Scaffolding Machine Formwork Scaffolding Hook CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Scaffolding Machine Formwork Scaffolding Hook CNBM

Plastic Formwork Concrete Formwork Scaffolding Manufacturer Scaffolding Spanners with New Design

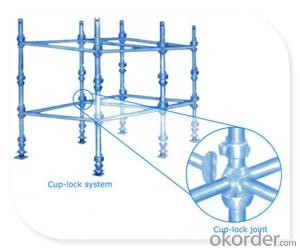

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks.

The advantages of plastic formworks:

Scaffolding Machine Formwork Scaffolding Hook CNBM

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

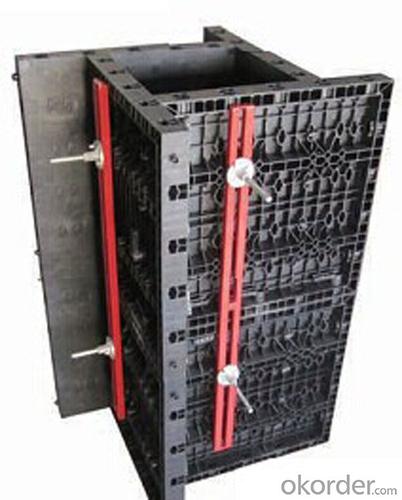

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

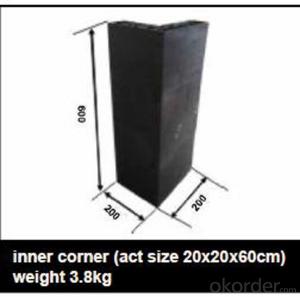

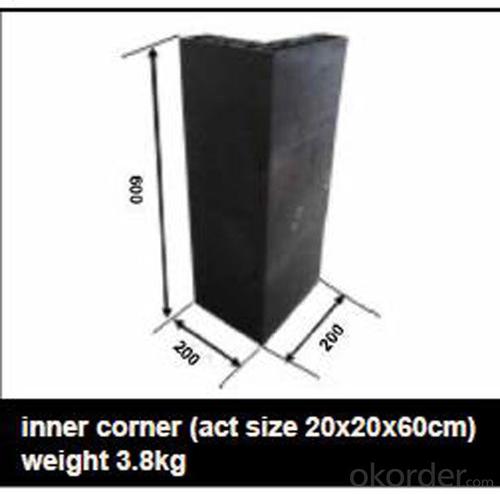

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Scaffolding Machine Formwork Scaffolding Hook CNBM

Scaffolding Machine Formwork Scaffolding Hook CNBM

Scaffolding Machine Formwork Scaffolding Hook CNBM

Scaffolding Machine Formwork Scaffolding Hook CNBM

- Q: How does steel frame formwork accommodate for different concrete surface finishes?

- Steel frame formwork is a versatile system that can easily accommodate different concrete surface finishes. One of the main advantages of using steel frame formwork is its flexibility in creating various surface textures and finishes. To achieve different concrete surface finishes, steel frame formwork can be customized by using different types of form liners, textures, or surface treatments. Form liners are commonly used to create patterns or textures on the concrete surface. These liners are made from various materials, such as rubber, plastic, or fiberglass, and can be easily attached to the steel formwork. For a smooth finish, the steel formwork can be lined with smooth form liners, allowing the concrete to set with a flat and uniform surface. On the other hand, if a textured or patterned finish is desired, form liners with specific designs can be used. These liners can create different textures, such as brick patterns, wood grains, or even unique designs. In addition to form liners, other surface treatments can be applied to the steel formwork to enhance the concrete surface finish. These treatments may include applying release agents, chemical retarders, or pigments to achieve specific effects. Release agents help in preventing the concrete from sticking to the formwork, allowing for easy removal and a smooth finish. Chemical retarders can be used to slow down the setting time of the concrete, which is beneficial for achieving exposed aggregate or textured finishes. Pigments can also be added to the concrete mix to introduce color and create visually appealing surfaces. Overall, steel frame formwork provides a flexible platform for achieving various concrete surface finishes. By using different form liners, textures, and surface treatments, the steel formwork can be customized to meet the desired finish requirements. This versatility makes steel frame formwork an ideal choice for projects where different surface finishes are desired.

- Q: What are the common material handling and storage practices for steel frame formwork systems?

- To ensure the safety and efficiency of construction, there are several key steps involved in handling and storing steel frame formwork systems. Consider the following practices: 1. Appropriate handling: To handle steel frame formwork systems properly, it is crucial to use suitable lifting equipment, such as cranes or forklifts. Trained personnel should operate these machines to prevent accidents or damage to the materials. 2. Storage conditions: Store steel frame formwork systems in a designated area that is clean, dry, and secure. Ensure the storage area is free from potential hazards like excessive heat, moisture, or direct sunlight, which can impact the integrity of the materials. Organize the formwork components to allow easy access and prevent damage. 3. Regular inspection: Regularly inspect steel frame formwork systems to identify signs of wear, corrosion, or damage. Conduct inspections before, during, and after each use, promptly addressing any issues to maintain safety and efficiency. 4. Cleaning and maintenance: Clean and maintain steel frame formwork systems properly to ensure longevity and optimal performance. Thoroughly clean formwork components after each use to remove concrete residue or debris. Perform regular maintenance tasks, such as lubricating moving parts, tightening fasteners, and repairing or replacing damaged or worn-out components. 5. Proper stacking and transportation: When storing or transporting steel frame formwork systems, stack the components correctly to prevent distortion or damage. Ensure stable and secure stacking with even weight distribution. During transportation, adequately secure the formwork systems to prevent any movement or shifting that could cause accidents or damage. By adhering to these common practices for material handling and storage, construction teams can contribute to the success of the construction project by ensuring the longevity, safety, and optimal performance of steel frame formwork systems.

- Q: Are there any environmental considerations associated with steel frame formwork?

- Steel frame formwork is associated with several environmental considerations. Firstly, the production of steel requires a significant amount of energy and resources, contributing to carbon emissions and environmental degradation. This makes the process of producing steel frame formwork carbon-intensive. Furthermore, steel is a non-renewable resource that cannot be easily replenished once it is used. This raises concerns about the depletion of natural resources and the long-term sustainability of steel frame formwork. Additionally, steel is prone to corrosion when exposed to moisture or chemicals, leading to the need for replacements and repairs. Disposing of old or damaged steel formwork also presents environmental challenges, as it contributes to landfill waste. On a positive note, steel frame formwork can be reused multiple times, reducing its overall environmental impact. However, the transportation and handling of heavy steel frames can still result in additional carbon emissions. To address these environmental considerations, alternative materials such as recycled plastic, bamboo, or timber should be considered for formwork. These materials are renewable, have lower carbon footprints, and can be easily reused or recycled. Additionally, implementing sustainable practices in the construction industry, such as waste reduction, optimized design, and improved energy efficiency, can help minimize the environmental impact of steel frame formwork.

- Q: What are the load-bearing capacities of steel frame formwork panels?

- The load-bearing capacities of steel frame formwork panels can differ based on various elements, including panel dimensions, thickness, steel type and quality, and formwork system design and construction. Generally, steel frame formwork panels are manufactured to endure significant loads and offer high load-bearing capacities. Typically, steel frame formwork panels can support heavy concrete loads, ranging from several hundred kilograms to several tonnes per square meter. The manufacturer usually specifies the load-bearing capacity, which can be affected by factors such as the spacing and strength of internal supports, the quality of welding or fastening joints, and the overall structural integrity of the system. To ensure safety and optimal performance, it is crucial to follow the manufacturer's guidelines and recommendations regarding load limits and maximum permissible loads for steel frame formwork panels. Consulting engineering and design professionals can assist in determining the specific load-bearing capacities necessary for a particular construction project, considering factors like intended use, dimensions, and structural requirements. In conclusion, steel frame formwork panels are designed to provide substantial load-bearing capacities, though the exact capacity can vary depending on several factors. It is important to refer to the manufacturer's specifications and seek professional advice to establish the appropriate load-bearing capacities for a specific formwork system.

- Q: Can steel frame formwork be used in areas with limited crane access?

- Indeed, areas with limited crane access can accommodate the use of steel frame formwork. This system, known for its adaptability and flexibility, permits manual adjustment and assembly. As a result, it is well-suited for areas where cranes face maneuverability challenges. The steel frames possess a lightweight quality, which enables a small team of workers to handle them effortlessly. Consequently, construction efficiency is maintained in regions with restricted crane access. Moreover, the modular design of steel frame formwork facilitates simple assembly and disassembly, thereby streamlining the construction process in areas with limited crane access.

- Q: How does steel frame formwork handle architectural features such as openings and recesses?

- Steel frame formwork is highly versatile and can easily handle architectural features such as openings and recesses. It allows for customization and precision in design, enabling the creation of various shapes and sizes. The steel frames can be easily adjusted, modified, or removed to accommodate specific architectural features, ensuring a seamless integration of openings and recesses within the overall structure.

- Q: Can steel frame formwork be used for both above-ground and below-ground concrete elements?

- Steel frame formwork is capable of being used for both above-ground and below-ground concrete elements. Renowned for its durability and strength, it is well-suited for diverse construction tasks. For above-ground elements like walls, columns, and beams, it serves as a means of support and shaping as the concrete cures. Additionally, the steel frame can withstand the pressure exerted by the wet concrete. When it comes to below-ground elements such as basements and foundations, steel frame formwork remains a feasible option. The inherent strength and rigidity of steel enable it to endure the pressure of the surrounding soil and groundwater, ensuring the stability and integrity of the structure. Moreover, steel formwork can be easily customized to accommodate intricate shapes and designs, rendering it suitable for a myriad of below-ground applications. In conclusion, steel frame formwork is a versatile solution that can be employed for both above-ground and below-ground concrete elements. Its strength, durability, and adaptability have established it as a favored choice in the construction industry for shaping and supporting concrete structures.

- Q: Can steel frame formwork be used for concrete slabs on grade?

- Certainly, concrete slabs on grade can indeed utilize steel frame formwork. This exceptional system, composed of steel panels or beams interconnected to form a framework, boasts remarkable versatility and durability, readily adaptable to various shapes and sizes. Its inherent stability and robustness effectively confine the concrete during pouring and curing, ensuring an impeccable outcome. Notably, this steel frame formwork facilitates efficient and accurate construction, guaranteeing superlative quality for the concrete slabs on grade. Furthermore, its reusability factor renders it an economically viable choice for concrete slab construction.

- Q: How does steel frame formwork affect the construction timeline?

- Steel frame formwork can have a significant impact on the construction timeline by speeding up the overall construction process. This is primarily due to the durability and efficiency of steel as a construction material. Firstly, steel frame formwork provides a stable and sturdy support system for concrete placement. It allows for precise and accurate pouring of concrete, ensuring uniformity and quality in the construction. This eliminates the need for additional time-consuming processes such as rework or repairs, which are often required with other formwork materials. Furthermore, steel frame formwork is reusable and can be easily assembled and disassembled, allowing for faster construction cycles. The quick assembly of steel frames reduces the time required for formwork installation and removal, thereby accelerating the overall construction timeline. Additionally, steel frame formwork is highly flexible and adaptable to different construction requirements. It can be customized and adjusted to fit various shapes and sizes, enabling efficient construction of complex structures. This versatility eliminates the need for multiple formwork systems, thereby reducing the time spent on formwork preparation. Moreover, steel frame formwork is highly resistant to weather conditions, making it suitable for use in various climates. This reduces the downtime caused by unfavorable weather conditions, allowing construction to progress uninterrupted. Overall, steel frame formwork streamlines the construction process by providing a robust, reusable, and adaptable solution. Its efficiency and durability contribute to the acceleration of the construction timeline, resulting in significant time and cost savings.

- Q: How does steel frame formwork handle the impact of vibrations during concrete pouring?

- Steel frame formwork is designed to handle the impact of vibrations during concrete pouring in a highly efficient manner. The steel structure provides excellent strength and rigidity, which helps to minimize the effects of vibrations. Additionally, the formwork is usually secured firmly to the ground or support structure, further enhancing its stability. During concrete pouring, vibrations are generated due to the pouring process itself, as well as the use of vibrating equipment to eliminate air pockets and ensure proper compaction. These vibrations can potentially cause the formwork to shift or become unstable, resulting in a compromised concrete structure. To counteract these vibrations, steel frame formwork often incorporates additional measures such as diagonal bracing or cross-bracing. These bracings help to reinforce the formwork system and distribute the vibrations more evenly, reducing the concentration of forces on any single point. Moreover, steel frame formwork is typically designed with adjustable components, allowing for precise alignment and leveling during the construction process. This adjustability enables the formwork to absorb and adapt to the vibrations, minimizing any potential impact on the concrete pouring. Overall, the robustness and stability of steel frame formwork make it well-suited to handle the impact of vibrations during concrete pouring. By providing a secure and rigid structure, alongside additional bracing and adjustability, steel frame formwork ensures that the concrete structure is not compromised, resulting in a high-quality and durable end product.

Send your message to us

Scaffolding Machine Formwork Scaffolding Hook CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches