Prepainted GI steel Coil/ PPGI / PPGL/ Color Coated Galvanized Steel Sheet in Coi/PPGI/SGCC/SGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Prepainted GI steel Coil/ PPGI / PPGL /Color Coated Galvanized Steel Sheet in Coil

1. Application of Prepainted GI steel Coil/ PPGI / PPGL/ Color Coated Galvanized Steel Sheet in Coil:

Construction, the manufacturing of cars, ships,containers and household electric appliances, other industries usage

they are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commerce, etc industries.

.Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils, etc

.Corrosion resistant parts of cars

.Food storage, meat and aquatic products’ freezing and processing equipment etc;

.The equipments to store and transport materials, and packing implements.

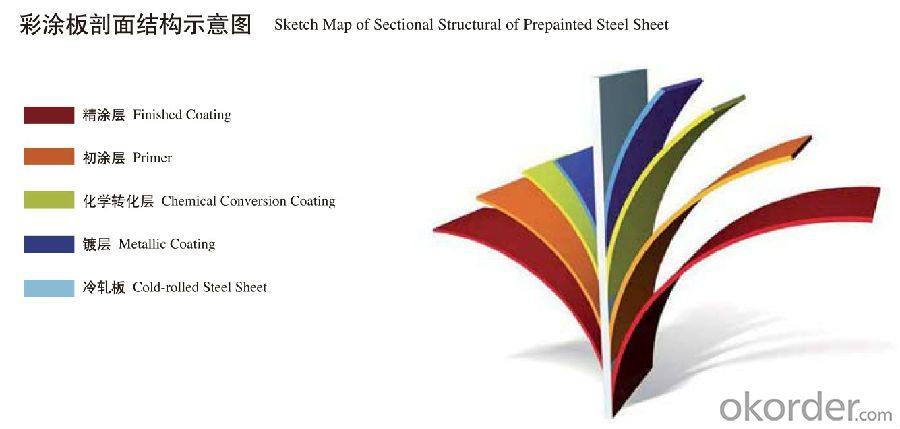

2.Features of Prepainted GI steel Coil/ PPGI / PPGL Color Coated Galvanized Steel Sheet in Coil:

* uses hot dip galvanized steel sheet as the base material

* zinc layer protection, dope on the zinc layer can cover and protect the

steel base from corrosion

* color coated sheet is light, beautiful and has good anti-erosion performancevanized steel coil

* As a rich experience manufacturer, we provide quality product, competitive price and reliable after-sales service.

3.Surface Finish of Prepainted GI steel Coil/ PPGI / PPGL/ Color Coated Galvanized Steel Sheet in Coil:

Surface finish | Pattern | Application |

Regular spangle | Standard spangles with flower pattern | General uses |

Small spanlge | Small spangles than regular | General painting applications |

Zero spangle | Extremely minimized spangles | Special painting applications |

4. Prepainted GI steel Coil/ PPGI / PPGL /Color Coated Galvanized Steel Sheet in Coil image:

APPLICATION:

PROUDUCTION LINE:

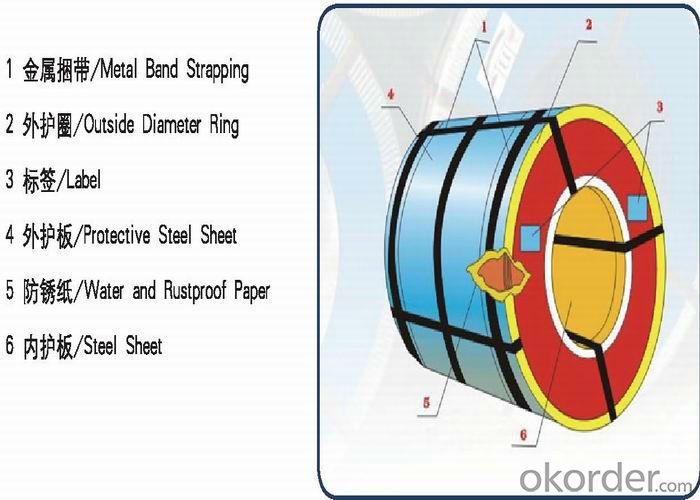

PACKING:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: How are steel coils used in the production of metal containers?

- Steel coils are used in the production of metal containers by being processed and formed into sheets, which are then shaped and welded to create the body and lids of the containers. The strength and durability of steel make it an ideal material for these containers, providing protection for goods during transportation and storage.

- Q: What are the common standards and specifications for steel coils?

- In the industry, there are various widely recognized and utilized standards and specifications for steel coils. Some notable ones include: 1. ASTM A36/A36M: This specification is concerned with carbon structural steel shapes, plates, and bars of structural quality. It is intended for use in constructions that involve riveting, bolting, or welding. 2. ASTM A572/A572M: This specification focuses on high-strength low-alloy columbium-vanadium structural steel shapes, plates, sheet piling, and bars. It is applicable for constructions involving bolting, riveting, or welding. 3. ASTM A653/A653M: This specification pertains to steel sheet that is zinc-coated (galvanized) or zinc-iron alloy-coated (galvannealed) through the hot-dip process. 4. ASTM A1011/A1011M: This specification covers various types of steel sheet and strip in coils, such as hot-rolled, carbon, structural, high-strength low-alloy, high-strength low-alloy with improved formability, and ultra-high strength. 5. JIS G3302: This Japanese Industrial Standard specifies the requirements for hot-dip zinc-coated steel sheet, also known as galvanized steel sheet, and strip. 6. EN 10111: This European standard outlines the requirements for continuously hot-rolled low carbon steel sheet and strip that are suitable for cold forming. 7. ISO 3575: This International Organization for Standardization standard lays down the requirements for hot-dip zinc-coated and zinc-iron alloy-coated steel sheet and strip. These are just a few instances of the prevalent standards and specifications employed for steel coils. It is crucial to note that different industries and applications may have specific demands, thus consulting the relevant standards and specifications for the particular application is always advisable.

- Q: What are the different methods of laminating steel coils?

- There exist multiple techniques for laminating steel coils, each possessing its own advantages and applications. The prominent techniques encompass hot rolling, cold rolling, and continuous annealing. Hot rolling involves heating the steel above its recrystallization temperature and subsequently passing it through a sequence of rollers to generate thin sheets or coils. This method is frequently employed for the mass production of steel with a uniform thickness and surface finish. Structural applications such as construction and automotive manufacturing commonly utilize hot rolled steel coils. In contrast, cold rolling entails passing the steel coil through a set of rollers at room temperature. This process not only reduces the thickness of the steel but also enhances its surface finish and mechanical properties. Industries requiring high precision and quality, such as appliance manufacturing, electrical equipment, and automotive components, typically employ cold rolled steel coils. Continuous annealing represents an alternative approach to laminating steel coils. It involves heating the steel coil to a specific temperature and gradually cooling it in a controlled environment. This procedure aids in alleviating internal stresses and enhancing the mechanical properties of the steel, such as strength and ductility. Continuous annealing is frequently utilized to produce high-quality steel coils for applications necessitating superior surface finish and formability, like automotive body panels and household appliances. Additional less prevalent methods of laminating steel coils comprise electro-galvanizing and hot-dip galvanizing. Electro-galvanizing encompasses coating the steel with a zinc layer through an electroplating process, while hot-dip galvanizing entails immersing the steel coil in molten zinc. These techniques primarily serve corrosion protection purposes and are commonly employed in the construction industry, particularly for outdoor structures and infrastructure. To summarize, the various techniques for laminating steel coils encompass hot rolling, cold rolling, continuous annealing, electro-galvanizing, and hot-dip galvanizing. Each approach offers distinct advantages and is selected based on the specific requirements of the application.

- Q: What are the different types of steel coil storage methods?

- There are several different types of steel coil storage methods, including vertical stacking, horizontal stacking, coil cradles, and coil racks.

- Q: How are steel coils used in the production of construction equipment?

- Steel coils are used in the production of construction equipment as they provide a reliable and cost-effective material for manufacturing various components. These coils are often processed and shaped into specific parts, such as frames, chassis, and heavy-duty structures, which make up the foundation and framework of construction equipment. The high strength and durability of steel coils ensure that the equipment can withstand heavy loads, extreme conditions, and repetitive use, making them essential in the construction industry.

- Q: I was watching a documentary on the samurai vs the European knight. It said that the when Japan was being invaded by the (cant remember) they needed a new weapon. The enemies armor made iron swords useless. While steel swords broke when in combat. So to combat this the Japanese made a hybrid sword. They used a special mold that made the swords back iron while the part that makes contact with the enemy was steel. Also the sword was curved so it increased its armor and cutting power. This revolutionary design made the the sword stronger. The iron back made it not break while the steel edge made it cut through the enemies armor. I want to know how iron is stronger than steel, and how steel can cut better than iron.

- Is Iron Stronger Than Steel

- Q: Is there alloys in low carbon steel or non

- Hello, okorder Hoping this can help you. :-)

- Q: What are the different cutting methods for steel coils?

- Steel coils can be cut using various methods depending on specific requirements and desired outcomes. Some commonly used cutting methods for steel coils include: 1. Slitting: Narrower strips can be obtained by cutting the steel coil using a slitting machine equipped with multiple circular blades. The coil is unwound and passed through the blades, resulting in the desired width. Slitting is commonly employed in industries like automotive manufacturing or electrical appliance production, where narrower steel strips are needed. 2. Shearing: This method involves using a shear machine with a straight blade to cut through the steel coil. The blade presses against the coil, cutting it into desired lengths or shapes. Shearing is ideal for applications requiring precise cuts or specific sizes. 3. Laser cutting: A high-powered laser is used to cut through the steel coil in this advanced method. The laser beam is directed onto the coil, melting or vaporizing the metal to create a clean and accurate cut. Laser cutting is highly precise and can be used to cut intricate designs or patterns into the steel coil. It finds applications in industries such as aerospace, automotive, and electronics. 4. Plasma cutting: A high-velocity jet of ionized gas, usually a mixture of oxygen and an inert gas like nitrogen or argon, is employed to melt and remove metal from the steel coil. Plasma cutting is known for its speed and versatility, as it can cut through various metals, including steel. It is commonly used in industries like shipbuilding or construction, where fast and efficient cutting is required. These are just a few of the cutting methods available for steel coils. The choice of method depends on factors such as desired outcome, coil thickness, and specific application requirements. It is advisable to consult with a professional or specialist to determine the most suitable cutting method for your specific needs.

- Q: aLSO, DOES STEEL C45 REFER TO THE CARBON IN IT?ALSO, WHAT IS AIRCRAFT GRADE PLYWOOD AND WHERE DOES ONE GET IT

- chromium nickle steel aka stainless steel exact amount of chrome and nickle will determine type/grade numbers Check the google for steel type/grade Never head of aircraft grade, however,, there is marine grade - normally baltic birch with waterproof glue and no defects i.e. knots, etc. Very strong (also quite expensive) but worth it for the correct applications

- Q: How did the growth of the steel industry influence the development of other industries?

- At least three ways: 1. Steel as a material that other industries could use to do things that couldn't be done before (for example, construction (skyscrapers, long bridges, etc.)) or could now be done at much lower cost and hence increased the size of the industry (automobiles, bearings, etc.)

Send your message to us

Prepainted GI steel Coil/ PPGI / PPGL/ Color Coated Galvanized Steel Sheet in Coi/PPGI/SGCC/SGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords