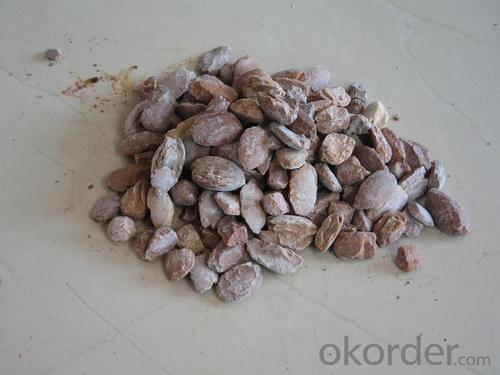

Raw Materials for Refractory:Dead Burnt Magnesite / DBM

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Dead Burnt Magnesite (DBM):

Dead Burnt Magnesite is selected from natural magnesite, calcined temperature and the shaft kiln. It is the material of ordinary magnesia bricks, shaped and unshaped refractory products.

Specifications of Dead Burnt Magnesite (DBM):

Specification(%) | ||||||

Brand |

MgO min. |

LOI max. |

SiO2 max. |

CaO max. |

Fe2O3+Al2O3 max. |

B.D.G/cm3 min. |

DBM90 |

90.00 |

1.00 |

4.50 |

2.50 |

3.00 |

3.1 |

DBM-95 |

95.00 |

0.30 |

3.00 |

2.00 |

1.30 |

3.15 |

DBM-97 |

97.00 |

0.20 |

0.7 |

1.3 |

0.90 |

3.25 |

DBM-972 |

97.2 |

0.2 |

0.6 |

1.3 |

0.9 |

3.27 |

DBM975 |

97.5 |

0.1 |

0.6 |

1.2 |

0.8 |

3.28 |

Packaging & Delivery of Dead Burnt Magnesite / DBM:

Packaging details:1mt big bag or according to customers’ requirements

Delivery:7-15 work days after the order is confirmed

Applications:

1.Mainly used in processing raw materials of different magnesia refractory,

2. the production of steel lining the bottom and ramming mixes;

3. the raw materials of magnesia brick and magnesia-chrome brick;

4.used electric steel making furnace, heating furnace, non-ferrous metals blowing converter furnace the bottom and the lining of the refractory materials.

Advantages

1.We can control the quality and cost due to our strong capacity and cash flow in China .

2. We have strict and mature quality and logistics control on the cargo .

3.As a governmental company, we are reliable.

- Q: What's the fire endurance of fire windows?

- That is fire resistance rating, fire-resistant time in the case of fire! It can be basically classified into the following levels and the fire endurance of the fire window is as follows as well: A class fire window: no less than 1.2h; B class fire window: no less than 0.9h; C class fire window: no less than 0.6h. This is in accordance with the latest specification of gb16809-2008 fire windows.

- Q: Procedures for producing common refractory materials?

- The general procedures of producing refractory materials include calcination of raw materials, selection of raw material , crushing, grinding, screening, mixing, ageing mixture, molding, drying, burning and etc. At present, the refractory factory usually purchases the calcined clinker, so the calcination of raw material is no longer a consideration of common refractory plants.

- Q: How many types do refractory bricks have? Where the quality of refractory material is best? What is the model?

- Sinosteel Luoyang (Luoyang Refractory Material Plant in the past): High alumina(mainly blast furnace), Gongyi. There are also a series of high-tech materials (silicon carbide, carborundum, etc.) a major producer of high alumina; silicious: Resistant material for steel, glass furnace, cement kiln); magnesia. Divide from uses and divide from chemical texture; silicious(glass furnace): Xinmi, Hennan Province, Lengshui River, coke oven, etc.). As for the models, Yixing and Changxing in Jiangsu Province: Haicheng, Liaoning Province; silicious, I do not understand your intentions; magnesia (nonferrous, steel refining; magnesia: High alumina brick; Dashiqiao area! Please put it in detail.

- Q: Who knows about the criteria of fireproof and thermal insulation materials?

- Seven levels are divided according to "The classification of combustion performance of building materials and products", namely, A1, A2, B, C, D, E, F. It mainly refers to the combustion performance of materials. You can check on this standard for the specific dividing evidence. There are detail charts which mainly describe that whether there is drip or not, the ignition time, continuous burning time and so on.

- Q: Which refractory material is better in China? Industrial furnace, mainly in non-ferrous industries, glass kiln, cement kiln business.

- Such solid nano microporous insulation material with nano inorganic refractory powder special, with a huge surface area, nano particles contact between the minimum point contact point contact thermal resistance is very large, the heat conduction effect of the material becomes very small, resulting in heat conduction coefficient of solid such nano porous insulation materials very small; nano pores formed of nanoparticles, the average size of 20 nm, and the average free path of molecular thermal motion at room temperature under static air is 60 nm, thus locking the air molecules in powder within nano pores, making the micro convection heat transfer effect between the stationary air molecules disappeared. The room temperature thermal conductivity of solid such nano microporous insulation material is lower than the static air; at high temperature, the main effect of heat transfer heat radiation, Good energy-saving insulation materials with nano microporous infrared additive special, stop at a high temperature and reflected infrared radiation, reduce the heat radiation effect to the lowest point, the radiation heat transfer coefficient of materials under high temperature is reduced to the lowest value.

- Q: The difference between refractory and thermal insulation material

- In simple terms, refractoriness is different. The refractoriness of refractory is high while that of insulation material is low.

- Q: What thickness is needed of the ultra-thin fireproof paint with a fireproof time of 2.5 hours?

- The thickness of steel structure fire retardant coating hasn't been regulated in the steel structure application specification (CECS24:90). The above thickness refers to a certain thickness that must (at least) achieve a certain time of the fire resistance. The thickness of fire-retardant coating in engineering is generally determined according to factory inspection report. We use thin steel structure fire retardant coating: 2.5 hours' fire resistance with the thickness of 4.9 mm; 2.0 hours' fire resistance with the thickness of 3.5 mm; 1.5 hours' fire resistance with the thickness of 1.75 mm; 1.0 hours' fire resistance with thickness of 1.17 mm. I hope I can help you.

- Q: What are the types of steel refractory materials

- The major category is classified as permanent layer, working lining. Specific varieties: Air permeable brick (corundum). steel ladle brick (magnesia or corundum), permanent layer castable (high alumina), reinforcing material for ladle bottom, repair material for the edge of tank and so on.

- Q: What's the A grade fireproofing material?

- A grade fireproofing material: 1. fire-proof plate; 2. fireproof wooden door; 3. fireproof wooden window frame; 4. fire resisting shutter; 5. fireproof and mothproof wood; 6. fireproof glove compartment; 8. fire?retardant?coating; 9. fire-proof?sealing?material.

- Q: What's the fire endurance of A grade fireproof glass curtain wall?

- The following is fire endurance of A class fireproof glass curtain wall. Fire endurance of the fire window: A class fire window: no less than 1.2h; B class fire window: no less than 0.9h; C class fire window: no less than 0.6h. Technical requirements: 1. Materials and fittings: (1) Window frame should adopt the steel frame or wood frame with certain strength so as to guarantee the integrality and stability of the fitting; (2) Steel frame and mound layer can choose the galvanized steel sheet or stainless steel sheet. Its selection standard is in line with provisions of Article 5.1 in GB12955 "General Technical Requirements on Steel Fire Doors"; (3) Selection standard of wood frame and mound layer should be consistent with the provisions of Article 5.1.1 in GB14101 "General Technical Requirements on Wood Fire Doors"; (4) Filler material inside the steel frame and wood frame should be incombustible material; (5) Fireproof glass can choose the qualified product with no influence on the fire resistance test of the fire window, and its light transmittance should be no less than 75% of that of the ordinary sheet glass with the same layers; (6) Sealing material between the frame and the fireproof glass should use flame retardant material which can play the role of fire prevention and smoke insulation in case of fire. Hope it's helpful for you.

1. Manufacturer Overview

| Location | Tianjin,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;Japan;North America |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Raw Materials for Refractory:Dead Burnt Magnesite / DBM

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords