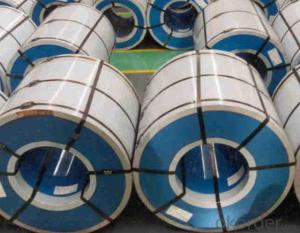

ppgi corrugated steel ,PPGL,PPGI sheet,prepainted steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS,DX51D | Grade: | DX51D | Thickness: | 0.17-1.2mm,0.2-1.2mm |

| Place of Origin: | Tianjin China (Mainland) | Brand Name: | CNBM | Model Number: | ppgi |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | Constuction,building material | Special Use: | High-strength Steel Plate | Width: | 600-1500mm(914/1000/1200/1220/1250mm),600mm-1250mm |

| Length: | coils | Zinc coating: | 60-275g/m2 | Technical: | cold rolled |

| coil ID: | 508mm | coil weight: | 3-5tons | Base steel: | galvanized steel coil,galvalume steel coil |

| Ral color: | available |

Packaging & Delivery

| Packaging Detail: | Seaworthy standard export packing |

| Delivery Detail: | within 30 days once we get the deposite or confirmed the L/C |

Specifications

1 thickness:0.17-1.2mm

2 width:600-1500mm(914/1000/1200/1220/1250mm)

3 Ral card colors available

4 Prime grade ppgi in stock

1 PPGI Description & Specification:

PPGI/PPGL is based on hot dipped galvanized /galvalume steel plate which is dealed with surface treatment( chemical degreasing and chemical conversion treatment )with one layer or several layers of organic coating,and then is baked and cured to finished products .Organic coating with a variety of different colors ,then ppgi also be calledcolor coated steel coil.GI and GL based PPGI/PPGL with both zinc layer and organic paint protection to make its service life 1.5 times longer than galvanized/galvalume steel coils.

PPGI/PPGL with light weight beautifal appearance and good corrosion resistance can be directly processed so it is widely used in light industry,househould

appliances,automotive and construction industry.For avrious types of industrial and civil construction industry,light steel keel,building level board,corrugated board,roller shutter doors. It was designed to protect steel surface from corrosion,extend its life,in the surface coating layer of Zinc and Color PE metal plate,making improvements to its surface characteristics of thin steel plate.

- Q: How are steel coils inspected for surface quality?

- To ensure that steel coils meet the required standards and are defect-free, a meticulous inspection process is carried out using various methods and technologies. The following steps are involved in inspecting the surface quality of steel coils: 1. Visual Inspection: Trained personnel visually examine the entire surface of the coils to detect any visible defects such as scratches, dents, or irregularities. This step allows for the identification of obvious issues through visual observation. 2. Magnetic Particle Inspection: This non-destructive testing method involves applying a magnetic field to the surface of the steel coil and then adding a magnetic particle solution. Any surface cracks or defects cause the magnetic particles to cluster, making them visible under appropriate lighting. This technique effectively detects surface cracks and abnormalities. 3. Eddy Current Testing: Electromagnetic induction is used in this inspection method to identify surface defects. An eddy current probe is moved over the surface of the steel coil, and any variations in the electrical current induced by the magnetic field are detected. This technique is especially useful for detecting surface cracks, pits, or corrosion. 4. Ultrasonic Testing: Ultrasonic waves are employed to inspect the surface of the steel coil for hidden defects like subsurface cracks or inclusions. High-frequency sound waves are transmitted into the material, and any changes in the reflected sound wave pattern indicate the presence of defects. Ultrasonic testing is highly reliable and can detect even the smallest defects within the steel coil. 5. Surface Roughness Measurement: Specialized equipment is used to measure the surface roughness of the steel coil. This measurement helps determine if the surface meets the required smoothness standards. The equipment scans the surface and provides detailed information about the roughness, allowing the inspector to ensure it falls within an acceptable range. In summary, the inspection of steel coils for surface quality involves a comprehensive process that combines visual examination with advanced testing methods such as magnetic particle inspection, eddy current testing, ultrasonic testing, and surface roughness measurement. These inspection techniques effectively identify and evaluate potential defects or surface irregularities, ensuring that the steel coils meet the necessary surface quality standards.

- Q: How are steel coils inspected for bendability?

- Steel coils are inspected for bendability using a variety of methods to ensure their suitability for various applications. One common inspection method is the 3-point bend test, where the coil is subjected to a bending force at three specific points along its length. This test helps determine the coil's resistance to bending without fracturing or breaking. During the 3-point bend test, the coil is placed on a support system with two fixed points and one movable point. A force is then applied to the movable point, causing the coil to bend. The amount of force required to achieve a specific level of bending is measured and compared against acceptable standards. Another method used for inspecting steel coils is the mandrel bend test. In this test, a mandrel of a specific diameter is inserted into the coil and bent to a specified angle. The coil is then examined for any signs of cracking or deformation. This test helps determine the coil's flexibility and ability to withstand bending without damage. Visual inspection is also an important part of the inspection process. Trained inspectors visually examine the coil for any visible defects such as cracks, deformations, or irregularities. They also check for proper coil dimensions and uniformity throughout. In addition to these methods, non-destructive testing techniques like ultrasonic testing or magnetic particle inspection may be used to detect any internal defects or flaws that may affect the bendability of the coil. Overall, a combination of mechanical testing, visual inspection, and non-destructive testing methods are employed to ensure that steel coils meet the required bendability standards. These inspections help ensure the quality and reliability of the steel coils for various industries where bendability is a critical factor.

- Q: How are steel coils used in the manufacturing of agricultural machinery?

- Steel coils are used in the manufacturing of agricultural machinery as they are shaped and cut to create various components such as frames, brackets, and structural supports. These coils provide the necessary strength and durability required for heavy-duty equipment used in farming operations.

- Q: What are the dimensions of steel coils used in the furniture industry?

- The dimensions of steel coils used in the furniture industry can vary depending on the specific application and requirements of the furniture manufacturer. However, typically, steel coils used in the furniture industry have dimensions ranging from 0.20mm to 3.00mm in thickness and 600mm to 2000mm in width. The length of the coils can also vary, but it is commonly around 1000mm to 3000mm. These dimensions allow for flexibility in shaping and forming the steel coils into various furniture components such as frames, springs, and structural supports.

- Q: What are the different types of steel alloys used in coil production?

- There are several types of steel alloys used in coil production, including carbon steel, stainless steel, and high-strength low-alloy (HSLA) steel. These alloys offer varying levels of strength, corrosion resistance, and formability, making them suitable for different applications in industries such as automotive, construction, and manufacturing.

- Q: If I wear a pair of thick wool socks, is walking around in the snow with steel-toed boots going to be a problem? I'm wondering if the steel will make my toes too cold.

- Yes, steel-toe boots are cold, thick wool socks or not. Suggest using Cofra orange colored pull-on knee boots. Non-steel toe cap resistant to 200 joule (one and a half tons of crush protection), penetration resistance, cold insulation to minus 20, ankle protection, heat resistant outer sole 300 degrees for one minute, energy absorption of seat region, slip resistance, the biggest traction cletes I've ever seen and they look like big boots seen the acid trip pretending to be film titled: Yellow Submarine. Available: www fra.it

- Q: How are steel coils used in the production of industrial valves?

- Steel coils are used in the production of industrial valves as they provide a high-strength and durable material for constructing the valve bodies, stems, and other components. The coils are typically shaped, cut, and formed into various valve parts, which are then assembled and welded together to create the final valve product.

- Q: What are the common tests performed on steel coils for quality assurance?

- There are several common tests performed on steel coils for quality assurance purposes. These tests help ensure that the steel coils meet industry standards and customer requirements. One of the most common tests is the dimensional inspection. This involves measuring the length, width, and thickness of the steel coils to ensure they meet the specified dimensions. Any deviations from the required dimensions can indicate a quality issue. Another important test is the visual inspection. This involves a thorough examination of the steel coils for any defects or surface imperfections such as scratches, dents, or rust. Visual inspection is crucial to identify any visual defects that might affect the performance or appearance of the steel coils. Additionally, mechanical tests are performed to assess the strength and durability of the steel coils. Tensile tests are conducted to measure the maximum amount of force the steel can withstand before breaking. This test helps determine the steel's tensile strength, yield strength, and elongation properties. Another mechanical test commonly performed is the hardness test. It measures the steel's resistance to indentation, which is an indicator of its strength and toughness. Hardness tests are typically conducted using methods such as Rockwell, Brinell, or Vickers. Corrosion resistance is also an important aspect of steel coil quality assurance. This is typically evaluated through tests such as salt spray or humidity tests. These tests simulate harsh environmental conditions to assess the steel's ability to resist corrosion. Lastly, chemical composition analysis is performed to ensure that the steel coils contain the required elements in the specified proportions. This analysis helps verify that the steel meets the desired chemical properties, which can significantly impact its performance and suitability for specific applications. Overall, these common tests performed on steel coils for quality assurance purposes help ensure that the coils comply with industry standards, customer requirements, and are fit for their intended use.

- Q: How are steel coils protected against corrosion?

- Steel coils are protected against corrosion through various methods such as applying protective coatings, galvanizing, or using corrosion inhibitors. These measures help to create a barrier between the steel surface and the surrounding environment, preventing the onset of corrosion and extending the lifespan of the coils.

- Q: I'm ordering a Pair of tongs(a tool used to dig quahogs in bays that scrapes the bottom constantly) and what type of metal would be the best to fabricate it, steel or stainless steel?

- Whilst doing a welding course a few years ago the teacher said stainless steel was not its proper name,it is called Heat and Corossion resistant steel,it come in different grades related to its corossion resistance,priced accordingly.Must be welded properly without introduction of carbon to the weld (carbon pickup) or the weld might not be there next time you look dependant on environment.Generally harder to form than mild steel (low carbon steel) so it will tend to be stronger than lcs for the same cross section.steve

Send your message to us

ppgi corrugated steel ,PPGL,PPGI sheet,prepainted steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords