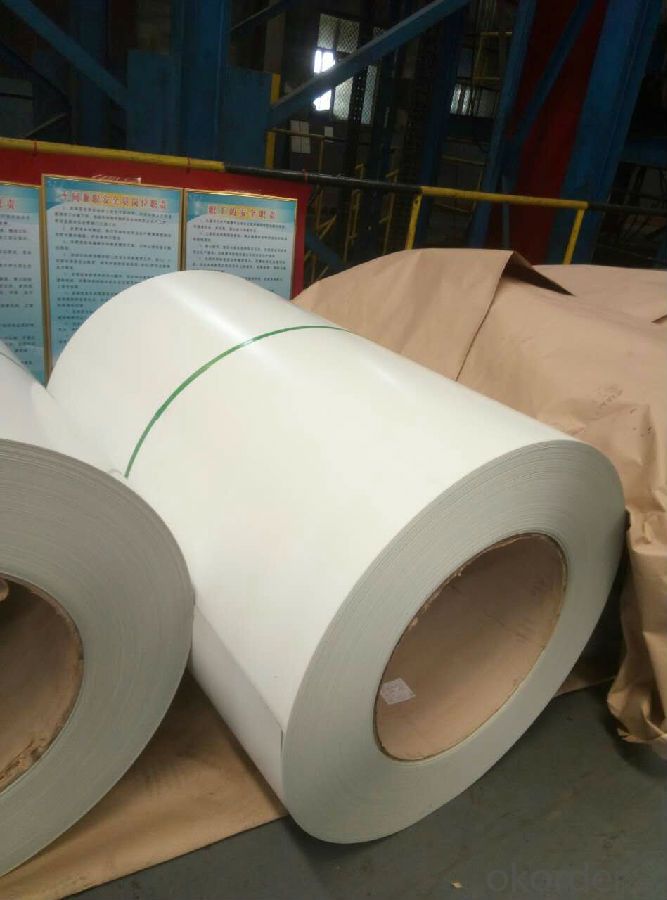

PPGI/PPGL/GI/GL/Color Coated Prepainted Steel Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

We have devoted to manufacture steel coils for 13 years. As the biggest manufacture in Hebei China, we have two large factory and 8 production lines, sincerely welcome to your visit if possible.

1, Production Introduction: PPGI are prepainted galvanized steel coils, used for making roof, advantage is can be used at least 10 years.

2, Product feature:

① We're factory, products has the best price for you.

② We have 8 production lines, have the fastest delivery time for order

③ All colors can be produced by our factory.

④ Product can accept any test before shipment.

3,Parameter list:

① Product Name:PPGL

②Thickness:0.2-1.0MM

③ Width:914-1250MM

④ Az Coating:30-275 G/M2

⑤Coil Weight:3-5MT

⑥Coil ID:508MM

⑦Packing :Standard Export Seaworthy Shipping Packaging

⑧Payment Terms:T/T Or irrevocable LC at sight

⑨Delivery Time:

10 days after advance is confirmed if order≤100MT

15 days after advance is confirmed if 100MT≤order≤200MT

20 days after advance is confirmed if 200MT≤order

4,

- Q: Hi, I would like to know if steel is an important material in desalination plants. If it is, could you specify what type of steel is used (i.e. flat steel products, long steel products, etc). Thanks.

- no u idiot

- Q: I had heard of steel braided fuel lines but ive also seen some air and coolant lines that are steel braided. Are these commonly used? I guess what I'm asking is if its a good idea to use them.

- Steel braided line are mainly use in turbulence areas, where they need to be protected. i would recommend replacing your brake line with it but not your coolant or air lines. there are other materials that are well suitable for coolant and air lines.

- Q: What is stainless steel 316, and what are its properties and uses?

- For machined aspects 416 cautioned. For welded aspects 316 is cautioned. besides the shown fact that 316 supplies a greater advantageous corrosion resistance. oftentimes the only benefit for 416 is machinability others than that 316 is greater advantageous

- Q: How are steel coils tested for flatness and straightness?

- Steel coils are tested for flatness and straightness using various methods such as visual inspection, measurement tools like straightedges or laser devices, and specialized equipment like leveling machines. These tests ensure that the steel coils meet the required standards and are free from any deformities or deviations in their flatness and straightness.

- Q: What are the different types of steel coil packaging materials?

- There are several different types of steel coil packaging materials, including steel strapping, stretch film, plastic wrap, metal bands, and wooden crates. These materials help protect and secure steel coils during transportation and storage.

- Q: What are the different types of steel coil cutting machines?

- In the market, there is a wide range of steel coil cutting machines available, each tailored to meet specific needs and requirements. Some commonly used types include: 1. Slitting Machines: These machines are utilized to cut steel coils into narrower strips. Equipped with multiple circular blades, they are capable of making precise cuts along the length of the coil, enabling the production of narrower coils or strips. 2. Cut-to-Length Machines: Designed to cut steel coils into specific lengths, these machines possess the ability to accurately measure and cut the coil to the desired length, ensuring uniformity and precision. 3. Rotary Shears: Rotary shears are robust cutting machines that can handle thicker and larger steel coils. Utilizing a rotating blade, they are suitable for cutting thicker gauge materials. 4. Multi-Blanking Machines: Intended for cutting steel coils into multiple smaller blanks simultaneously, these machines have the capability to cut the coil into various shapes and sizes. This makes them ideal for producing multiple parts from a single coil. 5. Slit and Cut-to-Length Combination Machines: These machines integrate the functionalities of both slitting and cut-to-length machines, enabling the cutting of narrow strips and lengths in a single process. They offer versatility and efficiency, saving time and increasing productivity. Each type of steel coil cutting machine possesses distinct advantages and is suitable for specific applications. The choice of machine depends on factors such as coil thickness, desired strip width, required length accuracy, and production volume.

- Q: How are steel coils tested for compliance with industry standards?

- To ensure compliance with industry standards, steel coils undergo a series of rigorous quality control measures. These tests are conducted to verify that the coils meet necessary specifications and are suitable for various applications. Among the primary tests performed on steel coils is dimensional inspection. This entails measuring the thickness, width, and length of the coils to ensure they fall within specified tolerances. Any deviations from the required dimensions may indicate manufacturing defects or potential issues during fabrication. Another crucial test is visual inspection, where trained inspectors meticulously examine the coils for surface defects like scratches, dents, or cracks. Identifying and rectifying these defects is essential as they can impact the performance and durability of the steel coils before they are supplied to customers. Additionally, mechanical properties testing is carried out to assess the strength, elasticity, and toughness of the steel coils. This includes conducting tests for tensile strength, yield strength, and elongation measurements. These evaluations help determine if the coils are suitable for specific applications and if they meet the required performance standards. Furthermore, chemical composition analysis is performed to validate the elemental composition of the steel coils. This analysis is crucial as it ensures that the steel meets the required chemical requirements, including the presence of specific alloying elements. Deviations in composition can significantly affect the overall quality and performance of the coils. Corrosion resistance testing is also of great importance, particularly for coils used in environments with high humidity or exposure to corrosive substances. Coils are subjected to simulated real-world conditions, such as salt spray or humidity chambers, to evaluate their resistance to corrosion. Lastly, various non-destructive testing techniques, including ultrasonic testing and magnetic particle inspection, are employed to detect internal defects or discontinuities in the steel coils. These tests assist in identifying any hidden flaws that could compromise the structural integrity of the coils. In summary, steel coils undergo a comprehensive array of tests to ensure adherence to industry standards. By conducting these tests, manufacturers can guarantee that the coils meet the required specifications, thereby providing customers with high-quality products tailored to their specific needs.

- Q: I read that contrary to popular belief, today's folded steel swords are only made that way for tradition and cosmetics. In the past steel was very impure and therefore had to be folded in order to make a good sword. Today's steel manufacturing provides very pure steel and so folding the metal only makes it look nicer, but does nothing to improve the function of the blade.What do you think of this?

- Folding Sword

- Q: I mean about if I had a piece of metal, how can i decide that's iron or steel?Sorry for bad English.

- Iron is a chemical element with the symbol Fe, that has no engineering application as it is very soft. You are not likely to come across a piece of metal of pure Iron. Steel is an alloy of Iron that is widely used with different types for various application. The type depends on the alloying elements. An old and rough way of identifying them is to use a chart, that shows the spark pattern when they are subjected to grinding.

- Q: How are steel coils used in the manufacturing of construction bulldozers?

- Steel coils are used in the manufacturing of construction bulldozers primarily for their strength and durability. These coils are typically transformed into various components, such as the bulldozer's frame, blade, and tracks, which require robust materials to withstand the heavy-duty tasks and harsh operating conditions. The steel coils are processed and shaped into these parts, ensuring that the bulldozer can effectively push, lift, and carry heavy loads while enduring the rigors of construction sites.

Send your message to us

PPGI/PPGL/GI/GL/Color Coated Prepainted Steel Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords