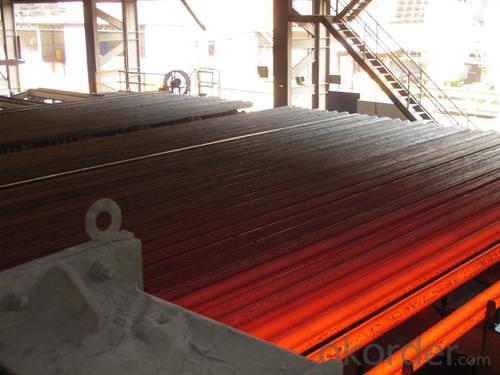

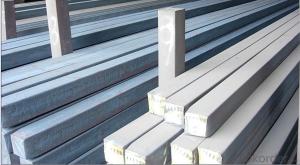

Prime Q275 80mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime Q275 80mm Square Alloy Steel Billet

Description of Prime Q275 80mm Square Alloy Steel Billet

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime Q275 80mm Square Alloy Steel Billet

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime Q275 80mm Square Alloy Steel Billet

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime Q275 80mm Square Alloy Steel Billet

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime Q275 80mm Square Alloy Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel billets measured and classified?

- The dimensions and chemical composition of steel billets are used to measure and classify them. Typically, the length, width, and height of a steel billet are measured to determine its size and shape, which impacts its usability in various applications. Moreover, the chemical composition of steel billets is examined to classify them. This involves analyzing the percentage of elements like carbon, manganese, silicon, and sulfur in the steel. The chemical composition is crucial for determining the mechanical properties of the billet, including tensile strength, hardness, and ductility. International standards, established by organizations such as ASTM or ISO, are usually followed for the classification of steel billets. These standards ensure consistency and quality in the measurement and classification processes across the industry. To obtain accurate dimensions, steel billets are commonly measured using calipers or precision measuring instruments. The length is measured from one end to the other, while the width and height are measured at their widest points. The measurements are often recorded in millimeters or inches, depending on the regional standards. Once the dimensions and chemical composition are determined, steel billets are classified into different grades or specifications. These classifications help identify the suitable applications and industries for the billets. For instance, specific grades may be suitable for construction purposes, while others are more suitable for manufacturing automotive parts or machinery. In summary, steel billets are measured and classified based on their dimensions and chemical composition. The dimensions are measured in terms of length, width, and height, while the chemical composition is analyzed to determine the percentage of various elements. These measurements and classifications are crucial in determining the usability and quality of steel billets in different applications and industries.

- Q: What are the main differences between hot rolled and cold rolled steel billets?

- The manufacturing process and resulting properties of the finished product are where the main distinctions between hot rolled and cold rolled steel billets lie. Hot rolled steel billets are created by subjecting the steel to high temperatures and passing it through large rollers. This method allows for easy shaping and forming of the steel, resulting in a rougher surface and less precise dimensions. Additionally, the high temperature involved in the manufacturing process leads to a scaled surface on hot rolled steel billets. In contrast, cold rolled steel billets are produced by cooling the steel to room temperature and passing it through rollers at a lower temperature. This process yields a smoother surface finish and allows for tighter tolerances and more precise dimensions. Cold rolled steel billets have a more uniform appearance and are commonly utilized in applications that require high levels of precision and accuracy. When it comes to mechanical properties, hot rolled steel billets generally exhibit lower strength and hardness compared to cold rolled steel billets. Cold rolled steel billets also tend to possess improved surface hardness and a higher degree of dimensional stability. In conclusion, the main distinctions between hot rolled and cold rolled steel billets encompass the manufacturing process, surface finish, dimensional accuracy, and mechanical properties. Hot rolled steel billets are easily shaped and formed, while cold rolled steel billets possess a smoother surface finish and more precise dimensions. The choice between the two depends on the specific requirements of the application.

- Q: How is the quality of steel billets determined?

- The quality of steel billets is determined through various factors including chemical composition, physical properties, and visual inspection. Chemical composition analysis involves measuring the levels of different elements present in the billets such as carbon, manganese, and sulfur, as well as checking for any impurities. Physical properties such as tensile strength, hardness, and toughness are tested to ensure the billets meet the required specifications. Visual inspection is also performed to identify any defects like cracks, surface abnormalities, or unevenness. Combining these assessments helps determine the overall quality of steel billets.

- Q: What is the typical impact strength of a steel billet?

- The typical impact strength of a steel billet varies depending on the specific grade and composition of the steel. In general, steel billets exhibit a high level of toughness and can withstand significant impact forces without fracturing or breaking. This is due to the inherent strength and ductility of steel as a material. However, it is important to note that the impact strength of a steel billet can be further enhanced through various processes such as heat treatment or alloying. These processes can help improve the material's resistance to impact, making it even more durable and suitable for demanding applications. Ultimately, it is crucial to consider the specific grade and composition of the steel billet in order to determine its exact impact strength. Different steel grades are designed for different purposes, and their impact strength can vary accordingly. Therefore, it is recommended to consult the manufacturer or refer to the material specifications to obtain accurate and detailed information regarding the typical impact strength of a particular steel billet.

- Q: What are the main surface finishes available for steel billets?

- The main surface finishes available for steel billets include mill finish, pickled and oiled (P&O), galvanized, painted, and coated finishes. Mill finish refers to the surface of the steel billet as it comes from the rolling mill, which is typically characterized by a rough and unfinished appearance. This finish is suitable for applications where aesthetics are not a priority, such as when the billets will be further processed or coated. Pickled and oiled (P&O) finish involves treating the steel billets with an acid solution to remove any mill scale or impurities, followed by applying a thin layer of oil to protect the surface from oxidation. This finish provides a clean and smooth surface, making it suitable for applications where a high-quality appearance is desired. Galvanized finish involves immersing the steel billets in a zinc bath to create a protective layer of zinc coating over the surface. This finish provides excellent corrosion resistance, making it ideal for outdoor applications or environments with high moisture or chemical exposure. Painted finish involves applying a layer of paint onto the surface of the steel billets. This finish offers both aesthetic appeal and protection against corrosion, as the paint acts as a barrier between the steel and the external environment. Painted finishes can be customized in terms of color and texture to suit specific requirements. Coated finishes involve applying a specialized coating onto the surface of the steel billets. These coatings can include epoxy, polyurethane, or other protective materials that provide enhanced corrosion resistance, chemical resistance, or heat resistance. Coated finishes are often used in industries such as automotive, construction, or oil and gas, where the billets are subjected to harsh conditions. Overall, the choice of surface finish for steel billets depends on the specific application requirements, including aesthetics, corrosion resistance, durability, and environmental factors.

- Q: What are the different types of steel billet heat treatment processes?

- There are several types of steel billet heat treatment processes, including annealing, normalizing, quenching, and tempering. Annealing involves heating the billet to a high temperature and then slowly cooling it to relieve internal stresses and improve its ductility. Normalizing is similar to annealing but involves cooling the billet in still air to achieve a more uniform grain structure. Quenching is a rapid cooling process that involves immersing the billet in a quenching medium, such as water or oil, to achieve high hardness and strength. Tempering follows quenching and involves reheating the billet to a lower temperature to reduce brittleness and enhance toughness.

- Q: How do steel billets contribute to the manufacturing of agricultural equipment?

- Steel billets are a crucial component in the manufacturing of agricultural equipment due to their versatility and durability. These billets, which are essentially semi-finished steel products, serve as the foundation for various agricultural machinery and equipment. Firstly, steel billets are used to create the main structural components of agricultural equipment such as tractors, harvesters, plows, and tillers. These components, such as the chassis, frame, and axles, require a strong and sturdy material to withstand the heavy loads and harsh conditions encountered in agricultural operations. Steel billets provide the necessary strength and resilience to ensure the equipment can withstand the rigors of farming. In addition to the structural components, steel billets are also used to manufacture smaller parts and mechanisms that are integral to the functioning of agricultural machinery. For example, gears, sprockets, shafts, and bearings are commonly made from steel billets. These parts are essential for transmitting power and facilitating the smooth operation of various agricultural equipment. Moreover, steel billets contribute to the longevity and reliability of agricultural equipment. The high strength and durability of steel ensure that the machinery can withstand the demanding agricultural environment, including exposure to moisture, dirt, and extreme temperatures. This durability reduces maintenance requirements and extends the lifespan of the equipment, resulting in cost savings for farmers. Furthermore, steel billets can be easily shaped and molded into complex designs, allowing manufacturers to create customized agricultural equipment tailored to specific farming needs. This flexibility in design enables the production of specialized machinery for various agricultural operations, such as planting, harvesting, irrigation, and livestock management. Overall, steel billets play a vital role in the manufacturing of agricultural equipment by providing the necessary strength, durability, and versatility required for the demanding conditions of modern farming. Their contribution ensures that farmers have access to reliable and efficient machinery, ultimately increasing productivity and supporting sustainable agricultural practices.

- Q: How are steel billets used in the manufacturing of electrical transmission equipment?

- Steel billets are often used as raw material in the manufacturing of electrical transmission equipment. They are typically forged or machined to create various components such as brackets, supports, and housings. These billets provide the necessary strength, durability, and dimensional stability required for the equipment to withstand high electrical loads and harsh operating conditions.

- Q: How do steel billets contribute to the manufacturing of telecommunications equipment?

- The manufacturing of telecommunications equipment heavily relies on steel billets as they supply the essential raw material for various components and structures. These billets, typically composed of carbon steel, act as semi-finished products that undergo further processing to achieve specific shapes and sizes required for telecommunications equipment. A significant contribution of steel billets to the manufacturing of telecommunications equipment is their role as the base material for constructing towers and masts. These structures are crucial for antenna and satellite dish installation, facilitating the transmission and reception of signals within telecommunications networks. Steel billets are shaped and welded to create robust and long-lasting towers capable of withstanding diverse environmental conditions. Furthermore, steel billets find application in the production of enclosures and cabinets housing telecommunication equipment. These enclosures safeguard the equipment against external factors like dust, moisture, and vandalism, ensuring optimal functioning and longevity. Steel billets are transformed into panels, frames, and chassis, which are then assembled to form resilient enclosures capable of enduring harsh environments. Moreover, steel billets contribute to the manufacturing of telecommunications equipment by being employed in the production of cable trays and supports. These components are essential for organizing and routing cables, providing an efficient infrastructure for telecommunications systems. Steel billets are rolled and shaped into various forms, such as channels and angles, to produce sturdy cable trays and supports capable of withstanding the weight and stress of multiple cables. Additionally, steel billets are utilized in the fabrication of connectors and brackets for telecommunications equipment. These small yet vital components establish necessary connections and provide support for different devices and modules within telecommunications systems. Steel billets are subjected to machining, drilling, and shaping processes to create reliable connectors and brackets, ensuring proper functionality and stability. In conclusion, steel billets have an indispensable role in the manufacturing of telecommunications equipment due to their provision of essential raw material for various components and structures. Their strength, durability, and versatility make them an ideal choice for creating robust and reliable equipment capable of meeting the demands of modern communication networks.

- Q: How are steel billets used in the production of aerospace parts?

- Steel billets are an essential component in the production of aerospace parts. These billets, which are typically made from high-quality steel, serve as the raw material from which various aerospace components are manufactured. The first step in using steel billets in aerospace part production involves their transformation into the desired shape and size. This is achieved through a process called forging, where the billet is heated to a specific temperature and then shaped using mechanical force. This allows the billet to be molded into intricate shapes and structures that are required for aerospace applications. Once the steel billet has been forged into the desired form, it undergoes a series of machining processes. These processes involve cutting, drilling, and milling the billet to achieve precise dimensions and surface finishes. Machining is crucial in aerospace part production as it ensures that the final components meet the strict tolerances and specifications required for safe and efficient performance in aircraft. Furthermore, steel billets are often used in the production of critical aerospace parts such as engine components, landing gear, and structural elements. These parts are subjected to extreme conditions, including high temperatures, vibrations, and stress. Therefore, the use of steel billets in their production is crucial to ensure their durability, strength, and resistance to wear and tear. Moreover, steel billets are often chosen for aerospace applications due to their excellent mechanical properties, including high tensile strength, toughness, and corrosion resistance. These properties make steel billets suitable for withstanding the demanding conditions experienced by aircraft during flight and ensure the long-term reliability of aerospace parts. In conclusion, steel billets play a vital role in the production of aerospace parts. Through forging and machining processes, they are transformed into the desired shapes and dimensions required for various applications. The use of steel billets ensures the durability, strength, and performance of critical aerospace components, making them indispensable in the aerospace industry.

Send your message to us

Prime Q275 80mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords