Resin P500 - High Performance Resin

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20Ton m.t.

- Supply Capability:

- 5000 Ton/Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Property of Resin P500

• Resin P500 is a promoted and thixotropic toughness unsaturated polyester resins, which has perfect mechanical properties and higher elongation.

Applification of Resin P500

• FRP products such as tanks and pipelines.

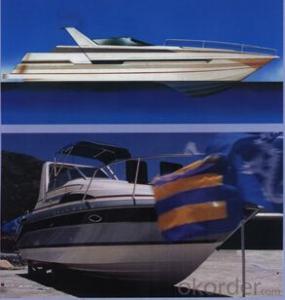

• FRP boats, such as fishing boat, marine/yacht, life boat, etc.

• Used in fabricating pultrusion molding tent pole, fishing rod, insulating rod, etc

• Can be used in filament winding, pultrusion, hand layup and spray-up process.

Spercification of Resin P500

|

Property |

Specification |

|

Epoxy Equivalent Weight (g/eq.) |

184-194 |

|

Viscosity (mPa.s @ 25°C ) |

11000-15000 |

|

Hydrolytic Chloride (mg/kg) |

≤300 |

|

Water Content (ppm) |

≤700 |

|

ECH Content (ppm) |

≤5 |

|

Color, APHA |

≤30 |

|

Volatile ( % ) |

≤0.1 |

|

Appearance |

Pale yellow oily liquid without obvious impurity |

|

Packaging: Epoxy Resins are packed in iron drum of 220±1kg or 20±0.1kg. | |

|

Storage: Should be stored at a ventilative, dry and clean place and far from fire and heating devices. | |

|

Transporting: Should be far from raining, direct sunlight, humidity and heating sources | |

Packing & Storage of Resin P500

• The product should be packed into clean, dry, safe and sealed container, net weight 220 Kg.

• Shelf life: four months below 25℃, stored in cool and well ventilated place.

- Q: What's the difference between alkyd anticorrosive paint and epoxy resin paint?

- The range of application of epoxy is basically in the ground floor (such as pharmaceutical factory, workshop, ground treatment), followed by metal surface corrosion protection

- Q: hi, its weird because I have only been a cashier for 2 months and I have noticed that my knuckels have been getting darkerdo you know of anything I can apply to lighten them? if u do please let me know..

- chain or cable lock could be wrapped under your seat around the seat post, and u locks could be locked on the bike around the top tube and down tube. or you could buy the evolution mini

- Q: A-la Netstreams, Colorado V-Net, Control 4, Lifeware or others. Not really interested in Crestron or AMX as my market isn't really that kind of market.

- So, my opinion on that is that your lady does not appreciate you AT ALL. My boyfriend simply acquired a role a couple of days in the past and I awoke whilst he did, wiped clean up and requested him what he desired for dinner whilst he acquired residence. If he's the only with a role and I'm no longer then my task is to preserve in which we are living. And when you consider that we shouldn't have a automobile correct now we do not quite spend cash except we're going out in combination to get groceries once we borrow someones automobile, if I desired to shop for anything and he wasn't residence I might textual content him. As for smoking within the residence for your ladies side if you do not smoke then that is beautiful rattling impolite to not point out that it ruins your residence it isn't well so that you can be round, and throwing the cigg butts out of a window? She has NO appreciate and regardless of his sometimes she does her nails she may have NO magnificence both. You have to inform her significantly that except she begins doing her side that you simply cannot have her dwelling there. You have to uncover a lady that cares approximately you and respects you and is aware that she has to take a few responsability for the location sh lives and the man or woman she is dwelling with. I'm sorry in case you love her and do not desire to depart her, however you should not be taking good care of her like she's a 4 12 months historic for the reason that that's precisely how she is performing.

- Q: Is there any danger in my showing and driving cars with customers while trying to sell them an auto?

- i recommend that you A) try to do a system restore B) if that doesn't work i think you should call up microsoft or the manufacturer of your computer good luck with your computer

- Q: Is the Israeli political system based on the Apartheid system?

- Nice idea. did you try scrapping with a razor blade? Or a utility knife blade? Try heating the area with your hair drier and use a putty knife to scrape it off. good luuck!

- Q: How many kinds of epoxy resin are there?What are the characteristics of each?

- Five major categories1. glycidyl ethers epoxy resins2. glycidyl epoxy resin3. glycidyl amine epoxy resin4. linear aliphatic epoxy resin5. alicyclic epoxy resin

- Q: Is it law for people to be wearing helmets while on motorcycles in the United States, specifically Virginia? I know it sounds weird, but I'm trying to crack down on a lie, and I'd also like know how much punishment would be received if someone was caught without their helmet.Thanks in advance!

- Ain't it funny how life works out? I was born in the USA at the end of a long and winding road in the small town of Soddy, Tennessee. We didn't have much money, but what we did have was stolen. Not that we were hardened criminals, it was just we believed in the equal division of assets. Pa wasn't very smart. He believed we had a phone cause he fell on his head stealing a washer from the K-Mart. He used to say Hey, the bells are ringing again, get the phone. That was one of the reasons no one would come on-a my house. It was full of Cereal People. You know fruits, flakes and nuts. Pa always said people who didn't lock up there valuables were like virgin with no pants on. Advertising what they didn't want to sell.

- Q: Anyone know a website who sells Face shield tear offs for motorcycle helmets? i know a lot of racing events use them. but any for just the normal everyday rider? cause im really tired of cleaning my face shield every other day. or any one know a good way to make some out of around the house stuff?

- braid your hair in two braids and put a hair tie at the ends and spray with hairspray and go to sleep with it like that and in the morning when you take the hair tie out your hair will be wavy..

- Q: if a fire hydrant has H2O inside, what does it have one the outside? (must be in correct format to win)

- I assume you're talking about clear epoxy or polyester resin that's often used by crafters, artists, users of fiberglass, etc? If so, no you can't make that kind of thing at home and it would be dangerous to try. If you're talking about other kinds of natural resin like pine sap, amber, etc, you can't really make those either. There may be other things you could make at home that would do some of the same things resins do though why don't you say a little more about exactly what kind of resin you're asking about and how are you wanting to use it? Diane B.

- Q: Let's face it, unless they will be living as hermits after school, they will have to face the dangers of the world after school and will not have the social skills to deal with the problems that they encounter.

- List . Product Description Timex gives its signature Ironman Triathlon multi-function, performance sport watch a sleek new look that's a great fit for both men and women. Featuring a full complement of athletic timing features and a striking profile, the Timex Triathlon Sleek T5D601 has a metallic silver resin case that's complemented by a uniquely styled, slim profile pink resin strap. It features three alarms that can be set for daily/weekday/weekend/weekly alarms, two time zones, an all-day white reflector display for easy reading even in direct sunlight, and water resistance to 100 meters. Sport timing functions include: * 100-hour chronograph with lap/split * On-the-fly recall of lap or split * Training log stores workouts by date, with best lap, average lap, and total segment time * Total run format/synchro timer maintains total activity time (less time paused during workout) and overall running time * Automatic interval repetition counter * Forward or backward setting * Built-in setting reminders * Top pusher for easy access to lap and split

1. Manufacturer Overview

| Location | Jiangsu,China |

| Year Established | 1958 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Resin P500 - High Performance Resin

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20Ton m.t.

- Supply Capability:

- 5000 Ton/Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords