Pre-Painted Galvanized Steel Sheet,Coil with High Quality Yellow Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

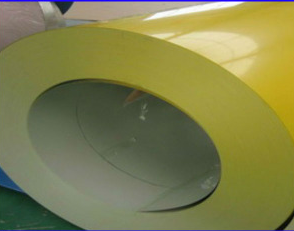

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the production of HVAC ductwork?

- Steel coils are commonly used in the production of HVAC ductwork due to their durability and strength. The coils are typically made of galvanized steel, which provides protection against corrosion and extends the lifespan of the ductwork. The manufacturing process begins with the steel coils being unrolled and cut into the desired length. The coils are then fed through a machine that shapes the steel into a rectangular or round duct form. This shaping process can be done using various techniques such as roll forming or press braking. Once the steel has been formed into the desired duct shape, it is then joined together using various methods such as welding or locking mechanisms. Welding is often used for rectangular ducts, while locking mechanisms like snap locks or Pittsburgh seams are commonly used for round ducts. These joining techniques ensure that the ductwork is secure and airtight. After the ductwork has been assembled, it may undergo additional processes such as insulation or lining. Insulation helps to reduce heat loss or gain, while lining can improve the acoustic properties of the ductwork. These additional steps are often done to meet specific requirements or regulations. Overall, steel coils play a crucial role in the production of HVAC ductwork as they provide strength, durability, and protection against corrosion. The versatility of steel allows for various shapes and sizes of ductwork to be fabricated, making it a popular choice for HVAC systems.

- Q: and which one is better?i'm looking into buying some aftermarket headers, but companies make them in both chrome and stainless steel

- I know nothing of aftermarket headers so can't help you there, but - chrome is a coating on metal. Stainless Steel is a type of metal.

- Q: Building the bulwurk, general use on trawlers. What kind of steel is best suited.

- How big is your trawler going to be and what use, The ones you see off the Alaska Coast or a Gulf Coast Shrimper? My preference in today's economy would not make sense and that is Aluminum.....not steel at all, maybe even Fiberglass, but $$$$ talk so Steel is cheaper, but you need to know what you are doing. The designer of the hull should have specified the right /preferred grade. It today's world there are many more choices available. You use a mild steel, most often grade A or B, but some applications call for grade D. Check your blue prints and list of materials. Edit. Ok I understand. There are 2 ways to go. One is use a relatively cheep steel and use higher cost epoxy primers and paint, often requiring special surface preparation just before priming, or two, using a much higher cost steel with more chrome and nickel in it. Grades that begin with #3xxx These are weldable with rods that are available, and can be welded directly to mild steels. However these are 3X the cost. If your a Shrimper, I'm guessing gulf coast. I worked with several boat yards in the 70's installing spray urethane foam for insulating there holes. So I've been around lots of small yards from Florida to Texas. I'd call the nearest steel warehouse and ask what they would recommend. You might find what you want at a scrap yard. I've lucked out several times picking up 1/4 plate scrap$ and I'd bet the scrapyard guy would know just what you need. I know there are places to get what you need in Mobile and New Orleans. Good luck!

- Q: I want to buy a VERY sturdy bunkbed, but don't know which one would be better with not getting loose or falling apart.

- Metal/Steel. :)

- Q: How are steel coils used in the production of electrical switches?

- Steel coils are used in the production of electrical switches as they act as the core of the electromagnetic system. When an electric current passes through the coil, it creates a magnetic field which attracts or repels a movable metal component, allowing the switch to open or close. This mechanism is crucial for controlling the flow of electricity in various electrical devices and systems.

- Q: How are steel coils used in the production of electrical enclosures?

- Steel coils are used in the production of electrical enclosures to provide structural strength and durability. The coils are typically cut and bent into specific shapes to form the body and panels of the enclosure. This helps to protect the electrical components inside from external elements and ensure safe operation.

- Q: How do steel coils contribute to the automotive aftermarket?

- The automotive aftermarket heavily relies on steel coils to manufacture a wide range of automotive parts and components. This secondary market deals with the sale of vehicle parts, accessories, and services after the initial purchase of the vehicle. Steel coils find their application in the production of several automotive aftermarket products, including springs, suspension components, chassis parts, and body panels. These coils are typically made from top-notch steel alloys that possess the desired characteristics of strength, durability, and performance. Springs are one of the primary uses of steel coils in the automotive aftermarket. These coiled springs play a crucial role in various automotive systems like suspension, brakes, and clutches. They provide the necessary support, stability, and shock absorption to ensure smooth and safe vehicle operation. Not only that, but steel coils also contribute to the manufacturing of chassis parts, which are vital for maintaining the vehicle's structural integrity and safety. Chassis parts made from steel coils include frame components, cross members, and reinforcement panels, which greatly enhance the overall stability and durability of the vehicle. Moreover, steel coils are extensively utilized in the production of body panels, such as doors, hoods, fenders, and roofs, which are commonly replaced or customized in the automotive aftermarket. These body panels, manufactured from steel coils, not only enhance the vehicle's aesthetics but also provide protection and resistance against impacts. In conclusion, steel coils play a critical role in the automotive aftermarket by facilitating the production of various parts and components necessary for vehicle repair, customization, and improvement. Their high strength, durability, and versatility make them an indispensable raw material, perfectly meeting the demanding requirements of the automotive industry.

- Q: How do steel coils contribute to the manufacturing of electrical appliances?

- Steel coils are essential components in the manufacturing of electrical appliances as they are used to create the core of transformers and electromagnets. These coils, made from steel, provide the necessary magnetic field required for the functioning of electrical appliances such as refrigerators, televisions, and washing machines.

- Q: How do steel coils contribute to the HVACR industry?

- Steel coils play a crucial role in the HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) industry by serving as a primary component in various applications. These coils are typically made from a durable and corrosion-resistant material, such as stainless steel or galvanized steel, which ensures their longevity in demanding HVACR environments. One of the most common uses of steel coils in the HVACR industry is in air conditioning systems. These coils are responsible for transferring heat between the refrigerant and the surrounding air. The coils, often referred to as evaporator coils, absorb heat from the indoor air, cooling it down and removing moisture. They then release the heat outside through a condenser coil, allowing for efficient cooling and dehumidification of the air. Steel coils are also utilized in heat exchangers, which are vital components in HVACR systems. Heat exchangers transfer thermal energy between two fluids, allowing for efficient heating or cooling. Steel coils, often in the form of finned tubes, provide a large surface area for heat transfer and help enhance the overall efficiency of the system. Furthermore, steel coils are extensively used in the construction of ductwork, which is the network of channels that distribute conditioned air throughout a building. These coils are formed into various shapes and sizes to fit specific ductwork designs, ensuring optimal airflow and temperature control. Additionally, the durability and strength of steel coils make them suitable for withstanding the pressure and forces exerted by airflows in duct systems. In refrigeration systems, steel coils are integral to the process of transferring heat out of an enclosed space, such as a refrigerator or freezer. The coils, often referred to as condenser coils, release heat from the refrigerant as it changes from a high-pressure gas to a high-pressure liquid. This allows for the cooling and preservation of perishable goods, making steel coils essential in the food service and cold storage industries. Overall, steel coils contribute significantly to the HVACR industry by enabling efficient heat transfer, optimal temperature control, and reliable operation of various HVACR systems. Their durability, corrosion resistance, and versatility make them a crucial component in providing comfortable and controlled environments in residential, commercial, and industrial settings.

- Q: What brand steel tapes are of good quality?

- Durable durable depends on your personal use frequency, the high frequency nature is easy to wear, resulting in scale. If you like fuzzy units if buying tape need verification it is best to buy the Great Wall Seiko goods, because the time to measure the number of verification inspection of steel tape, basically qualified rate of the Great Wall Seiko steel tape can reach one hundred percent.

Send your message to us

Pre-Painted Galvanized Steel Sheet,Coil with High Quality Yellow Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords