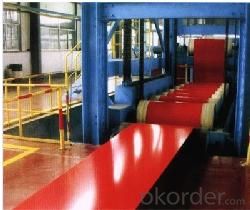

Prepainted GI Steel Coil / PPGI / PPGL Color Coated Galvanized Steel Sheet In Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Standard: | AISI, ASTM, BS, DIN, GB, JIS, JIS,ASTM,GB,AISI | Grade: | galvanized steel coil | Thickness: | 0.15MM-1.5MM*600-1250MM

|

| Place of Origin: | China (Mainland) | Brand Name: | CNBM | Model Number: | 0.15MM-1.5MM*600-1250MM |

| Type: | Steel Coil, Steel Coil | Technique: | Cold Rolled, Cold Rolled | Surface Treatment: | Galvanized, Galvanized |

| Application: | sanwichpanel roofing | Special Use: | High-strength Steel Plate, High-strength Steel Plate,Wear Resistant Steel | Width: | 600-1250mm, 600-1250mm or customizable |

| Length: | 3000-6000mm, 3000-6000mm | Color: | RR, RAL color | Zinc coated: | 30g/m2- 275g/m2 |

Packaging & Delivery

| Packaging Details: | excellent steel seaworthy export package with water and rustproof paper inside. |

| Delivery Detail: | 7-30 days |

Prepainted GI Steel Coil / PPGI / PPGL Color Coated Galvanized Steel Sheet In Coil

| NAME | PPGI/PPGL | GALVANIZED | GALVALUME/ALUZINC |

| CERTIFICATE | ISO9001 | ||

| STANDARD | GB/T-12754 | GB/T-2518 | GB/T-14798 |

| JIS G 3312 | JIS G 3302 | JIS G 3321 | |

| EN 10169 | EN 10142/10427 EN10346 | EN 10215 | |

| ASTM A755 | ASTM A653 | ASTM A792 | |

| GRADE | SGCC | SS GRADE33-80 | GRADE33-80 |

| DX51D+Z | SGCC | SGLCC | |

| DX53D+Z | SGCH | SGLCD | |

| SGCH | SGCD1-SGCD3 | SGLCDD | |

| CGCD1-CGCD3 | SGC340-SGC570 | SGLC400-SGLC570 | |

| CGC340-CGC570 | SGCC | SZACC | |

| DX51D+Z | SZACH | ||

| DX53D+Z | SZAC340R | ||

| MODEL NO | 0.15MM-0.7MM*600-1250MM | (0.13-1.2)*600-1250MM | 0.13MM-1.2MM*600-1250MM |

| ZINC OR AZ Coating | 60-275g/m2 | 60-275g/m2 | 60-150g/m2 |

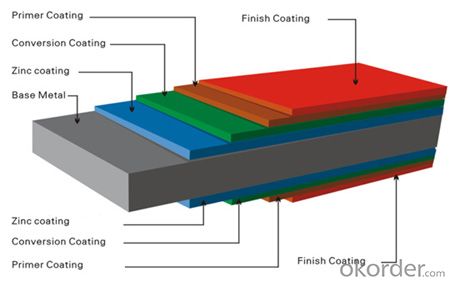

| Painting | top paint 16-25um back paint 7-10 | ||

| TYPE | Steel coil | Steel coil | Steel coil |

| Steel sheets/plates | Steel sheets/plates | Steel sheets/plates | |

| Corrugated steel sheets/plates | Corrugated steel sheets/plates | Corrugated steel sheets/plates | |

| TECHNIQUE | Hot rolled-cold rolled | Hot rolled-cold rolled | Hot rolled-cold rolled |

| -galvalume /galvanized | - galvanized | -galvalume /Aluzinc | |

| -PPGI/PPGL | |||

| SURFACE TREATMENT | Mini/regular/big/zero spangle, | Mini/regular/big/zero spangle, | |

| Chromate treatment /chromate-free treatment /untreated unoile/oiled, | Chromate treatment /chromate-free treatment /untreated unoile/oiled, | ||

| TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, | TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, | ||

| Coating,color | Coating | ||

| APPLICATION | Structural use,roofing,corrugated roofing,commercial use,household appliance, industry,family | ||

| SPECIAL APPLICATION | Wear resistant steel,high-strength-steel plate | ||

- Q: What is the role of steel coils in the production of storage shelves?

- Steel coils are used in the production of storage shelves to provide strength and durability. The coils are processed and shaped into various components of the shelf, such as the frame, shelves, and brackets. This ensures that the shelves are able to withstand heavy loads and maintain their structural integrity over time. Steel coils also offer corrosion resistance, making them suitable for use in storage environments.

- Q: What are the quality control measures for steel coil production?

- Quality control measures for steel coil production are essential to ensure that the final product meets the required standards and specifications. Here are some key quality control measures commonly employed in the steel coil production process: 1. Raw Material Inspection: Before production starts, the raw materials such as steel billets are thoroughly inspected for their chemical composition, mechanical properties, and surface defects. This ensures that only high-quality materials are used in the production process. 2. Process Control: Throughout the production process, various process control measures are implemented to monitor and control critical parameters. These may include temperature control, rolling speed, tension control, and lubrication. Regular checks and adjustments are made to ensure that these parameters are within the specified tolerances. 3. Dimensional and Surface Inspection: Steel coils undergo rigorous dimensional and surface inspections to ensure that they meet the required thickness, width, and length specifications. Surface defects such as scratches, pits, or dents are also carefully examined and minimized to meet quality standards. 4. Mechanical Testing: Mechanical properties such as tensile strength, yield strength, elongation, and hardness are tested on a regular basis. These tests are crucial to ensure that the steel coils possess the desired strength and performance characteristics. 5. Visual Inspection: Visual inspection is an important quality control measure to identify any visible defects or irregularities in the steel coils. Trained inspectors check for issues like cracks, corrosion, or uneven surfaces, and take necessary actions to rectify or reject the faulty coils. 6. Non-Destructive Testing: Non-destructive testing methods like ultrasonic testing, magnetic particle testing, or eddy current testing are often employed to detect internal defects such as voids, inclusions, or discontinuities that may impact the quality of the steel coils. 7. Documentation and Traceability: Proper documentation and traceability of all quality control measures are maintained throughout the production process. This includes recording test results, inspection reports, and other relevant data to ensure transparency and accountability. 8. Continuous Improvement: Quality control measures in steel coil production are not static but subject to continuous improvement. Regular audits, feedback from customers, and analysis of process data are used to identify areas for improvement and implement corrective actions to enhance product quality. By implementing these quality control measures, steel coil manufacturers can ensure that the final product meets the required specifications, performs reliably, and achieves customer satisfaction.

- Q: How are steel coils classified based on their thickness?

- Steel coils are classified based on their thickness into different gauge categories. These categories range from thin to thick, with each gauge representing a specific measurement.

- Q: What bike companies make the best Steel Road bikes?

- Lots of good companies out there. Surly Pacer is one to check out.

- Q: What are the different types of steel alloys used in coils?

- Coils commonly employ various types of steel alloys, each possessing unique properties and characteristics. Some frequently used types include: 1. Carbon Steel: As the most fundamental and widely utilized steel alloy in coils, it boasts low carbon content and renowned strength and durability. Carbon steel coils find extensive application in areas demanding high strength, such as automotive parts, construction materials, and machinery components. 2. Stainless Steel: Comprising an iron, chromium, and other element alloy, stainless steel coils exhibit exceptional resistance to corrosion, formidable strength, and heat resistance properties. They are typically employed in scenarios where shielding against corrosion and staining is pivotal, such as kitchen appliances, medical equipment, and transportation components. 3. Galvanized Steel: Galvanized steel coils are formed by coating regular carbon steel with a layer of zinc, furnishing excellent corrosion resistance and safeguarding the underlying steel from rust. Commonly utilized in outdoor settings like roofing, fencing, and automotive body parts. 4. Alloy Steel: Alloy steel coils are manufactured by incorporating diverse alloying elements like manganese, nickel, chromium, or molybdenum into carbon steel, thereby enhancing the steel's strength, hardness, and wear resistance. These coils frequently find application in industries necessitating high strength and toughness, such as machinery, tools, and construction equipment manufacturing. 5. Electrical Steel: Electrically specialized steel coils are designed explicitly for employment in electrical equipment like transformers and electric motors. These coils possess low electrical resistance and high magnetic permeability, facilitating efficient electricity conduction and magnetic field generation. Typically constructed from a silicon alloy, which enhances electrical and magnetic properties. In conclusion, the selection of a steel alloy for coils hinges upon the specific requirements of the given application, encompassing factors like strength, corrosion resistance, electrical conductivity, and heat resistance.

- Q: How are steel coils inspected for bendability using bend testers?

- Bend testers are specialized machines utilized to inspect the bendability of steel coils, measuring their flexibility and resistance against bending. The inspection process involves multiple steps to guarantee precise and dependable outcomes. To begin with, the steel coil is prepared by securing it firmly in place, typically using clamps or other mechanisms to prevent any movement during testing. This ensures stability and enables consistent and repeatable measurements. Following that, the bend tester is set up according to the specified testing parameters. These parameters usually include the desired bend angle, the speed at which the bend is applied, and the number of cycles to be performed. The bend tester is equipped with a bending mechanism that applies a controlled force on the coil, simulating the bending conditions it may experience in its application or use. Once the bend tester is ready, the bending process commences. The machine gradually applies an increasing force to the steel coil until it reaches the desired bend angle. Careful measurement and monitoring of this force take place throughout the process to ensure accuracy. While the bending process is underway, the machine records and displays significant data, such as the applied force, the angle of bend, and any indications of cracking or other defects. This data is crucial for evaluating the bendability of the steel coil and determining its compliance with required standards. Once the desired bend angle is attained, the coil is released from the bending mechanism, allowing any residual stresses to relax. This relaxation period is essential for observing any potential spring-back effect, where the coil partially returns to its original shape after bending. The amount of spring-back is also measured and recorded for further analysis. Finally, the inspection results are analyzed to assess the overall bendability of the steel coil. If the coil meets the specified bendability criteria, it can be deemed acceptable for its intended application. However, if any cracks, fractures, or excessive spring-back are detected, further investigation and analysis may be necessary to identify the cause and determine appropriate corrective actions. In conclusion, bend testers play a crucial role in inspecting the bendability of steel coils. Through a controlled and systematic process, these machines accurately measure flexibility and resistance to bending, ensuring the quality and reliability of steel coils used in various industries.

- Q: How are steel coils tested for strength and durability?

- Steel coils are tested for strength and durability through various methods such as tensile testing, impact testing, and fatigue testing. Tensile testing involves subjecting the steel coil to tension until it breaks, measuring the maximum force it can withstand. Impact testing involves striking the coil with a heavy object to assess its ability to resist sudden shocks. Fatigue testing involves subjecting the coil to repeated load cycles to determine its resistance to long-term stress. These tests help ensure that steel coils meet the required strength and durability standards.

- Q: What is the role of steel coils in the production of pipes and tubes?

- Steel coils play a crucial role in the production of pipes and tubes as they serve as the primary raw material. These coils are unwound and undergo various processes such as cutting, bending, and shaping to form the desired pipe or tube shape. The steel coils provide the necessary strength, durability, and structural integrity to the final product, ensuring that pipes and tubes can withstand high pressure, corrosion, and other demanding conditions.

- Q: i bought an airsoft gun and it said steel recievers on it im not sure what that is

- it means the receivers are made of steel. the receivers on an airsoft gun is pretty much the body of the gun. So pretty much whatever you see on the outside is steel.

- Q: What are the main raw materials used in making steel coils?

- The main raw materials used in making steel coils are iron ore, coal, and limestone.

Send your message to us

Prepainted GI Steel Coil / PPGI / PPGL Color Coated Galvanized Steel Sheet In Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords