Pre-Painted Galvanized/Aluzinc Steel Coil With High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-Painted Galvanized/Aluzinc Steel Coil With High Quality

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

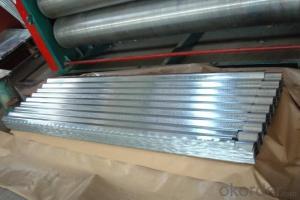

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the manufacturing of industrial filters?

- Steel coils are used in the manufacturing of industrial filters as the primary material for constructing the filter frames. These coils are shaped and welded to form a durable and rigid structure that provides support and stability to the filter media. The steel coil frames not only ensure the longevity of the filter but also enable efficient filtration by maintaining the desired shape and preventing media sagging or distortion.

- Q: What are the common methods of packaging steel coils for transportation?

- There exists a variety of conventional techniques for packaging steel coils for transportation. One frequently employed approach involves the utilization of steel strapping or bands to fasten the coils together. This method entails tightly encircling the coils with steel bands and securing them using metal buckles or seals. The strapping serves to maintain the coils in position and prevent any shifting or rolling during transportation. Another popular technique entails the use of wooden pallets or skids to stack and transport the steel coils. The coils are positioned onto the pallets and secured with steel strapping or bands. This approach ensures stability and facilitates easy handling and loading onto trucks or other means of transportation. Furthermore, certain steel coils are enclosed within wooden crates or boxes. These crates are typically constructed from robust and durable wood and are designed to shield the coils from external impacts or damage during transportation. To enhance strength and stability, the crates are frequently reinforced with steel bands or strapping. In addition to the aforementioned methods, specialized containers or units are employed to package certain steel coils. These containers are specifically engineered to accommodate and secure steel coils for transportation. They often possess integrated mechanisms or features that facilitate the loading and unloading of the coils in a safer and more efficient manner. It is important to acknowledge that the particular method of packaging steel coils for transportation can vary depending on factors such as the size and weight of the coils, the mode of transportation, and any specific requirements or regulations that may be in effect.

- Q: so i've started learning to play guitar in the past few weeks, and i'm using my sister's old guitar which isn't in very good condition, so i'm planning on buying a new one, but which would be better to buy, nylon string or steel string?

- It rather relies upon on what type of music you're enjoying, nylon string guitars have a mellow, softer tone than steel strings, the feel of the nylon strings (a minimum of to me) are reliable, in my opinion, i might ought to declare nylon is extra suitable, large for finger choosing and a effective tone. once you're searching for a guitar, you are able to flow out to a close-by guitar save, and attempt the two out for your self, in straight forward terms then will you comprehend for specific.

- Q: What are the different types of steel coil coatings for heat resistance?

- There are several different types of steel coil coatings that provide heat resistance, including silicone-modified polyester (SMP), polyvinylidene fluoride (PVDF), and high-temperature silicone.

- Q: What is the cost of steel coils?

- The cost of steel coils can vary depending on factors such as the type of steel, quality, quantity, and market conditions. It is best to contact suppliers or check market prices for the most accurate and up-to-date cost information.

- Q: How are steel coils different from steel sheets?

- Steel coils and steel sheets are both made from the same material, which is steel. However, they differ in terms of their shape and size. Steel coils are long, continuous rolls of steel, usually wound up in a coil form, while steel sheets are flat, rectangular pieces of steel. The main difference lies in their applications - steel coils are commonly used in industries where large quantities of steel are required for manufacturing processes, such as automotive or construction, whereas steel sheets are often used for smaller-scale projects or as a raw material for further processing.

- Q: But we've had a problem with bears being attracted to the water in the Intex Inflatable pools, the bear would come at night every so often and push on the sides letting out the water.Would a bear be able to bend a steel frame before I go and spend money?

- depends on the steel thickness and positioning. frm your question I'm guessing you're not really well versed in steel framing or use... im guessing whatever you build, a bear can destroy. if i was to build it not even 100 bears can destroy it. it doesn't require much steel, it's just about bracing the positing of steel and some design.

- Q: My 8-year-old and 9-year-old boys have approached me with an interesting question. Does fire burn steel? One says yes, the other says no. Help me to settle yet another debate :)

- It can burn it... but not the sort of fire you would find at home... Ive actually done it before in a silversmithing class with a very hot blow torch. It takes a long time, the metal first goes pink, then glowing orange red... it stays that way for a while, and then 'cracks' kind of loudly and basically disintergrates very suddenly. A torch this hot has a very hard (noisy) flame which is very transparent. But you cant burn it in the fireplace.

- Q: What are the factors affecting the formability of steel coils?

- The factors affecting the formability of steel coils include the composition and microstructure of the steel, the thickness and width of the coil, the temperature and speed of the forming process, the lubrication used during forming, and the presence of any surface defects or contaminants.

- Q: Hey everyone.I have a whetstone and a honing steel. I purposely tried to make one of my knives less sharp twice to see how well the whetstone and honing steel would work.It even seemed that when I was using my whetstone it wasn't as sharp as it was when I used my honing steel, but when I also used my honing steel after having sharpened my knife on the whetstone, it was razor sharp.I was wondering, is the whetstone only supposed to be used when the knife edge isn't as flat anymore or something? Like, only when it doesn't really have an edge anymore?Please explain your answer.Thanks everyone.

- In general, whetstones will actually remove metal in order to sharpen a blade, and the angle they're used at is important too. A steel will just straighten the blade between uses, not actually remove metal. The effect is to make it sharper than it was just before, but only because it's straighter. Using a knife makes the very thin edge kind of flatten or even fold over a bit, or get wavy, etc...so the steel just straightens it back out (imagine what happens when the very thin blade gets pressed down repeatedly on a cutting board, or even cuts through foods repeatedly). (A whetstone is used only when steeling finally just isn't enough to get the blade sharp as needed.) .

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil With High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords