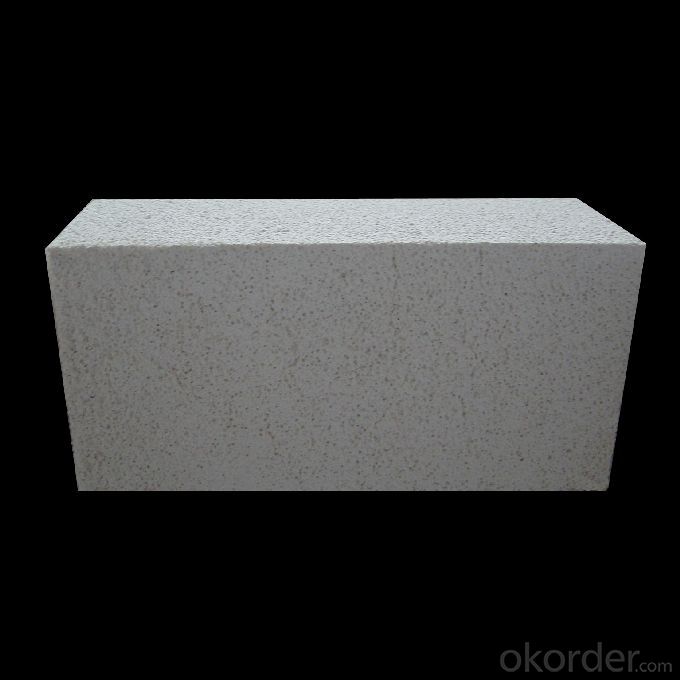

Insulating Fire Brick - Refractory Mullite Insulating Refractory Brick JM 35

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Okorder series heat insulation brick

Okorder series thermal insulation brick is an effective, energy saving, low carbon, environmental protection advanced, according to the ASTM standard manufacturing products. Okorder series products have all kinds of materials in the field of metallurgy, industrial furnaces, aluminum, the best Li Ning petrochemical and insulation, electric power and glass ceramics. They can be used as part of an insulation or not to melt. Products have been widely used in the following furnace, achieved satisfactory results.

Application of heat preservation brick

Metallurgical Industry: blast furnace, hot blast furnace, heating furnace, etc..

Petrochemical Industry: ethylene cracking furnace, hydrogen furnace, the main furnace, heating furnace, etc..

Ceramic industry: roller kiln, kiln, etc..

Glass industry: glass furnace regenerator, etc.

Carbon industry: carbon furnace, etc..

Aluminum electrolysis industry: aluminum reduction cell, etc.

Other industries: tunnel kiln, shuttle kiln, etc..

Advantages of heat insulation brick

Low thermal conductivity: many air holes will bring good thermal insulation effect, energy saving.

High crushing strength: high crushing strength, volume stability.

Low heat storage: small heat storage, absorb more heat, energy-saving effect is obvious.

Chundu: High-speed Rail, low content of alkali metal impurities.

Accuracy: the size of the brick machining precision, cutting and grinding the special shape, speed up the brick.

Technical Data

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

Insulating brick

- Q: Are insulating fire bricks resistant to fluorine gas?

- Insulating fire bricks are not typically resistant to fluorine gas. Fluorine gas is highly reactive and corrosive, and it can react with various materials, including insulating fire bricks. The corrosive nature of fluorine gas can cause damage to the structure and integrity of the fire bricks, leading to their deterioration or failure over time. Therefore, it is advisable to choose a different type of refractory material that is specifically designed to withstand the corrosive effects of fluorine gas if it is required for a particular application.

- Q: Can insulating fire bricks be used in the construction of lime recovery kilns?

- Yes, insulating fire bricks can be used in the construction of lime recovery kilns. Lime recovery kilns are high-temperature industrial furnaces used to convert limestone (calcium carbonate) into lime (calcium oxide) through a process called calcination. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation. They are made from lightweight refractory materials, such as clay or silica, and have low thermal conductivity. In lime recovery kilns, where temperatures can reach up to 900-1200 degrees Celsius, insulating fire bricks can be used to line the walls, floors, and roofs of the kiln. Their high insulating properties help to reduce heat loss and improve energy efficiency by keeping the heat inside the kiln. This leads to lower fuel consumption and cost savings. Furthermore, insulating fire bricks have good resistance to thermal shock, which is crucial in the lime recovery process. The kilns undergo repeated heating and cooling cycles, and the bricks must be able to withstand these temperature changes without cracking or disintegrating. Overall, insulating fire bricks are a suitable choice for lime recovery kilns due to their ability to withstand high temperatures, provide thermal insulation, and resist thermal shock.

- Q: Can insulating fire bricks be used in metal melting furnaces?

- Indeed, metal melting furnaces can utilize insulating fire bricks. Specifically tailored to endure high temperatures and offer exceptional insulation, these bricks prove to be an optimal selection for applications such as metal melting furnaces. These bricks possess a low thermal conductivity, which aids in heat preservation and diminishes energy usage. Furthermore, insulating fire bricks are lightweight, long-lasting, and capable of withstanding thermal shock, rendering them a fitting choice for the severe conditions experienced in metal melting furnaces.

- Q: Can insulating fire bricks be used in the construction of pottery molds?

- Yes, insulating fire bricks can be used in the construction of pottery molds. Insulating fire bricks are made from lightweight refractory materials that have excellent heat insulation properties. These bricks are specifically designed for applications that require high temperatures, such as pottery kilns. When constructing pottery molds, it is important to have materials that can withstand the intense heat of the kiln. Insulating fire bricks can withstand temperatures up to 3000°F (1650°C), making them suitable for pottery mold construction. They provide insulation to prevent heat loss and maintain consistent temperatures inside the kiln, which is essential for achieving the desired firing results. Furthermore, insulating fire bricks can be easily shaped and cut to fit the desired mold design. They are also lightweight, which makes them easier to handle during the mold construction process. Additionally, the insulating properties of these bricks help to reduce energy consumption by preventing excessive heat loss, making them cost-effective in the long run. Overall, insulating fire bricks are a suitable choice for constructing pottery molds due to their ability to withstand high temperatures, provide insulation, and be easily shaped to fit specific designs.

- Q: Is it possible to recycle used insulating fire bricks?

- Yes, it is possible to recycle used insulating fire bricks. These bricks can be crushed, ground, or shredded, and then the resulting material can be used as a raw material in the production of new bricks or as an aggregate in construction materials. Recycling used insulating fire bricks helps to reduce waste and conserve resources.

- Q: Can insulating fire bricks be used for insulation in foundries?

- Yes, insulating fire bricks can be used for insulation in foundries. Insulating fire bricks are specifically designed to have high thermal resistance and low thermal conductivity, making them ideal for applications where insulation is required. In foundries, where high temperatures are involved, insulating fire bricks can be used to line the walls, floors, and roofs to reduce heat loss and improve energy efficiency. They can also help to maintain a uniform temperature throughout the foundry, ensuring consistent heat distribution and preventing heat loss to the surroundings. Additionally, insulating fire bricks are lightweight and easy to install, making them a practical choice for insulation in foundries.

- Q: Can insulating fire bricks be used in rocket stove designs?

- Insulating fire bricks are capable of being incorporated into the designs of rocket stoves. Rocket stoves are renowned for their efficient combustion and heat transmission, and the utilization of insulating fire bricks can enhance this level of performance. These bricks are produced from lightweight materials that possess excellent insulating properties, allowing them to effectively retain and reflect heat. The combustion chamber of a rocket stove is typically lined with insulating fire bricks in order to maximize the transfer of heat to the cooking surface or the area being heated. The bricks aid in the retention of heat within the combustion chamber, ensuring that a greater portion of the energy generated from the burning fuel is utilized to heat the cooking surface, rather than being dissipated into the surrounding environment. Moreover, insulating fire bricks are capable of enduring high temperatures, making them an ideal choice for inclusion in rocket stove designs. They are specifically engineered to withstand the intense heat generated by the combustion process, guaranteeing that the bricks will not fracture or shatter under such circumstances. In conclusion, the incorporation of insulating fire bricks into the designs of rocket stoves can enhance the efficiency and heat transmission of the stove, resulting in a more efficient and sustainable solution for cooking or heating purposes.

- Q: What is the typical moisture content of an insulating fire brick?

- The typical moisture content of an insulating fire brick can vary depending on several factors such as the specific composition of the brick, the manufacturing process, and the storage conditions. However, in general, insulating fire bricks are designed to have a low moisture content to enhance their insulating properties and resistance to thermal shock. Typically, insulating fire bricks have a moisture content ranging from 0.5% to 2%. This low moisture content helps to prevent the bricks from cracking or spalling when exposed to high temperatures. It also minimizes the risk of moisture-related damage, such as freeze-thaw cycles or the release of steam when heated. To ensure the optimal performance and longevity of insulating fire bricks, it is recommended to store them in a dry environment and protect them from moisture during transportation and installation.

- Q: Can insulating fire bricks be used in refractory lining for steelmaking?

- Insulating fire bricks can indeed be utilized for refractory lining in the steelmaking industry. Crafted from lightweight ceramic materials, these bricks possess remarkable thermal insulation properties. Consequently, they prove to be highly suitable for applications involving elevated temperatures, such as steelmaking, where the maintenance of a consistent temperature is of utmost importance. By incorporating insulating fire bricks, heat loss can be minimized, energy efficiency can be enhanced, and insulation against the extreme temperatures encountered in steel production can be provided. Moreover, these bricks exhibit resistance to thermal shock, a vital characteristic for withstanding sudden temperature fluctuations during the steelmaking process. Consequently, the utilization of insulating fire bricks within refractory lining for steelmaking purposes can significantly optimize the performance and efficiency of the entire steelmaking operation.

- Q: Do insulating fire bricks require any special anchors or supports for installation?

- Yes, insulating fire bricks do require special anchors or supports for installation in certain applications. Insulating fire bricks are lightweight and have low thermal conductivity, making them ideal for use in high-temperature environments such as furnaces, kilns, and fireplaces. However, due to their lightweight nature, they can be prone to movement or displacement under certain conditions. To ensure the stability and integrity of the insulating fire bricks, it is recommended to use special anchors or supports during installation. These anchors or supports are typically made of metal, such as stainless steel, and are designed to securely hold the bricks in place. They help prevent the bricks from shifting or falling out, especially when exposed to vibrations, thermal expansion/contraction, or other external forces. The type and design of the anchors or supports depend on the specific application and installation requirements. Common types of anchors include V anchors, U anchors, and L anchors, which are embedded into the surrounding refractory material or attached to a structural frame. The anchors or supports should be properly spaced and installed according to the manufacturer's guidelines to ensure adequate support and stability of the insulating fire bricks. In summary, while insulating fire bricks offer excellent thermal insulation properties, they do require special anchors or supports for installation in order to prevent movement or displacement. These anchors or supports play a crucial role in maintaining the structural integrity and longevity of the insulating fire brick system.

Send your message to us

Insulating Fire Brick - Refractory Mullite Insulating Refractory Brick JM 35

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords