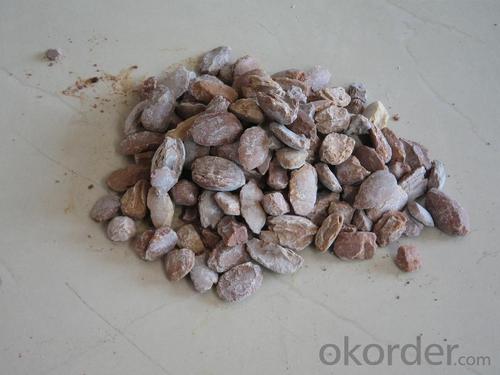

Raw Materials for Refractory:Dead Burnt Magnesite with Good Quality and Good Price (DBM)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Dead Burnt Magnesite DBM

Main products level

0-1mm

1-3mm

3-5mm

0-10mm

200mesh (90% through)

325mesh

Specification

Grade | MgO (min.) | SiO2 (max.) | CaO (max.) | Fe2O3 (max.) | Al2O3 (max.) | L.O.I. (typical) |

mesh |

DBM90 | 90.00% | 1.00% | 1.50% | 0.70% | 0.10% | 1.70% |

0-400 |

DBM95 | 95.00% | 1.00% | 1.50% | 0.80% | 0.10% | 2.60% | |

DBM96 | 96.00% | 1.50% | 2.50% | 0.80% | 0.30% | 2.90% | |

DBM97 | 97.00% | 3.00% | 2.50% | 0.80% | 0.30% | 3.40% |

Usage

Mainly used in producing common magnesite brick, magnesite aluminum brick, magnesite chrome brick, gunning mix, hot patching mix for converter and EAF ect.

Features

Our factory produce the products of the Dead-burned magnesite are selected natural magnesite, it is produced by mine-selecting, purifying, calcimine in shaft kiln. It is an ideal material for unshaped refractory material, the final products are used in open hearth furnace, electric furnace bottom and furnace's lining tamping.

- Q: What are unshaped fire-resisitance materials?

- Refractory castable, refractory plastic material, usually classified according to construction and manufacture method, unfired bricks precast block, refractory pressed into material, refractory cast material, refractory coating, refractory ramming material there are many classification methods

- Q: What is acid refractory material?

- Corundum products containing more than 95% of alumina are a kind of high quality refractory materials with a wide range of uses. Chrome brick by using chromium oxide as the main component of the corrosion resistance of steel slag is good, but the poor heat shock resistance, high load low deformation temperature. Carbon refractories with carbon bricks, graphite and silicon carbide products, low coefficient of thermal expansion, high thermal conductivity, heat vibration performance, high strength, corrosion resistance to acid and salt, without wetting of the metal and slag, light. It is widely used as lining material of high temperature, and also used as lining of autoclave in petroleum and chemical industry. Basic refractories in Magnesium Oxide and calcium oxide as the main ingredient, commonly used is brick. Magnesium Oxide 80% to more than 85% containing magnesia brick, has good resistance to alkaline slag and slag, refractory clay brick and brick high ratio. Mainly used in open hearth furnace, oxygen converter, electric furnace, non-ferrous metal smelting equipment and high temperature equipment. High temperature oxide materials in refractory special applications, such as aluminum oxide, lanthanum oxide, beryllium oxide, calcium oxide, zirconium oxide, refractory compounds, such as carbides, nitrides, borides, silicides and sulfides; high temperature composite materials, including metal ceramics, high temperature inorganic coatings and fiber reinforced ceramics.

- Q: What is the principal part of silicious refractory material

- Shenzhen Longgang Jiangyou Hua Boiler Accessories Co., Ltd. is specialized in refractory cement, refractory mortar, refractory clay, refractory aggregate and perlite. And other refractory | thermal insulation material, it has cooperated projects in Shenzhen, Huizhou, Dongguan, Guangzhou, Foshan, Zhuhai and other sites. For more information you can find our website on Baidu.

- Q: I want to consult the fire resistant level standards of external wall thermal insulation materials.

- Fire resistant level standards of external wall thermal insulation materials: 1, The thermal insulation material that has A-class combustion performance: Spraying inorganic fiber, glass wool, foam glass, ceramic foam, rock wool, foam cement and perlite obturator, and so on. 2, The thermal insulation material that has B1 level combustion performance: Special processed extruded polystyrene board (XPS) / special processed polyurethane (PU), phenolic and polystyrene powder. 3, Thermal insulation materials that have level B2 combustion performance: Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc.

- Q: who knows the requirements of refractory for forge furnace?

- Forging heating furnace working temperatures above 1000 ° C, reasonably choosing refractory for build furnace has an important meaning for guaranteeing the normal operation of the heating furnace, improving the service life of furnace and energy saving. refractory is generally required to have the following properities: 1, it should be equipped with the properity of no deformation and melting under certain temperature. 2, it should be equipped with the neccessary structural strength without softening deformation in high temperature. 3, volume stability at high temperature, brick body won't be deformation or cracked due to expansion and contraction; 4, not broken and peel off under rapid changes of temperature or uneven heating; 5, resistant to chemical erosion of molten metal, slag and furnace gas,etc.

- Q: Does anyone know what is a lightweight refractory material?

- The volume shrinkage is larger, and the corrosion resistance is higher at high temperature. A lightweight refractory material, used as thermal insulation material in industrial furnace and other thermal equipment, has poor wear resistance, weak mechanical strength and small volume density. Compared with ordinary refractory bricks, the lightweight refractory with low thermal conductivity has higher porosity.

- Q: Why should graphitic refractory materials be used now that graphite can burn?

- C is inactive in nature. Carbon will not burn unless the temperature is about 2000℃, so it can't be lit generally. Coal can be lit because it contains other combustible substance which ignite carbon indirectly. While graphite, carbon black, is more pure and dense than coal., so it is hard to oxidize.Their molecular structures are also different, just like diamond is harder than graphite.

- Q: What is shapeless refractory with high performance?

- The popular ones are: Non-cement fine powder bonded castable is a functional refractory castable with nano material introduced.

- Q: The manufacturing technique of refractory material

- The major components of alkaline refractory material include magnesium oxide and calcium oxide. The commonly used alkaline refractory material is magnesia bricks. The magnesia bricks with 80%~85% magnesium oxide has good resistance to basic slag and slag and higher refractoriness than clay bricks and silica bricks. It is mainly used in open hearth, oxygen blowing of converter, electric furnace and smelting non-ferrous metal equipment and other high temperature equipment. Refractory materials applied on special occasions include high temperature oxide refractory materials such as alumina, lanthanum oxide, beryllium oxide, calcium oxide, zirconium oxide, etc., refractory compounds such as carbide, nitride, boride, silicide and sulfide, etc., and high temperature composite materials, including metal ceramics, high temperature inorganic coating and fiber reinforced ceramics, etc. Consult and find reference for efractory materials production equipment, go to http://hi.baidu.

- Q: What 's the highest temperature can magnesium plate glass resist ?

- Glass magnesium plate is non combustible plate having good fire-resisitance quality. Flame will never burn continuously on it. It does not catch on fire when temperature reach 800 ℃, and will not be lit up at 1200 ℃. The plate, having high-quality keel partition system, is rated as the highest non-combustible level A1 with fire resistance being above 3 hours. It absorbs a lot of heat when fire is burning, delaying rise of ambient temperature.

Send your message to us

Raw Materials for Refractory:Dead Burnt Magnesite with Good Quality and Good Price (DBM)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords