Pre-painted Aluzinc Steel Coil Used for Industry with Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

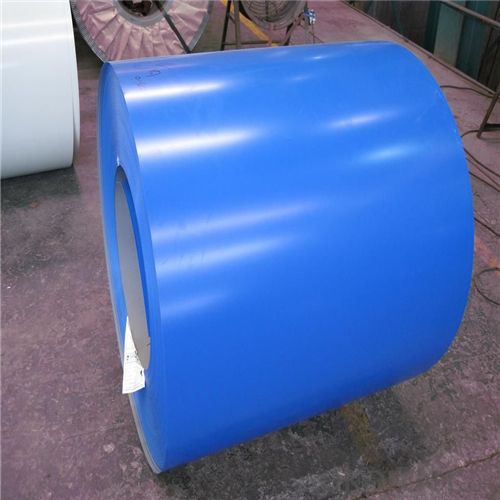

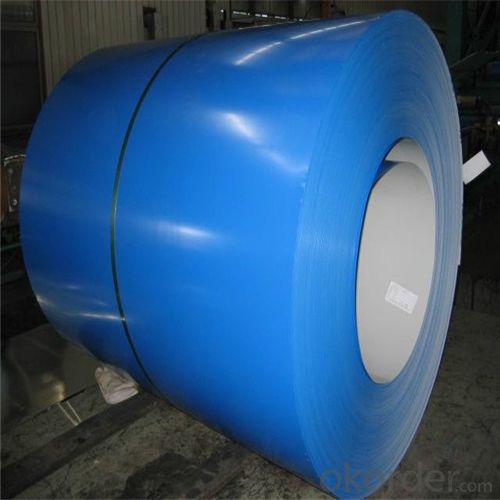

Pre-painted Aluzinc Steel Coil Used for Industry

1.Structure of Pre-painted Aluzinc Steel Coil Description

With aluzinc steel as base metal, after degrease and chemical treatment and liquid dope with several layers of color, then after firing and cooling.

2.Main Features of Pre-painted Aluzinc Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

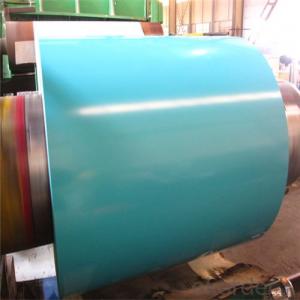

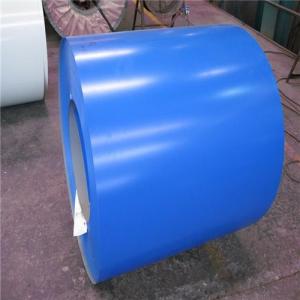

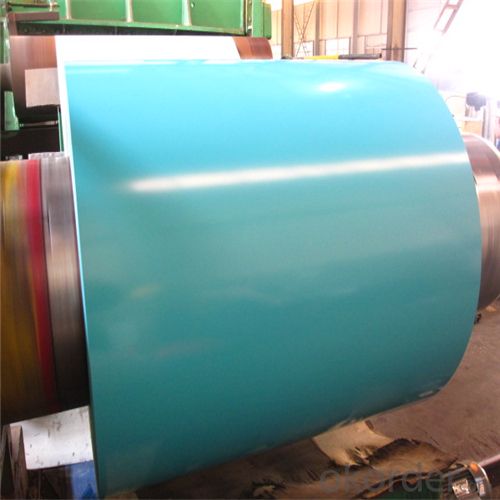

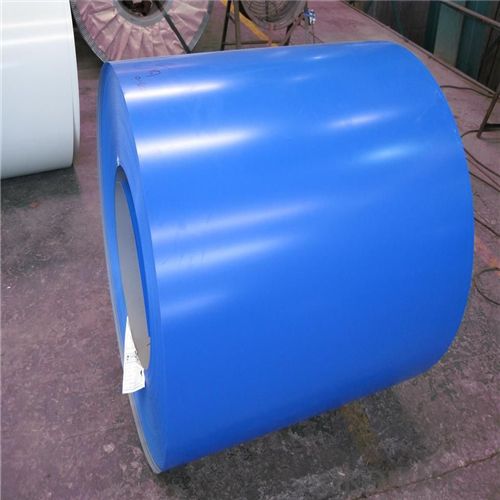

3. Pre-painted Aluzinc Steel Coil Images

4. Pre-painted Aluzinc Steel Coil Specification

Pre-painted Aluzinc Steel Coil | |

Thicknenss | 0.18mm-1.5mm |

Width | 900-1250mm |

Coating mass | 30-185g/㎡ |

Paint | PE, PVDF, PU |

Color | RAL Scale |

Coil weight | 3-7mt |

Coil inner diameter | 508 or 610mm |

5.FAQ of Pre-painted Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. So we can give you commonly 50days.

- Q: What are the different types of steel surface treatments for coils?

- There are several types of steel surface treatments for coils, including hot-dip galvanizing, electro-galvanizing, galvannealing, and organic coating. Hot-dip galvanizing involves immersing the steel coil in a bath of molten zinc to create a protective layer. Electro-galvanizing applies a thin layer of zinc to the surface using an electrical current. Galvannealing is a process that combines galvanizing and annealing to create a zinc-iron alloy layer. Organic coating involves applying a protective layer of paint or other organic material to the steel surface.

- Q: What is the average shelf life of a steel coil?

- The average shelf life of a steel coil can vary depending on various factors such as the type of steel, storage conditions, and handling practices. Generally, steel coils can be stored for several months to a few years without significant degradation in quality. However, it is important to ensure proper storage conditions, such as maintaining a dry and clean environment, protecting against moisture and corrosion, and avoiding excessive pressure or stacking. Regular inspection and maintenance can help to extend the shelf life of steel coils even further.

- Q: How are steel coils used in the production of oil and gas pipelines?

- Steel coils are used in the production of oil and gas pipelines as they provide the necessary strength and durability required for transporting petroleum products over long distances. These coils are formed into pipes through various manufacturing processes, such as hot rolling or cold forming, and then welded together to create a continuous pipeline. The high tensile strength of steel coils ensures that the pipelines can withstand the high pressure and harsh environmental conditions associated with oil and gas transportation.

- Q: How are steel coils used in the food processing industry?

- The food processing industry commonly uses steel coils for various purposes. One primary use is in the production of food packaging materials like cans and containers. These coils are transformed into thin sheets or strips and then shaped and sized for packaging different food products. Steel coils are also utilized in manufacturing equipment and machinery used in food processing plants. This includes crucial machines like conveyors, mixers, and slicers, which enable efficient and automated food processing. Steel's durability and strength make it an ideal material for these types of equipment, as it can withstand heavy usage and maintain its structural integrity. Additionally, steel coils are used in constructing storage and refrigeration facilities within the food processing industry. These coils are transformed into durable and insulated panels that create walls and ceilings in cold rooms, freezers, and warehouses. Steel's excellent thermal properties help maintain the desired temperature and prevent spoilage of perishable food items. Moreover, steel coils are employed in the production of cooking and baking equipment, such as ovens and grills. These coils are transformed into heating elements that provide consistent and efficient heat distribution during the food preparation process. This ensures that food is cooked or baked evenly, resulting in high-quality and delicious products. Overall, steel coils play a crucial role in the food processing industry by providing necessary materials for packaging, equipment, and infrastructure. Their strength, durability, and thermal properties make them a preferred choice for various applications within this industry, ensuring the production of safe and high-quality food products.

- Q: i need working shoes for women that have steel toe shoes? What store do they sell them in . i live in c.a.

- Walmart Steel Toe Shoes

- Q: Can steel coils be cut to length?

- Yes, steel coils can be cut to length using various cutting methods such as shearing, slitting, or sawing.

- Q: A roll of 1 meters wide color steel roll about how many tons?

- Generally speaking, it will be about 4 tons, the export may be larger, but 10 tons of papers have not yet seen

- Q: So I was thinking about doing corset waist training and I wanted to know where I can get a real steel boned corset?

- Hi, okorder / There are 3 types of corsets: Fashion corsets, Authentic corsets and Waist training corsets. The fashion corsets are designed for light enclasping of body. They are made with plastics bones usually. The authentic corsets can reduce your waist size about 4 - 5 and the waist training corsets about 6. They both are made with steel spirals and flat bones. The waist training corsets are recommended for experienced wearers only. Look on info pages of the seller. The corsets reinforced with plastic bones are cheap with low durability.

- Q: Is this a strong, durable piece of steel that can take abuse? I'm thinking about using it on a small project.

- If you made up the right rigging you could probably suspend a Volkswagon with that, but certainly a refrigerator. It's flexible as steel goes - it's not rigid like tool steel, for instance. Since you ask about tempering and you are shopping at Home Depot, it should be just fine for a home project, if it looks like it will suit. Building a bridge or a machine tool, no.

- Q: Does Steel Cut Oatmeal have the same health benefits as Old Fashioned Oatmeal? What is the difference in processing?

- Steel Cut Oats Steel-cut oats are whole oat kernels cut into small chunks rather than being smashed flat as in oatmeal. This gives the oats more of a chew texture and also slows both cooking time and digestion time. That means that they have a lower glycemic index and are thus preferable for increasing satiety, lowering the insulin response to the meal, and keeping blood sugar levels from peaking. This also results in delaying hunger so a person is less likely to snack or get overly hungry before the next meal. Here is how I like to cook oats for breakfast. Ingredients 1/2 cup Dry steel cut oats 1 cup Water (You may want a little more than a cup, experiment to your liking) 2 T Raisins (optional or replace with chopped dried apricots etc.) 2 T Ground flax meal (optional, but high in healthy n-3 fatty acids and fiber) Salt to your taste (try Lite salt to lower sodium intake) 2T Sunflower seeds or almonds 1 cup Fresh berries or a banana Directions Heat water to a boil. While water is heating, add the salt, raisins, and flax meal. When the water boils, add the steel cut oats. Stir once. Turn heat down to simmer and cook covered for 7-8 minutes. Provides two small servings. Double for large servings or small servings for 4 people. Serve and eat while hot. Add soy milk or low fat milk. Slice fresh fruit on top to add extra flavor. My wife likes banana slices. I like fresh berries, peaches, or sugar free applesauce. For extra crunch sprinkle almonds or sunflower seeds on top.

Send your message to us

Pre-painted Aluzinc Steel Coil Used for Industry with Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords