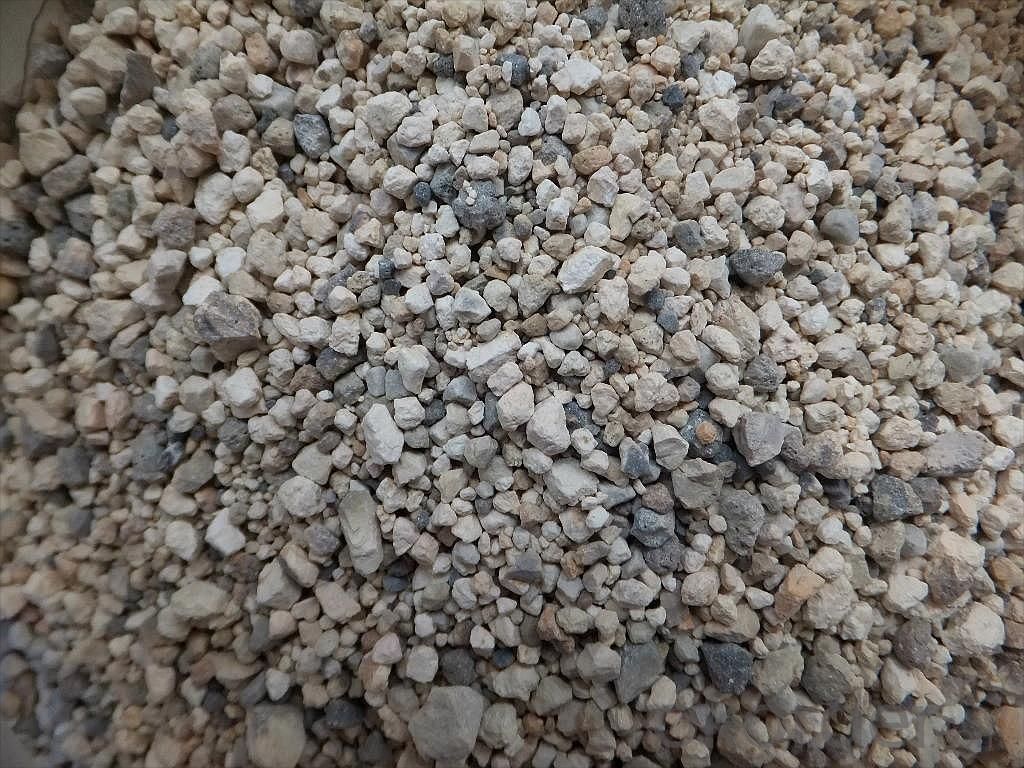

Raw Materials for Refractory:Rotary/Round/Shaft Kiln Calcined Bauxite 86 - Made in China for Low Price Refractory Applications

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DESCRIPTION

QUIKE DETAILS

| Place of Origin: | Henan, China (Mainland) | Shape: | Block , Powder | Material: | Bauxite |

| SiO2 Content (%): | 8% Max | Al2O3 Content (%): | 86%Min | Fe2O3 Content (%): | 2%Max |

| CaO Content (%): | CaO+MgO<0.6< span=""> | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | International standard |

| SiC Content (%): | International standard | Model Number: | 80# 85# 86# 87# | Brand Name: | CNBM |

SIZES

| GRAIN | normaly 0-1/1-3/3-5mm,or as per customers' request |

| POWDER | -200/-220/-325mesh,or as per customers' request |

OTHER GRADES OF RKB

GRADE | CHEMICAL CONTENT,% | PHYCICAL PROPERTIES | |||||

Al2O3,% | Fe2O3,% | TiO2,% | CaO+MgO,% | R2O,% | DENSITY, g/cm3 | WATER ABSORPTION,% | |

GAL-70 | ≥70 | ≤2.0 | - | ≤0.6 | ≤0.6 | ≥2.75 | ≤5.0 |

GAL-80 | ≥80 | ≤2.0 | ≤4.0 | ≤0.5 | ≤0.5 | ≥2.90 | ≤5.0 |

GAL-85 | ≥85 | ≤1.8 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.10 | ≤4.0 |

GAL-88 | ≥88 | ≤1.5 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.15 | ≤4.0 |

GAL-88HG | ≥88 | ≤1.5 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.25 | - |

PACKAGING & DELIVERY

| Packaging Details: | JUMBO BAGS/WOVEN BAGS/ PAPER BAGS (pallets) or as per customers' request! |

| Delivery Detail: | 25 days after buyer's instruction. |

PICTURES

COMPANY PROFILE

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

Since 2004, the trading volume of CNBM International has been doubled in 5 successive years owing to the support of superior corporations and effort of all staff. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target.

In line with the business, CNBM International launched E-business platform Okorder.com.

With the advantages in Cement, Composite Materials, New Building Materials and Engineering, we mainly concentrate on coal, steel and construction equipments and give priority to solar and wind energy development simultaneously utilizing our competitive position on traditional building materials to achieve sales revenue of RMB10 Billion in 2013.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

On July 7th, the US Fortune magazinepublishedthe 2014 Ranking List of World Top 500 Enterprises. China National Building Materials Group Corporation (CNBMGroup in short) enters into the Fortune Global 500 for the fourthsuccessive time withits operating revenue of 41.03 billion USD, ranking the 267th place, and rising 52 places over last year. Amongst the three building materials enterprises listed in the Fortune Global 500, CNBM ranks the second with promising momentum.

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

We promise the best cargo and the best service!

- Q: Can anyone tell me the requirements of the refractory masonry??

- Kaolin is mainly composed of kaolinite crowded minerals that is in the shpe of tiny flake which is less than two microns, tube and folding flake. The kaolinite crowded mineral consists of kaolinite, dickite, pearl stone, halloysite, etc. and its ideal chemical formula is AL2O3-2SiO2-2H2O. The main mineral component of it is kaolinite and halloysite.In addition to the kaolinite crowded mineral, kaolin is accompanied by other minerals like montmorillonite, illite, pyrophyllite, quartz and feldspar. The chemical composition of kaolin contains large amounts of AL2O3, SiO2, and a small amount of Fe2O3, TiO2, and traces of K2O, Na2O, CaO and MgO, etc. The white pottery is made of kaolin. At present, the internationally accepted scientific name for kaolin is Kaolin which is derived from the kaolin mountain in the eastern suburb of kaolin village in Jingdezhen.Such special properties of kaolin as its plasticity,cohesiveness, certain dry strength, sinterability and firing whiteness make it the main raw material for ceramic production; properties like whiteness, softness, high dispersibility, and adsorbability allows it to be widely used the paper industry. In addition, the kaolin is also widely used in some industrial sectors such as rubber, plastics, refractories, oil refining as well as agriculture sector and cutting-edge technology for national defense. According to the purpose and requirements, kaolin can be processed and purified and it can be used to manufacture activated clay.

- Q: What refractories have good mechanical property resistance and heat expansion and cold contraction property?

- Explain that where you use it for and what requirements you have. Follow-up: I use it in metallurgical furnaces with the features of strong stirring and acidic residue.

- Q: What is the function of refractory in ceramics?

- Refractory is used as materials of kiln,sagger and kiln car for ceramic sintering. Its refractoriness is higher than ceramics, and the essential material and tool for ceramic sintering.

- Q: What are the characteristics of magnesium fireproof plate

- Fire Excellence: Glass magnesium plate is non combustible plate having good fire-resisitance quality. Flame will never burn continuously on it. It does not catch on fire when temperature reach 800 ℃, and will not be lit up at 1200 ℃. The plate, having high-quality keel partition system, is rated as the highest non-combustible level A1 with fire resistance being above 3 hours. It absorbs a lot of heat when fire is burning, delaying rise of ambient temperature. Waterproof and moisture proof: Glass magnesium plate functions steadily whenever weather is dry and cold or humid and damp, not influenced by condensed water drop and moist air. Even air dried after soaked in water for a few days, no deformation, it will not go out of shape, turn soft, or absorb moisture After testing, the board has no water permeability. Light weight and seismic resistance: Low overall plate density of 0.8-1.2g/cm3 reduces the building's load, and the weight of building interior wall by over 60%, and increases the use area by 5-8%. Its lightweight is conducive to anti-seismic, can effectively reduce main cost of foundation and structure. Superior strength: Magnesite has special 5.1.8 phase covered fiberglass cloth and good toughness of plant fiber. Altough glass magnesium fireproof plate is light, it has tight structure, good stability, wood-like toughness, outstanding performance in impact resistance, compressive strength, tensile strength equal rigidity and toughness, with flexural strength up to 322kgf\cm2 (vertical) and 216kgf\cm2 (level of) as well as impact strength of 25MPa.

- Q: What are the features of construction class A fire resistant door ?

- 1, fireproof and thermal insulation Foam cement board is a Class A non-combustible inorganic heat preservation material which has good fireproof?performance can remain integrity after 3 hours baking at 1200℃. It can be used in buildings to improve fireproof?performance.

- Q: what's the fire endurance of fireproof?panel?

- fire endurance of fireproof?panel can reach 3 hours. For example, 12 mm non-asbestos fiber reinforced calcium silicate board, fireproof?panel, two single 75 keel. through the monitoring of national fireproof construction materials quality supervision center, it's security and refractory time will reach over 3 hours. fireproof?panel, also called fire resistance board, scientific name is thermosetting resin impregnated paper laminated wood,english abbreviation HPL(Decorative High - pressure Laminate) is fire resistant building material for surface decoration and has rich surface colors,lines and special logistics performance, it's widely used in interior decoration, furniture, cabinets, laboratory table, external wall, etc.

- Q: Why do magnesium oxide refractory bricks can be made into refractories?

- The substance used in refractories must have the following characteristics and properties: 1, High stability: Anti-oxidation, anti-reduction and thermal decomposition; 2, High melting point of 2800 degree; 3, Low price. The magnesium oxide refractories have all these three characteristics and properties, particularlly in the aspects of melting point and stability .

- Q: What level is the rock wool board fireproofing material ?

- The fire rating classification is a provision for all insulation materials, rather than to separately divide rock wool. Determine the value of the material fire rating according to the relevant test items of 8624. As the rock wool is made from basalt fusion, so it is the level A non-combustible material.

- Q: can slag tailings be used to be the base materials of refractory materials ?

- the rest of it can be used as refractory additives. the scale currently used clay bricks to make high-temperature liquid. It is easy to produce large amounts of liquid because of the high iron content, instead of its refractoriness. But it can be used as refractory minaralizer.

- Q: what's the detailed address of fireproof and thermal inuslation matertial market?

- Detailed address of fire insulation materials market is as follows: A: Guangzhou Huatai building materials co., LTD. Address: Guangzhou Tianhe Chepo Road no. 10 B: Address of Donglong building materials market: Guangzhou Tianhe Taian North Road no. 7 C: Address of Huiya building materials trade market : Guangzhou Tianhe Sports West Road No. 109

Send your message to us

Raw Materials for Refractory:Rotary/Round/Shaft Kiln Calcined Bauxite 86 - Made in China for Low Price Refractory Applications

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords