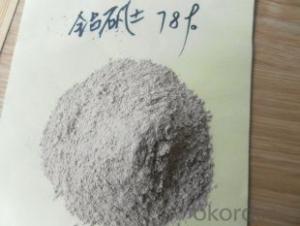

Raw Materials for Refractory:Calcined Bauxite Rotary Kiln Al2O3 86%

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Metric Ton/Metric Tons m.t.

- Supply Capability:

- 20000 Metric Ton/Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Calcined Bauxite Rotary Kiln Al2O3 86% :

Place of Origin:China mainland

Material:Alumina block

Al2O3 Content(%):86%min

Refractoriness(Degree):1770℃<Refractoriness<2000℃

Shape:Block

Specifications of Calcined Bauxite Rotary Kiln Al2O3 86% :

|

Al2O3 |

86%min | ||

|

SiO2 |

8.5%max |

|

|

|

Fe2O3 |

2.0%max | ||

|

TiO2 |

4.0%max | ||

|

CaO+MgO |

0.6%max |

|

|

|

K2O+Na2O |

0.4%max |

|

|

|

B.D. |

3.10g/ccm min. | ||

|

Refractoriness: |

1770°< Refractoriness< 2000° | ||

Size:All sizes according to customers’requirements

Standard:Industry standards

Packaging & Delivery of Calcined Bauxite Rotary Kiln Al2O3 86%:

Packaging details:1mt big bag or according to customers’ requirements

Delivery:7-15 work days after the order is confirmed

Competitive Advantages:

High Heat-resistance.

High Purity & Good Quality.

Timely delivery & service

Good company reputation

Competitive Price & Reputable Supplier.

Usage/Applications:

1.Aluminium industry. Used in national defense, aerospace, automotive, electronics, chemical industry, daily necessities, etc.

2. Precision casting. Alumina clinker made after the mould precision casting processed into fine powder. Used in military industry, aerospace, communications, instrumentation, machinery and medical equipment department.

3.Refractory products. High bauxite clinker refractoriness is as high as 1780, chemical stability strong, and good physical properties.

4.Aluminum silicate refractory fiber. With light weight, high temperature resistance, good thermal stability, low thermal conductivity, heat capacity is small and the advantages of resistance to mechanical shock. Used in iron and steel, nonferrous metallurgy, electronics, petroleum, chemical, aerospace, atomic energy, defense and other industries.

5. In magnesia and bauxite clinker as raw materials, add the appropriate binder, used for pouring ladle whole ladle lining has particularly good effects.

6.Manufacture alumina cement, abrasive materials, ceramic industry and chemical industry can be aluminum of various compounds.

- Q: I wanna ask that magnesium oxide is refractory?

- Magnesium oxide is used in refractory material, because it has the following characteristics and properties: 1, high stability: Anti-oxidation, anti-reduction, thermal decomposition; 2, high melting point, 2800 degrees; 3, low prices. In particular, the stability and melting point is very good, I hope I can give you help.

- Q: How can refractory materials be divided?

- There are many criteria for the classification of refractories.Just referring to a book about refractory.

- Q: What's the fire?retardant material of roller shutter fire resistance door ?

- They are composited by inorganic materials, and the main components are perlite, inorganic adhesive and other special formula. It has flat and smoothe surface, unibody and stronger strength after molding. It has owned Chinese and Taiwan strength patent. It is fireproof, sound and thermal insulating. It has passed tests of Tianjin Fire Research Institute and Beijing construction institute. It is an ideal product.

- Q: what's the varieties of fire-proof?sealing?material?

- ATD-AB, organic fire-proof caulking, fire retardant bag, fire retardant net, fire retardant ring, fire barrier wrap, fireproofing sealing strip, flexibility fireproofing coiled material, fireproof glue, etc., fireproofing sealing materials currently on the market can be divided into two types, one is the traditional type: flexible organic caulking, WXY-II, fire retardant bag, fire?bulkhead, cable refractory coating; there are some new materials used in large-scale projects: fireproofing coating board system (fireproofing coating board, intumescent fireproof sealing tape, elastic fireproof sealant, Waterborne Fire-retardant Coating), fire retardant module system (fire retardant module, sealing gum, cable refractory coating), fireproofing plaster system (fireproofing plaster, sealing gum, cable refractory coating).

- Q: What are the qualifications of refractory industry?

- 1 business license 2 tax registration certificate 3 organizing institution bar code 4 production permit

- Q: What is the material composition of the new fire-resistant coating?

- The basic composition of thick coating steel structure fire is: Binder (Portland cement, magnesium oxychloride or inorganic high-temperature bonding agent), aggregate (expanded vermiculite, perlite, aluminum silicate fiber, mineral wool, rock wool, etc.), chemical additives (modifiers , hardening agent, waterproofing agent) and water. Fireproof coating binders Portland cement, magnesium oxychloride cement and an inorganic binder of the fire-resistant coating for steel structure base material. The conventional inorganic binder include alkali metal silicates and phosphates substances.

- Q: The following statement is correct: artificial corundum has a high melting point and can be used as a high grade refractory material. The main component is silica dioxide

- 1. corundum is the main component of alumina. 2. agate is the main component of silica. 3. is right. 4. glass is silicate. 5. solar cells are made from monocrystalline silicon. So 3.5 correct, choose D.

- Q: How to prolong the furnace age of Induction furnace by using fireproof materials?

- magnesia solid materials have thermal endurance and erosion/ performance and its change of temperature is likely to cause cracks. properties of materials (aluminum) in such case have to be taken into consideration.

- Q: What's the B grade fireproofing material?

- Grade B: rubber and plastic, extrusion molding, polyphenyl, PEF. organics, extruded sheet, polyphenyl board, phenolic resin. Hairong modules (thermal insulating and fireproof material) can reach grade B1 in fireproof performance.

- Q: What is shapeless refractory with high performance?

- The popular ones are: Non-cement fine powder bonded castable is a functional refractory castable with nano material introduced.

1. Manufacturer Overview

| Location | Tianjin,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;Japan;North America |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Raw Materials for Refractory:Calcined Bauxite Rotary Kiln Al2O3 86%

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Metric Ton/Metric Tons m.t.

- Supply Capability:

- 20000 Metric Ton/Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords