All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

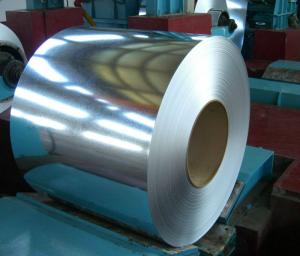

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are stainless steel coils tested for quality and durability?

Stainless steel coils are tested for quality and durability through various methods such as visual inspection, chemical analysis, mechanical testing, and corrosion resistance evaluation. Visual inspection ensures the coils meet the required dimensions, surface finish, and absence of defects. Chemical analysis determines the composition and purity of the stainless steel. Mechanical testing assesses the strength, hardness, and ductility of the coils. Lastly, corrosion resistance evaluation involves subjecting the coils to different environments to assess their resistance to corrosion and ensure long-lasting durability.

How is stainless steel coil used in the production of architectural structures?

Stainless steel coil is commonly used in the production of architectural structures due to its durability, corrosion resistance, and aesthetic appeal. It can be formed, shaped, and welded to create various components such as beams, columns, and cladding panels. These coils are often processed and fabricated into architectural elements that enhance the strength and longevity of structures while providing a sleek and modern appearance.

How is stainless steel coil used in the brewing industry?

Stainless steel coil is widely used in the brewing industry for various applications such as heat exchangers, fermentation tanks, and brewing equipment. The coils are typically used in heat transfer processes to cool down hot liquids or gases, ensuring precise temperature control during fermentation and brewing. The corrosion-resistant nature of stainless steel makes it ideal for contact with acidic liquids and high-temperature environments, ensuring the purity and quality of the beer. Additionally, stainless steel coils are easy to clean and maintain, ensuring hygienic brewing conditions and prolonging the lifespan of the equipment.

How are stainless steel coils manufactured?

Stainless steel coils are typically manufactured through a process called cold rolling. In this process, stainless steel sheets are passed through a series of rollers at room temperature, gradually reducing the thickness and increasing the length. This cold rolling process helps enhance the strength, durability, and surface finish of the stainless steel coils. Additionally, various other steps like annealing, pickling, and cutting may be involved in the manufacturing process to ensure the desired quality and specifications of the coils.

What are the standard lengths available for stainless steel coils?

The standard lengths available for stainless steel coils vary, but common options include 100 feet, 200 feet, and 300 feet.

Wholesale Stainless Steel Coil from supplier in Croatia

Our team of experts is highly experienced and knowledgeable in the stainless steel industry, ensuring that we can provide accurate and detailed technical support to our customers in Croatia. We can assist with product selection, material specifications, and any other technical inquiries you may have.

We understand the importance of timely and efficient delivery, which is why we have established strong relationships with reliable logistics partners. This allows us to provide prompt and hassle-free delivery of our Stainless Steel Coil products to customers in Croatia. We also offer flexible payment terms to accommodate your specific requirements.

Customer satisfaction is our top priority, and we strive to exceed expectations in all aspects of our service. We are committed to building long-term partnerships with our customers by providing exceptional products and support. Trust and reliability are the core values that drive our business, and we take pride in our reputation as a trusted supplier in the stainless steel industry.

If you are in need of Stainless Steel Coils in Croatia, we invite you to contact us and experience the difference of working with a reliable and customer-oriented supplier. Let us help you find the perfect solution for your stainless steel needs.

We understand the importance of timely and efficient delivery, which is why we have established strong relationships with reliable logistics partners. This allows us to provide prompt and hassle-free delivery of our Stainless Steel Coil products to customers in Croatia. We also offer flexible payment terms to accommodate your specific requirements.

Customer satisfaction is our top priority, and we strive to exceed expectations in all aspects of our service. We are committed to building long-term partnerships with our customers by providing exceptional products and support. Trust and reliability are the core values that drive our business, and we take pride in our reputation as a trusted supplier in the stainless steel industry.

If you are in need of Stainless Steel Coils in Croatia, we invite you to contact us and experience the difference of working with a reliable and customer-oriented supplier. Let us help you find the perfect solution for your stainless steel needs.