement tile, painted pottery watts and asphalt shingle. Also suitable for all kinds of architectural roofing, walls, underground waterproof and damp proof project.

Features of Self-adhesive Waterproofing Membrane:

It has good waterproofing and ageing-resistance function,not flowing at highest temperature and no crack at lowest temperature;

Easy application,no pollution,and long service life etc.

Usage of Self-adhesive Waterproofing Membrane:

It is widely used for industry and civil building --- the waterproof and dampproof of the roofs,basements,toilets etc;and the waterproofing of bridges,parking area,tunnels,reserviors etc.

It is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions.

Requirements for surroundings of Self-adhesive Waterproofing Membrane

-The base should be dry and clean. Do not work in the rainy or snowy day.

-Do not work under heavy wind(above 5 grade)

-Unsuitable for construction below 0°C

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used for underground utility vaults?

- Indeed, underground utility vaults can benefit from the utilization of waterproofing membranes. These specialized membranes are specifically engineered to serve as a shield against water infiltration, and they find extensive application in a wide range of construction projects, such as underground structures like utility vaults. By employing waterproofing membranes, the undesirable consequences of water damage, corrosion, and leakage can be effectively averted in underground vaults, thereby safeguarding the utilities and equipment housed within and ensuring their durability and longevity.

- Q: Can a waterproofing membrane be used in permanent or long-term structures?

- Yes, a waterproofing membrane can be used in permanent or long-term structures. Waterproofing membranes are designed to provide durable and long-lasting protection against water intrusion. They are commonly used in various construction applications such as basements, roofs, foundations, and underground structures to prevent water damage and leakage. These membranes are engineered to withstand the test of time and can effectively extend the lifespan of a structure by ensuring its integrity and preventing moisture-related issues.

- Q: How does a waterproofing membrane handle movement of a building due to settling or seismic activity?

- The primary purpose of a waterproofing membrane is to adapt to a building's movements resulting from settling or seismic activity. By offering a pliable and resilient barrier, it effectively expands and contracts alongside the building, effectively preventing water infiltration. When a building settles or experiences seismic activity, it may undergo significant structural shifts. These shifts can result in cracks, displacements, or alterations in the building's foundation, walls, or floors. In the absence of adequate waterproofing, water can infiltrate through these cracks or gaps, leading to water damage, mold growth, and structural degradation. To address this issue, waterproofing membranes are typically fabricated using materials that possess exceptional elongation and recovery properties. Elongation pertains to the membrane's capacity to stretch without tearing, while recovery refers to its ability to return to its original shape after being stretched. This flexibility permits the membrane to synchronize its movements with the building, rather than resisting or fracturing under stress. Furthermore, waterproofing membranes are installed in a manner that accommodates horizontal and vertical movement. They are often applied in multiple layers, with overlapping seams, to establish an uninterrupted barrier. This layered approach enables the membrane to adapt and align with any potential shifts or settlements in the building. In regions prone to seismic activity, additional measures may be implemented to fortify the waterproofing system. These measures can involve using specialized membranes with heightened elongation and recovery properties or incorporating reinforcement elements such as fabric or mesh to enhance the membrane's ability to handle movement. In conclusion, a waterproofing membrane is specifically engineered to manage a building's movement caused by settling or seismic activity. Its adaptability, elongation, recovery properties, and appropriate installation techniques enable it to accommodate the building's movements while sustaining a watertight barrier.

- Q: Can a waterproofing membrane be used for plaza decks?

- Yes, a waterproofing membrane can be used for plaza decks. Waterproofing membranes are commonly used in construction to prevent water infiltration and protect the underlying structure. Plaza decks are outdoor spaces that require protection against water damage, making waterproofing membranes an ideal solution to ensure the longevity and durability of the deck.

- Q: What is the lifespan of a waterproofing membrane in extreme weather conditions?

- The lifespan of a waterproofing membrane in extreme weather conditions can vary depending on various factors such as the quality of the membrane, the intensity and duration of the weather conditions, and the maintenance and care provided to the membrane. In general, high-quality waterproofing membranes designed for extreme weather conditions can have a lifespan of 20-30 years or more. These membranes are typically made from durable materials such as modified bitumen, PVC, EPDM, or TPO, which are specifically engineered to withstand harsh weather elements. However, it is important to note that extreme weather conditions, such as heavy rain, intense sunlight, freezing temperatures, or strong winds, can accelerate the wear and tear of the membrane. For example, prolonged exposure to UV radiation can cause the membrane to degrade and lose its effectiveness over time. Regular maintenance and inspections are crucial to prolonging the lifespan of the waterproofing membrane in extreme weather conditions. By promptly addressing any signs of damage, such as cracks, tears, or leaks, and conducting regular cleaning and resealing, the membrane can be better protected against the harsh effects of extreme weather. Furthermore, proper installation techniques and following manufacturer's guidelines are essential to ensure the longevity of the waterproofing membrane. Hiring experienced professionals who are familiar with installing membranes in extreme weather conditions can greatly contribute to the durability and lifespan of the membrane. Ultimately, while a high-quality waterproofing membrane can withstand extreme weather conditions for several decades, it is important to monitor its condition regularly, provide proper care and maintenance, and promptly address any issues that arise to maximize its lifespan.

- Q: Can waterproofing membranes be used on bridge decks?

- Bridge decks can benefit greatly from the application of waterproofing membranes. Due to the constant exposure to harsh weather conditions like rain, snow, and freeze-thaw cycles, the concrete and steel reinforcement of bridge decks can deteriorate. Waterproofing membranes are specifically designed to counter water infiltration and safeguard the bridge deck against damage caused by moisture. Typically composed of flexible materials like bitumen, PVC, or EPDM rubber, these membranes are directly applied to the surface of the bridge deck. Acting as a barrier, they prevent water from seeping into the concrete and causing corrosion of the reinforcement. They also help minimize crack formation and extend the lifespan of the bridge deck. Furthermore, the effectiveness and durability of waterproofing membranes can be enhanced by combining them with other protective coatings or systems. All in all, the utilization of waterproofing membranes on bridge decks is a widely employed and successful approach to ensure the long-term integrity and functionality of the structure.

- Q: SBS modified asphalt waterproofing membrane and synthetic polymer membrane the same, not the same, what is the difference?

- SBS modified asphalt waterproofing membrane is a kind of high-polymer modified asphalt waterproofing membrane, high polymer modified asphalt waterproofing membrane is synthetic polymer modified asphalt coating layer,

- Q: Can a waterproofing membrane be used for swimming pools?

- Certainly, swimming pools can utilize a waterproofing membrane. These membranes are specifically designed to hinder water infiltration and can be applied to various surfaces, including concrete, to establish a completely impermeable seal. This is especially crucial for swimming pools, as they are continuously exposed to water and necessitate a dependable waterproofing system to avert leaks and water-related harm. The waterproofing membrane acts as a safeguarding barrier, guaranteeing that the pool retains its watertightness and preventing any water from seeping into the nearby structures. Furthermore, waterproofing membranes also offer resistance against chemicals, UV rays, and other environmental factors, effectively fortifying the swimming pool's durability and longevity.

- Q: Can a waterproofing membrane be used for soundproofing purposes?

- Yes, a waterproofing membrane can be used for soundproofing purposes to some extent. While its primary function is to prevent water penetration, it can also help to reduce sound transmission. Waterproofing membranes are typically made of materials that have good acoustic properties, such as rubber or a combination of rubber and asphalt. These materials can absorb and dampen sound waves, thereby reducing the amount of noise that passes through a wall or floor. However, it is important to note that the soundproofing effectiveness of a waterproofing membrane may not be as high as that of specialized soundproofing materials like acoustic panels or insulation. Therefore, if soundproofing is the main goal, it is recommended to consider using dedicated soundproofing solutions in addition to or instead of a waterproofing membrane.

- Q: Can a waterproofing membrane reduce noise transmission?

- Yes, a waterproofing membrane can reduce noise transmission.

Send your message to us

Self-adhesive Waterproofing Membrane CMAX

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords