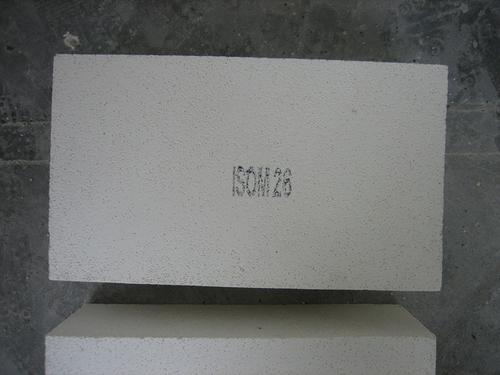

Insulating Fire Brick - Refractory Mullite Insulating Refractory Brick JM 26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application of Insulating brick

Metallurgical Industry: blast furnace, hot blast furnace, heating furnace, etc..

Petrochemical Industry: ethylene cracking furnace, hydrogen furnace, the main furnace, heating furnace, etc..

Ceramic industry: roller kiln, kiln, etc..

Glass industry: glass furnace regenerator, etc.

Carbon industry: carbon furnace, etc..

Aluminum electrolysis industry: aluminum reduction cell, etc.

Other industries: tunnel kiln, shuttle kiln, etc.

Advantages of heat insulation brick

Low thermal conductivity: many air holes will bring good thermal insulation effect, energy saving.

High crushing strength: high crushing strength, volume stability.

Low heat storage: small heat storage, absorb more heat, energy-saving effect is obvious.

Technical Data

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

Insulating brick

Common problem solution

1. What products do you have?

We have all kinds of refractory bricks, refractory casting materials, mortar, cement, ceramic fiber products, etc..

Or you can browse our products to choose what you need.

2. How to control product quality?

With strict quality control system throughout the material selection and production process, we have the quality of refractory materials and ceramic fiber products to meet customer requirements.

From the selection of raw materials, the quality of our control to start. The quality of the raw materials required for each batch of products in the use of the front line test. In the production process, through the quality control of workers, and then to each piece of classification, and through quality supervision and inspection.

3. Could you give me a brief introduction to the application of your product?

My Company is mainly engaged in steel, cement, glass, ceramics, petrochemical, electric power and other industries.

4. If I need you, what kind of information do you need?

In order to select the right products, we will provide us with information, such as the United States, technical data, order quantity, product applications, etc..

If you have any questions, please contact us.

- Q: Are insulating fire bricks resistant to fluorine gas?

- Insulating fire bricks are not typically resistant to fluorine gas. Fluorine gas is highly reactive and corrosive, and it can react with various materials, including insulating fire bricks. The corrosive nature of fluorine gas can cause damage to the structure and integrity of the fire bricks, leading to their deterioration or failure over time. Therefore, it is advisable to choose a different type of refractory material that is specifically designed to withstand the corrosive effects of fluorine gas if it is required for a particular application.

- Q: Can insulating fire bricks be used in the construction of ladles?

- Yes, insulating fire bricks can be used in the construction of ladles. These bricks are designed to withstand high temperatures and provide excellent thermal insulation. They are commonly used in industrial applications such as ladle lining to maintain heat and prevent heat loss, ensuring efficient and safe operations in metal casting and foundry processes.

- Q: Do insulating fire bricks require any special fireproofing treatments?

- There is no need for any special fireproofing treatments for insulating fire bricks. Insulating fire bricks are composed of lightweight materials that possess excellent insulation properties, such as refractory clay or ceramic fibers. These materials possess inherent fire resistance and can endure high temperatures without requiring extra fireproofing treatments. Nevertheless, it is crucial to guarantee the correct installation and utilization of insulating fire bricks in order to enhance their efficiency and lifespan.

- Q: Can insulating fire bricks be used for insulation in industrial chimneys?

- Indeed, insulating fire bricks have the capability to serve as insulation in industrial chimneys. These bricks are specially crafted to endure extreme temperatures and offer exceptional insulation characteristics. Comprised of lightweight refractory materials boasting low thermal conductivity, insulating fire bricks successfully retain heat and hinder its dispersion into the environment. Consequently, they prove to be optimal for employment in industrial chimneys, as insulation plays a vital role in diminishing heat loss and enhancing energy efficiency. Furthermore, insulating fire bricks exhibit resistance against chemical corrosion, rendering them well-suited for the hostile and corrosive settings frequently encountered in industrial chimneys.

- Q: How do insulating fire bricks help improve the efficiency of heat recovery systems?

- Insulating fire bricks are essential for improving the efficiency of heat recovery systems in multiple ways. To begin with, these bricks are crafted from top-notch insulating materials like ceramic fiber, which possess exceptional thermal properties. This implies that they exhibit a low thermal conductivity, thus preventing the escape or wastage of heat. By incorporating insulating fire bricks as lining materials in heat recovery systems, the heat exchange process becomes more efficient as less heat is lost to the surroundings. Furthermore, insulating fire bricks aid in reducing heat transfer through conduction. They serve as a barrier between the hot and cold sides of the system, thereby minimizing heat loss through direct contact. This insulation effect enables the heat recovery system to maintain a higher temperature on the hot side, maximizing the temperature difference and ultimately enhancing the rate of heat transfer. In addition, these fire bricks are lightweight and possess low heat storage capabilities. Consequently, they require less energy for heating and cooling, resulting in faster response times for the heat recovery system. This quick response enables the system to adapt swiftly to changes in heat generation or demand, thereby improving its overall efficiency. Moreover, the utilization of insulating fire bricks as refractory materials in heat recovery systems aids in reducing energy consumption. Since these bricks can withstand high temperatures without cracking or deforming, they contribute to the system's longevity, reducing the need for frequent repairs or replacements. This leads to lower maintenance costs and less downtime, ultimately enhancing the overall energy efficiency of the heat recovery system. To summarize, insulating fire bricks bolster the efficiency of heat recovery systems by providing superb thermal insulation, minimizing heat loss through conduction, enabling rapid response times, and reducing energy consumption. Their incorporation as lining materials significantly enhances the heat transfer process, resulting in more effective heat recovery and utilization.

- Q: Do insulating fire bricks have good mechanical strength?

- Yes, insulating fire bricks have good mechanical strength. They are specifically designed to withstand high temperatures and provide excellent thermal insulation while maintaining their structural integrity.

- Q: Are insulating fire bricks suitable for use in furnaces?

- Yes, insulating fire bricks are suitable for use in furnaces. They have excellent thermal insulation properties, high temperature resistance, and can withstand the harsh conditions inside a furnace without cracking or breaking. These bricks help to maintain consistent temperatures, reduce heat loss, and improve energy efficiency in furnaces.

- Q: Can insulating fire bricks be used in rotary kilns?

- Rotary kilns can indeed utilize insulating fire bricks. These bricks are specifically designed to possess low thermal conductivity, enabling them to withstand high temperatures while minimizing heat loss. Consequently, they are well-suited for employment in rotary kilns, which are utilized across various industries for processes like calcination, sintering, and roasting. The application of insulating fire bricks within rotary kilns effectively contains the internally generated heat, resulting in enhanced energy efficiency and cost savings. Moreover, these bricks' insulating properties aid in reducing the temperature on the kiln's outer surface, thereby ensuring a safer working environment for operators. Ultimately, insulating fire bricks serve as an ideal choice for rotary kilns, offering remarkable thermal insulation and contributing to the kiln's overall performance and durability.

- Q: Is it necessary to use mortar when installing insulating fire bricks?

- Yes, it is necessary to use mortar when installing insulating fire bricks. Mortar acts as a bonding agent between the bricks, ensuring stability and preventing heat loss. It also helps to seal any gaps or cracks, enhancing the insulation properties of the bricks.

- Q: Can insulating fire bricks be used in biomass power plants?

- Yes, insulating fire bricks can be used in biomass power plants. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for lining furnaces and boilers in biomass power plants. They help to increase energy efficiency by minimizing heat loss, ensuring optimal combustion, and reducing the overall energy consumption of the plant.

Send your message to us

Insulating Fire Brick - Refractory Mullite Insulating Refractory Brick JM 26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords