Pre-painted Galvanized Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color,

then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. 2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• Excellent corrosion resistance

• Excellent weather resistance

• High strength

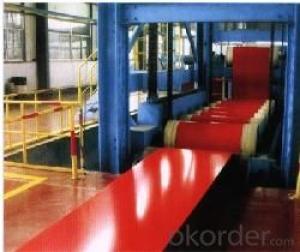

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the dimensions of steel coils?

- The dimensions of steel coils vary depending on factors such as the specific type of steel, the intended use, and industry standards. Generally, steel coils can range in width from a few inches to several feet, with thicknesses typically ranging from a fraction of an inch to several millimeters. The inner diameter of a steel coil can also vary, with common sizes being 20 inches and 24 inches. Ultimately, the dimensions of steel coils are determined by the specific needs and requirements of the end user.

- Q: What are the different types of steel surface finishes for coils?

- There are several types of steel surface finishes for coils, including hot rolled, cold rolled, galvanized, and coated finishes. Each finish offers unique properties and characteristics, such as improved strength, corrosion resistance, or aesthetic appeal. The choice of finish depends on the specific application and desired outcome for the steel coils.

- Q: Steel roofing info. Pros and cons on steel roofing?

- Steel roofing Pro...life of product is much longer then Asphalt shingles....Looks great...multi colors.......Just love the stuff... Cons....More costly then singles at first but since it last longer it is really a better buy.......

- Q: looking for a good pocket knife. i keep going through these 440 steel pocket knives with every day work usage. this will be my 4th. even when i use a whetstone they stay sharp for a short period of time but the edge does not last, 440 is too soft! what is a good steel to look for in a pocket knife? also what are some good brands. ive been using gerber and buck sofar. if you could recommend me a few mid/small sized knives i would greatly appreciate it!

- We hear it all the time and to be honest, it’s really, really hard to simply tell you what the ultimate pocket knife is. That’s because there are so many different knives on the market today and each one is suited to a different user and application. Of course there is a bunch of crap out there which we will endeavor to ensure you steer clear of but even after weeding those out you’re left with literally hundreds of choices from top quality manufacturers.

- Q: Well im currently doing a project. Wanna help me? Because trust me, i really need it. You know how steel was created in China? If you didnt, you just learned something newww(: but anyways got any info on that? Websites? or just info from websites? Well lemme know because if its the best you get Best Answer Easy points right? (: Okay thanksss (:

- Steel is created in a primitive way whenever iron oxide ore (red dirt) is mixed with wood and burned. Seemingly everyone has a pet theory how their own selected country was the first to notice and do it on purpose. Regards, Larry.

- Q: I noticed that Jimmy Page finger picked on a steel acoustic guitar on quite a few tracks like Stairway to heaven and other ones and I was wondering how did he do it? I know it is more difficult to finger pick on a steel acoustic because of the rougher steel strings and higher tensions so I was wondering do they make specific strings that allow for fingerstyle playing? Also Randy Rhoads finger picked a steel acoustic on Dee along with a Classical guitar.

- First okorder /... In truth their are many, many players who finger pick acoustic guitars, once you get the hang of the various picking patterns it's not extremely difficult to do. There aren't really any specific strings that are required to finger pick. It will mostly come down to the players preference and the type of music they are doing. It is actually more difficult to finger pick an electric guitar since you have less room between the strings and the pickup so you will find that a lot of times you will hit the pickup with the metal finger pick which can be a bit disturbing but practice helps. Pat SImmons of the Doobie Brothers uses finger picks on a Gibson ES335 all the time.

- Q: How are steel coils used in the production of steel pipes?

- Steel coils are an essential component in the production of steel pipes. These coils serve as the raw material that is used to manufacture the pipes. The first step in the process involves unwinding the steel coil and feeding it into a machine called a slitter. The slitter cuts the coil into narrower strips of the desired width. This width is crucial as it determines the diameter of the steel pipes that will be produced. Once the steel coil has been slit into strips, the next step is to feed these strips into another machine called a forming mill. The forming mill gradually shapes the strips into a cylindrical shape by passing them through a series of rollers. These rollers apply pressure and bend the strips until they take on the form of a pipe. To ensure the durability and strength of the pipes, they undergo a welding process. The ends of the strip are heated and fused together using a high-frequency electric current, resulting in a continuous weld along the length of the pipe. This weld provides structural integrity and prevents any leakage or weak spots in the pipe. After the welding process, the pipes go through a sizing and shaping process. They are passed through additional rollers and gradually reshaped to achieve the desired dimensions, including the final outer diameter and wall thickness. Finally, the pipes are cut to the desired length and undergo various finishing processes such as straightening, testing, and coating. These finishing steps ensure that the pipes meet the required specifications and are ready for use in various applications, such as plumbing, construction, and oil and gas industries. In summary, steel coils are the starting point for the production of steel pipes. They are slit, formed, welded, sized, shaped, and finished to create durable and high-quality pipes that can be used in a wide range of industries.

- Q: Im looking at some knives and am wandering if they use good steel one is this case knife and its 54 dollars Do they use good steel or not Iv never had a good experience with Case but am wandering if they use good steel now? if you all have any other recommendations let me hear them I got my Selection from here so any others wont hurt. so basic break down does case use good steel know?

- Case okorder /

- Q: How are steel coils used in the automotive stamping process?

- Steel coils are a critical component in the automotive stamping process. These coils are essentially large rolls of steel that are unwound and fed into stamping machines. The coils are typically made of high-quality steel and come in various thicknesses and widths to meet the specific requirements of different automotive parts. During the stamping process, the steel coils are fed through a series of dies and presses that shape and form the metal into the desired automotive components. The coils are unwound and passed through a straightener to remove any bends or twists, ensuring a smooth and consistent feed into the stamping machine. The stamping machine then uses a combination of hydraulic or mechanical force to press the steel coil against a die, which is a specially designed mold that gives shape to the metal. The die is often made of hardened steel to withstand the pressure and provide accurate and repeatable results. The steel coil is fed into the stamping machine at a high speed, and as it passes through the die, the metal is formed into various automotive parts such as body panels, doors, hoods, fenders, and other structural components. The stamping process allows for high precision and consistency in producing these parts, ensuring they meet the required specifications and tolerances. Once the metal is formed, it may undergo additional processes such as trimming, piercing, or bending to achieve the final shape. These processes are often performed in subsequent stamping stations or by using progressive dies that combine multiple operations into a single pass. Overall, steel coils play a vital role in the automotive stamping process as they provide the raw material required to produce various components. The use of steel ensures the necessary strength, durability, and safety of the automotive parts while maintaining cost-effectiveness and mass production capabilities.

- Q: I have some steel wool and a charged 9V Battery, when I connect 2 wires to the battery, then touch the wool with the ends of the wires the wool instantly starts burning, but when I connect 2 wires to the piece of steel wool (a new piece not same one of course) and touch the battery with the ends of the wire nothing happens (see image...)

- Steel Wool 9v Battery

Send your message to us

Pre-painted Galvanized Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords