Insulating Fire Brick - Refractory Mullite Insulating Refractory Brick JM 29

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

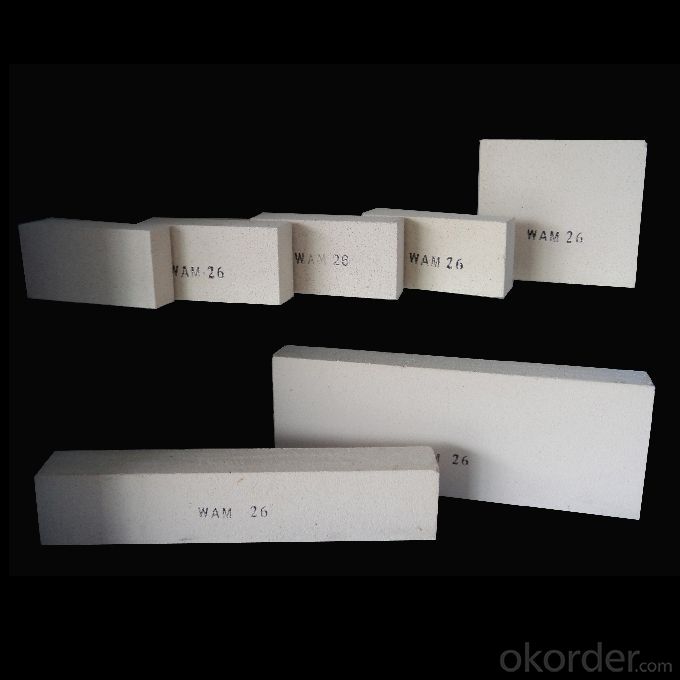

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application of Insulating brick

Metallurgical Industry: blast furnace, hot blast furnace, heating furnace, etc..

Petrochemical Industry: ethylene cracking furnace, hydrogen furnace, the main furnace, heating furnace, etc..

Ceramic industry: roller kiln, kiln, etc..

Glass industry: glass furnace regenerator, etc.

Carbon industry: carbon furnace, etc..

Aluminum electrolysis industry: aluminum reduction cell, etc.

Other industries: tunnel kiln, shuttle kiln, etc.

Advantages of heat insulation brick

Low thermal conductivity: many air holes will bring good thermal insulation effect, energy saving.

High crushing strength: high crushing strength, volume stability.

Low heat storage: small heat storage, absorb more heat, energy-saving effect is obvious.

Technical Data

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

Insulating brick

- Q: Are insulating fire bricks suitable for outdoor applications?

- Insulating fire bricks are generally not suitable for outdoor applications. These bricks are designed to be used in high-temperature environments such as kilns, furnaces, and other industrial applications. They have excellent thermal insulation properties and can withstand very high temperatures. However, insulating fire bricks are not designed to withstand exposure to the elements and can be easily damaged by moisture, rain, and extreme weather conditions. They are not resistant to freezing and thawing cycles, which can cause them to crack and break. For outdoor applications, it is recommended to use fire bricks that are specifically made for outdoor use. These bricks are usually made of dense clay or other materials that can withstand moisture and weather conditions. They are more durable and can provide better protection against the elements. It is important to consider the specific requirements and conditions of your outdoor application before choosing the appropriate type of fire bricks. Consulting with a professional or supplier knowledgeable in fire bricks can help ensure that you select the right product for your needs.

- Q: Can insulating fire bricks be used for insulation in oil refineries?

- Yes, insulating fire bricks can be used for insulation in oil refineries. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation. They are made from lightweight refractory materials that have low thermal conductivity, allowing them to effectively minimize heat transfer. In oil refineries, where high temperatures and heat transfer are common, insulating fire bricks can be used to insulate various components such as furnaces, reactors, and pipelines. By using insulating fire bricks, the heat loss can be significantly reduced, improving energy efficiency and reducing operational costs in oil refineries.

- Q: Can insulating fire bricks be used in the construction of heat storage units?

- Indeed, the utilization of insulating fire bricks is viable in the construction of heat storage units. These bricks are specifically engineered to endure extreme temperatures and possess exceptional thermal insulation properties. They are commonly employed in scenarios where heat retention holds significance, such as furnaces, kilns, and heat storage units. With their low thermal conductivity, these bricks effectively retain and preserve heat for extended durations, rendering them an ideal choice for heat storage units designed to capture and store heat energy for later usage. Additionally, these bricks are lightweight and easy to manipulate, making them a practical selection for construction projects. All in all, incorporating insulating fire bricks into the construction of heat storage units is a suitable and dependable option.

- Q: Can insulating fire bricks be used in textile industry kilns?

- Yes, insulating fire bricks can be used in textile industry kilns. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in kilns. In the textile industry, kilns are used for various processes such as dyeing, drying, and curing of fabrics. The use of insulating fire bricks in these kilns helps to maintain a consistent and controlled temperature, ensuring efficient and uniform heat distribution. Additionally, insulating fire bricks also help in reducing heat loss, leading to energy savings and improved operational efficiency. Therefore, insulating fire bricks are a suitable choice for textile industry kilns due to their thermal insulation properties and ability to withstand high temperatures.

- Q: Are insulating fire bricks resistant to salt attack?

- Insulating fire bricks do not typically possess resistance against salt attack, which refers to the deterioration and corrosion of materials caused by salt or saltwater exposure. Although insulating fire bricks are engineered to have exceptional thermal insulation properties, they are not specifically formulated to endure the damaging effects of salt. Salt attack has the potential to weaken the structure of the bricks, leading to a decrease in their performance and durability over time. If these bricks are consistently exposed to salt or saltwater, it is probable that their degradation will be hastened, making them unreliable for long-term use in such environments. To ensure resilience against salt attack, it is advised to utilize refractory materials specially designed for this purpose, such as salt-resistant fire bricks or refractories with a higher alumina content. These materials have been developed to withstand the corrosive impacts of salt and are better suited for applications where exposure to salt or saltwater is anticipated.

- Q: Can insulating fire bricks be used in high-temperature insulation blankets for aerospace applications?

- Yes, insulating fire bricks can be used in high-temperature insulation blankets for aerospace applications. Insulating fire bricks are known for their ability to withstand high temperatures and provide excellent insulation properties. By incorporating them into insulation blankets, they can effectively protect against heat transfer and maintain thermal stability in aerospace applications.

- Q: Can insulating fire bricks be cut or shaped to fit different spaces?

- Yes, insulating fire bricks can be cut or shaped to fit different spaces. They are typically made from a soft, lightweight material that can be easily cut or shaped using common tools like saws or knives. This flexibility allows for customization and adaptation to various spaces and applications.

- Q: Can insulating fire bricks be used in drying ovens?

- Yes, insulating fire bricks can be used in drying ovens. Insulating fire bricks are designed to have low thermal conductivity, which makes them an excellent choice for applications that require heat insulation, such as drying ovens. These bricks can withstand high temperatures and provide insulation to help maintain the desired temperature inside the oven, while also reducing heat loss to the surroundings. Additionally, insulating fire bricks are lightweight and easy to install, making them a practical choice for use in drying ovens.

- Q: Can insulating fire bricks be used for insulation in boilers?

- Yes, insulating fire bricks can be used for insulation in boilers. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. They have low thermal conductivity, meaning they can effectively reduce heat loss and improve the energy efficiency of boilers. Additionally, insulating fire bricks are lightweight and easy to install, making them a popular choice for insulation in boilers. They can help maintain high temperatures inside the boiler, allowing for efficient combustion and heat transfer, while also protecting the outer structure from excessive heat. Overall, insulating fire bricks are a reliable and effective choice for insulation in boilers.

- Q: Can insulating fire bricks be used for insulation in steam pipes?

- Yes, insulating fire bricks are a suitable option for insulation in steam pipes. These bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. They have low thermal conductivity, which means they prevent the transfer of heat effectively. This property makes them ideal for insulating steam pipes, as it helps to minimize heat loss and maintain the temperature of the steam inside the pipes. Additionally, insulating fire bricks are lightweight and easy to install, making them a convenient choice for insulating steam pipes.

Send your message to us

Insulating Fire Brick - Refractory Mullite Insulating Refractory Brick JM 29

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords