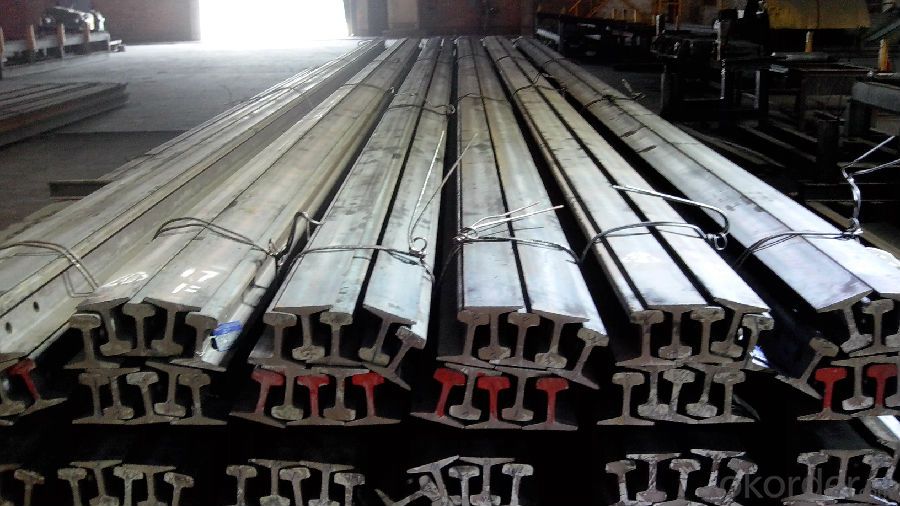

Railroad Steel Rail in High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Railroad Steel Rail in High Quality at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Railroad Steel Rail in High Quality are ideal for structural applications and are widely used in forest region, Mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.etc.

Product Advantages:

OKorder's Railroad Steel Rail in High Quality are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q235, 55Q

Certificates: ISO, SGS, BV, CIQ

Length:6m, 12m,12.5m

Package: Packed in bundles and shipped by break bulk or containers.

LIGHT RAIL/HEAVY RAIL | Height (mm) | Bottom (mm) | Head width (mm) | Head height (mm) | Waist height | Bottom height (mm) | Waist thichness (mm) | Section cm2 | Mass: Kg/m |

9 | 63.50 | 63.50 | 32.10 | 17.48 | 35.72 | 10.30 | 5.90 | 11.30 | 8.94 |

12 | 69.85 | 69.85 | 38.10 | 19.85 | 37.70 | 12.30 | 7.54 | 15.54 | 12.2 |

15 | 79.37 | 79.37 | 42.86 | 22.22 | 43.65 | 13.50 | 8.33 | 19.33 | 15.2 |

22 | 93.66 | 93.66 | 50.80 | 26.99 | 50.00 | 16.67 | 10.72 | 28.39 | 22.3 |

30 | 107.95 | 107.95 | 60.33 | 30.95 | 57.55 | 19.45 | 12.30 | 38.32 | 30.1 |

FAQ:

Q1: How many tons of steel products could be loaded in containers?

A1: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Q2: what is the difference between actual weight and theoretical weight?

A2: All the section steel has two weights: actual weight and theoretical weight. Actual weight is the weighing out when the product delivered from the mill. Theoretical weight is calculated by pieces. The invoice can be based on each of them as your request.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: How do steel rails contribute to reducing the risk of wheel climb and flange climb?

- Steel rails contribute to reducing the risk of wheel climb and flange climb by providing a smooth and stable surface for train wheels to run on. The high strength and durability of steel rails ensure that they remain intact under heavy loads, preventing any sudden deviations or movements that could lead to wheel or flange climb. Additionally, steel rails are designed with specific profiles and dimensions to guide the wheels and keep them on track, minimizing the chances of climbing.

- Q: How much weight can steel rails support?

- The weight that steel rails can support depends on various factors such as the specific type and grade of steel, the dimensions and design of the rail, the support structure, and the conditions of the environment. Generally, steel rails can support significant loads ranging from several tons to even hundreds of tons, enabling the smooth operation of heavy locomotives and trains.

- Q: How do steel rails handle different types of loads (e.g., freight, passenger)?

- Steel rails are designed to handle different types of loads, including both freight and passenger trains. The strength and durability of steel rails make them capable of withstanding heavy loads and repeated impacts. The weight distribution and wheel configuration of trains are carefully considered to ensure even load distribution on the rails. Additionally, steel rails are designed to handle the dynamic forces exerted by different types of trains, such as the higher speeds of passenger trains and the heavier weights of freight trains. Overall, steel rails provide a sturdy and reliable infrastructure for the safe and efficient transportation of both freight and passenger traffic.

- Q: What is the weight of steel rails per yard?

- The weight of steel rails per yard can vary depending on the specific type and size of the rail. On average, standard steel rails can weigh around 100 pounds per yard.

- Q: Can steel rails be used in mining railways?

- Yes, steel rails can be used in mining railways. In fact, steel rails are commonly used in mining operations due to their strength and durability. Mining railways often need to withstand heavy loads and harsh conditions, and steel rails provide the necessary support and stability. Additionally, steel rails can be easily maintained and repaired, ensuring the smooth and efficient transportation of materials in mining operations. Overall, steel rails are a reliable and cost-effective choice for mining railways.

- Q: How are steel rails joined together?

- Steel rails are typically joined together using a process called rail welding, which involves heating the ends of two rails and then pressing them together to create a strong, continuous joint.

- Q: What are the different types of steel rail profiles?

- There are several different types of steel rail profiles, including but not limited to, flat-bottomed rails, bullhead rails, vignole rails, and double-headed rails. Each profile is designed for specific applications and has unique features and characteristics that make them suitable for different types of rail systems.

- Q: What is the role of rail clips in steel rail installation?

- Rail clips play a crucial role in steel rail installation by securing the rail to the baseplate, ensuring proper alignment and stability of the track. They help distribute the forces exerted on the rail, preventing it from shifting or moving under the weight of passing trains. Additionally, rail clips help absorb vibrations and reduce noise, enhancing the overall performance and longevity of the railway system.

- Q: How are steel rails affected by dynamic loads?

- Steel rails are affected by dynamic loads in several ways. First, the repeated impact from moving trains can result in fatigue, leading to cracks and fractures in the rail. Second, the dynamic loads can cause deformation and bending of the rail, which can affect its alignment and stability. Finally, the vibrations generated by dynamic loads can weaken the rail's structural integrity over time. Therefore, proper maintenance and inspection are essential to ensure the safety and durability of steel rails under dynamic loads.

- Q: How do steel rails contribute to the stability of train tracks?

- Steel rails contribute to the stability of train tracks by providing a strong and durable foundation for the train wheels to ride on. The steel rails help distribute the weight of the train evenly, preventing excessive wear and tear on the tracks. Additionally, the smooth surface of the rails reduces friction, allowing the train to move more efficiently and safely.

Send your message to us

Railroad Steel Rail in High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords