Self-adhesive Bitumen Waterproof Membrane CMAX

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

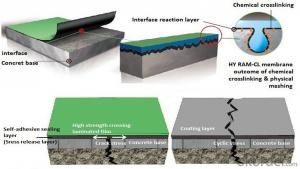

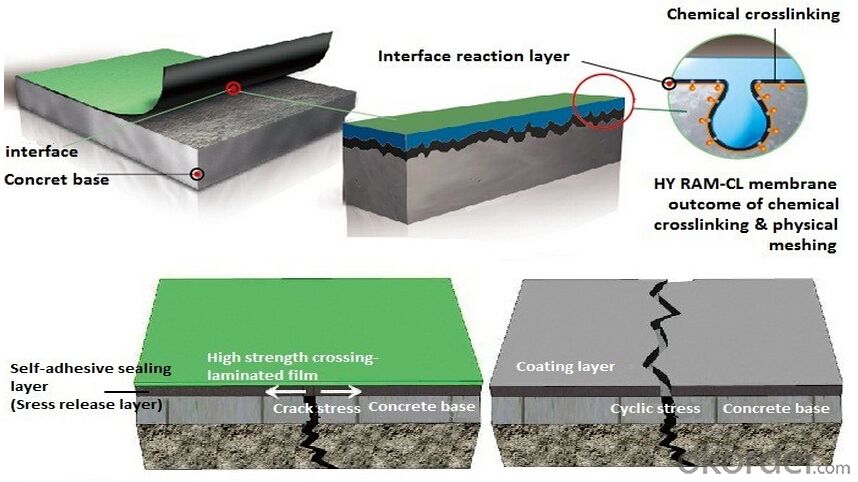

Introduction Self-adhesive Bitumen Waterproof Membrane CMAX:

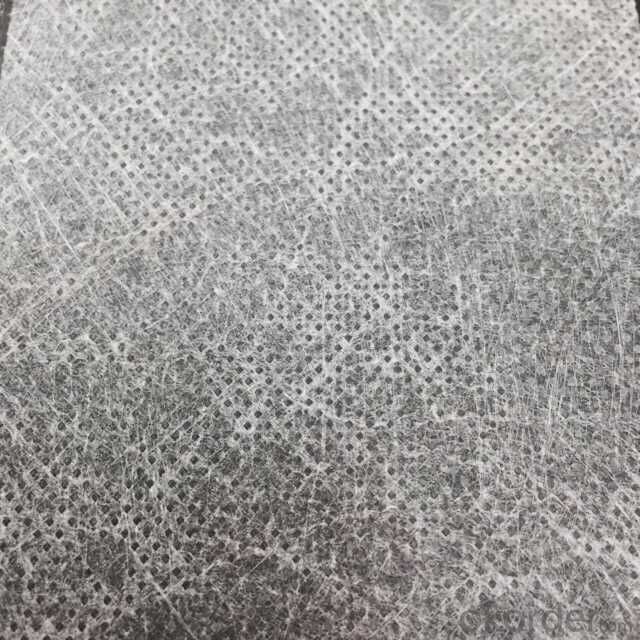

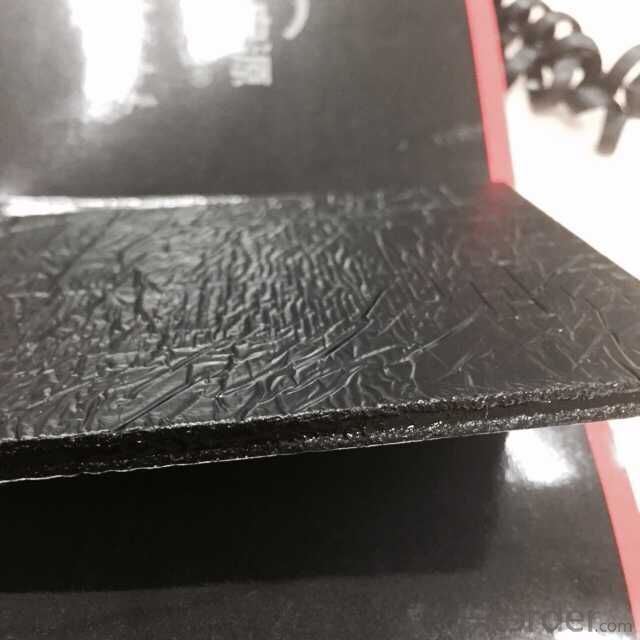

SBS(Styrene Butadiene Styrene) /APP (Atactic Polypropylene) modified bitumen membrane is made by saturating the base in bitumen, or thermoplastic elastomer (such as SBS, APP, APAO, APO), reinforced with polyester or fiberglass, finishing the upward face with polythene membrane, fine sands or mineral slates (or grains) or etc.

Specification Self-adhesive Bitumen Waterproof Membrane CMAX:

Thickness | 3mm, 4mm, 5mm |

Width | 1m |

length | 7.5m, 10m, 15m, or on demand |

Base | Polyester or Fiberglass felt |

Surface | PE film, Aluminum foil, Yellow sand, Shale gravel(Schist), colored sand |

Type | could self-adhesive |

Notice | SBS modified bitumen membrane is specially applied in the cold district, APP modified bitumen membrane is more suitable for hot district with high temperature. could be self-adhesive modified bitumen membrane |

Applications Self-adhesive Bitumen Waterproof Membrane CMAX:

-Roof and underground in industrial and civil buildings;

-Bridge, subway, tunnel, swimming pool, etc.

-Waste landfill, sewage plant, irrigation system, etc.

-Self-adhesive Modified Bitumen Waterproof Membrane

-Easy applying and economic on the cost saving

Advantage Self-adhesive Bitumen Waterproof Membrane CMAX:

-Non-solidified, excellent elastic deformation,thus have good noise reducing;

-Easy applying and economic on the cost saving.

-Good performance on waterproof and economic sound damping.

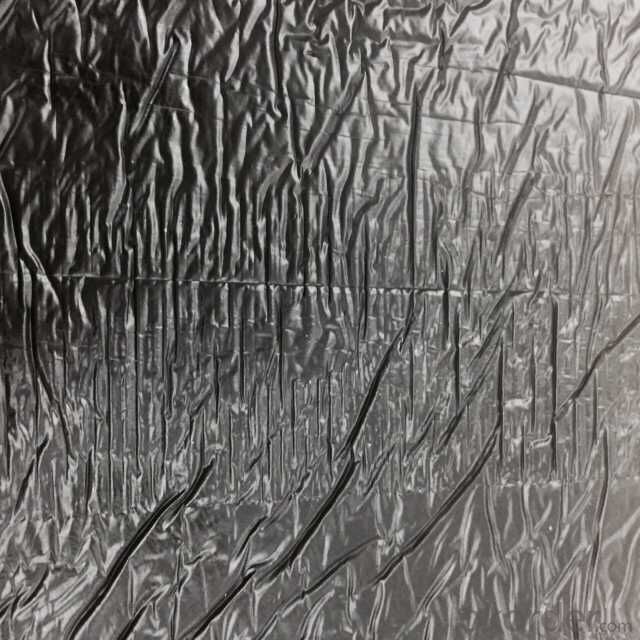

Picture Self-adhesive Bitumen Waterproof Membrane CMAX:

Storage Self-adhesive Ridge Ventilation Membrane for Roofing:

Shelf life is 12 months. Store in a cool and dry place with original packing.

Breathable Waterproof Roof Underlay membrane (PP-PP,S-PP,S-S)

Permeable membrane is polymer modified asphalt based, with surface of high strength polypropylene fiber. Back side coated with self adhesive glue or antiskid sand. Made by special process. With excellent waterproof performance and breathable properties.\

Description | Specification | Width | Length | Thickness | |

Roof underlay | 500g/m2PP—PP | 1000mm | 30m | 0.8mm | |

600g/m2S—PP | 1000mm | 25m | 1.0mm | ||

1500g/m2S—S | 1000mm | 20m | 1.3mm | ||

Roof underlay with adhesive band | 500g/m2PP—PP | 1000mm | 30m | 0.8mm | |

600g/m2S—PP | 1000mm | 25m | 1.0mm | ||

1500g/m2S—S | 1000mm | 20m | 1.3mm | ||

It is used as the underlayment of cement tile, painted pottery watts and asphalt shingle. Also suitable for all kinds of architectural roofing, walls, underground waterproof and damp proof project.

Features:

It has good waterproofing and ageing-resistance function,not flowing at highest temperature and no crack at lowest temperature;

Easy application,no pollution,and long service life etc.

Usage:

It is widely used for industry and civil building --- the waterproof and dampproof of the roofs,basements,toilets etc;and the waterproofing of bridges,parking area,tunnels,reserviors etc.

It is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions.

Requirements for surroundings

-The base should be dry and clean. Do not work in the rainy or snowy day.

-Do not work under heavy wind(above 5 grade)

-Unsuitable for construction below 0°C

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Does a waterproofing membrane provide any insulating properties?

- A waterproofing membrane does not offer any insulation. Its main purpose is to stop water or moisture from entering a building or roof. It acts as a protective barrier, preventing damage to the underlying materials. Insulation, on the other hand, is specifically designed to minimize the transfer of heat, sound, or electricity. While both waterproofing and insulation are crucial for maintaining a structure's integrity and functionality, they serve distinct purposes and should not be mistaken for each other.

- Q: Can a waterproofing membrane be used on EPDM roofs?

- EPDM roofs can benefit from the use of a waterproofing membrane. This synthetic rubber roofing material, known as EPDM, is popular for low-slope and flat roofs due to its durability and flexibility. Although EPDM roofs are already waterproof, adding a waterproofing membrane can offer an added layer of defense, increasing the roof's lifespan. By acting as a barrier against water infiltration, the waterproofing membrane prevents leaks and moisture-related harm. Nonetheless, it is crucial to guarantee that the chosen waterproofing membrane is compatible with EPDM and installed according to the manufacturer's instructions to preserve the roof's integrity.

- Q: Are waterproofing membranes resistant to water vapor transmission?

- Yes, waterproofing membranes are resistant to water vapor transmission. These membranes are designed to create a barrier that prevents water from penetrating through them. They are typically made from materials that are impermeable to water, such as rubber, plastic, or bitumen. This means that they effectively block the passage of liquid water, preventing it from seeping into the underlying structure. However, it is important to note that while waterproofing membranes can effectively resist water vapor transmission, they may not completely eliminate it. Some amount of water vapor may still pass through the membrane, but it is significantly reduced compared to other materials that are not designed for waterproofing purposes.

- Q: Can a waterproofing membrane be used on both horizontal and vertical surfaces?

- Yes, a waterproofing membrane can be used on both horizontal and vertical surfaces. Waterproofing membranes are designed to create a barrier against water penetration, regardless of the surface orientation.

- Q: Is a waterproofing membrane resistant to abrasion?

- Yes, a waterproofing membrane is generally designed to be resistant to abrasion. The membrane is typically made of durable materials that can withstand friction and wear, ensuring long-lasting protection against water damage.

- Q: How does a waterproofing membrane handle joint movement?

- To prevent water infiltration and maintain its effectiveness, a waterproofing membrane is specially crafted to handle joint movement. It accomplishes this by exhibiting flexibility and the ability to adapt to the expansion and contraction of joints. When joints experience movement due to factors like temperature fluctuations or settling of the structure, a waterproofing membrane must have the capability to stretch and compress without tearing or compromising its waterproofing properties. This is typically achieved through the utilization of elastomeric materials, such as rubber or synthetic polymers, which boast exceptional elongation and recovery properties. Moreover, waterproofing membranes may incorporate reinforcing materials, such as fabric or mesh, to enhance their tensile strength and their capacity to withstand joint movement. These reinforcements assist in distributing the stresses caused by joint movement, thus preventing localized damage and preserving the integrity of the membrane. Furthermore, certain waterproofing membranes possess special adhesive properties that enable them to tightly bond to the surfaces they are applied to, including the edges of joints. This adhesive bond plays a crucial role in establishing a continuous barrier against water penetration, even in the presence of joint movement. In summary, a waterproofing membrane is designed to exhibit flexibility and durability, ensuring effective management of joint movement, long-term protection against water intrusion, and the preservation of the structural integrity of the building or structure.

- Q: Can a waterproofing membrane be used for plant rooms?

- Yes, a waterproofing membrane can be used for plant rooms. Waterproofing membranes are commonly used in various applications, including plant rooms, to prevent water penetration and protect the structure from moisture damage. These membranes help maintain a dry and controlled environment, which is essential for the proper functioning and longevity of equipment in plant rooms.

- Q: Are waterproofing membranes suitable for balconies and terraces?

- Yes, waterproofing membranes are suitable for balconies and terraces as they provide an effective barrier against water infiltration, protecting the underlying structure from potential damage caused by moisture.

- Q: Can waterproofing membranes be used on roof decks?

- Indeed, roof decks can benefit from the use of waterproofing membranes. Specifically engineered to ward off water infiltration, these membranes prove to be an excellent option for safeguarding roof decks. Typically composed of materials like modified bitumen, thermoplastic, or rubberized asphalt, these membranes possess exceptional water resistance and possess the ability to effectively seal the surface of the roof deck. By applying a waterproofing membrane to a roof deck, it acts as a deterrent against water-related harm, leaks, and the decay brought about by moisture. Furthermore, these membranes can also provide extra defense against UV rays, temperature fluctuations, and other environmental variables, thereby prolonging the lifespan of the roof deck.

- Q: Can a waterproofing membrane be used in agricultural structures?

- Yes, a waterproofing membrane can be used in agricultural structures. It can help protect the structure from water damage, prevent moisture-related issues, and ensure a longer lifespan for the agricultural building.

Send your message to us

Self-adhesive Bitumen Waterproof Membrane CMAX

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords