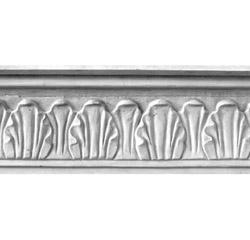

Qualified Eaves Decorative Rid Mould

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Sets set

- Supply Capability:

- 30000000 Sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Qualified Eaves Decorative Rid Mould-1:

It is made by the special GRG high-strength powder mixing with the high-strength alkali-free fiberglass and reinforcer. To increase the strength of the structures, we will embed wooden timbering, galvanized keel, fiberglass rob, fiberglass mesh cloth. The products are featured by high strength, good flexibility and good resistance to impact. So it is widely used in senior clubs, five-star hotels, luxury villas, modernization office building.

Specifications of Qualified Eaves Decorative Rid Mould-1:

We can offer Mould for Eaves Decorative Rid products, size: (L)1200mm*(H)240mm, (L)1800mm*(H)500mm, etc. Other sizes can be customized according to customer requirements.

- Q: i need info about that and also about somethings that can reduce the emissions of CO2 in the atmosphere?? if you tell me the page you will rock=D

- cement is neither good nor bad in the environment making it gives off C02, using it takes the C02 Back CaCo3 + heat= CaO + C02 (cement) CaO + H20 + C02 = CaC03 (concrete) Planting lots of trees takes C02 out of the atmosphere

- Q: please help...

- IT IS VERY HARM FULL

- Q: How is cement made and what is in it?

- It's actually kind of a complicated chemical process, where certain mineral compounds are crushed into a powder and, when you add water and mix it, this causes the mineral compounds to slightly change their chemistry such that they bond together into a hard rock-like substance. This process is called curing (concrete doesn't actually dry to become hard - the concrete cures, like epoxy). And, the exact minerals that are used can vary. Concrete is cement with some kind of mineral aggregate mixed in with it. This could be sand, coarser gravel, or even larger river rock pebbles. Reinforced concrete is where they lay out some kind of steel framework structure in the concrete mold prior to pouring the concrete. This could be sheets of steel mesh, lengths of rebar wired together, or both.

- Q: the house is from 1959. Before I bought it the owners re-landscaped without any consideration for water flow thus causing the basement to have seepage through the walls. I fixed the water flow issue (1.5 years dry) but now I have painted cement walls that have paint pushed out/peeling with a few visible cracks and wonderful mineral deposition. I really don't want to spend the time with the metal wire brush to strip the paint off so I would like to just use hydraulic cement over the whole wall and then use a water sealing paint over the top. Is this a good idea? other suggestions?

- That sounds more time consuming than just scraping off the peeling paint..... Here's 1 problem w/your approach, latex paint dries so fast that it actually creates a vacuum effect in doing so, which means that as it dries it'll pull off the surface anything that's not firmly attached, which is why prep work's so important to longevity. You won't immediately notice this happening, but w/the passage of time you'll be back to the peeling wall in spades. I've never heard of skim-coating w/hydraulic cement, but I've done plenty of patching plaster walls w/plaster of paris, what immediately comes to mind are the inherent problems w/working in a medium that sets up so quickly, I can't imagine how you'd get a whole wall covered looking even satisfactory (but I'm pretty picky, I figure when people are paying me I'm obliged to do a better job than they could've) w/out going insane in the process. I learned the trick to plaster, but I don't know the chemistry of hydraulic cement well enough to find a retardant for it. Anyways, I know prep-work sucks, but often it's just easiest to do it get it over with (start w/a stiff putty knife, by the way) rather than inventing a new process having to deal w/a long string of learning curves as you go. The first question that came to mind w/your question is have you ever skim-coated anything before so that you'd have even a vague idea of what you're getting yourself into potentially, but if you must create, than by all means go forth!

- Q: Is there a big difference in strength when gluing PVC pipe?

- As far as the strength factor, epoxy would provide adequate strength to the PVC joint. However, there are some fine points you should be aware of. First, epoxy tightly bonds two pieces together through itself. Epoxy's strength is due to the strength of the cement itself. PVC cement on the other hand, dissolves the surface of the PVC pipe, bonding the PVC sections tightly together when the cement dries. It's as if the two pieces were welded together. Second, PVC cement is approved for potable water supplies. Epoxy is not. Finally, the setting time for epoxy is measured in hours. It's measured in seconds for PVC cement. The PVC cement bonded sections will be ready for service much faster than if you bonded them with epoxy. That's why plumbers use it instead of epoxy.

- Q: why is cement still very high when everything is going down?

- It's all about C's : Cartel, Corruption, Conspiracy

- Q: Quartz Arenite, Shale, Carbonatite, Greywacke, Limestone, Arkose, Altered Granite or Rhyolite?

- Limestone is used in Portland cement. Powdered clay is mixed with powdered limestone and heated in a revolving kiln. This produces cement which is then combined with water, crushed rock and sand before pouring.

- Q: How a cement solution is prepared;;what is effect of quick setting of cement;;?

- cement is an ingredient in concrete. It sets with the chemical reaction of Calcium carbonate (limestone) and water to form a hard substance.

- Q: I am looking forward to building a block fence. I ran into a YouTube video on the Quikwall surface bonding cement and was curious on your thoughts about that product. Have you tried it? On what and what do you think about it? Thanks!

- This Site Might Help You. RE: Your thoughts on Quikwall surface bonding cement.? I am looking forward to building a block fence. I ran into a YouTube video on the Quikwall surface bonding cement and was curious on your thoughts about that product. Have you tried it? On what and what do you think about it? Thanks!

- Q: Poll: Rubber cement or School glue?

- Definitely rubber cement. It smells better and is much cooler. I love how it stays flexible and allows you to remove excess or misapplied rubber cement easily.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2000 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Lianyungang PORT |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 26,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Qualified Eaves Decorative Rid Mould

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Sets set

- Supply Capability:

- 30000000 Sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords