Pre-painted Aluzinc Steel Coil Used for Industry with A Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

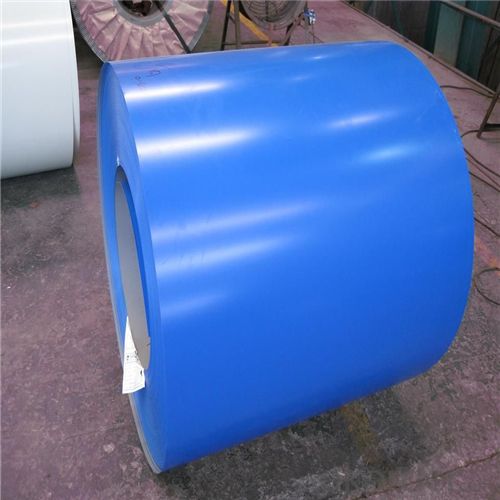

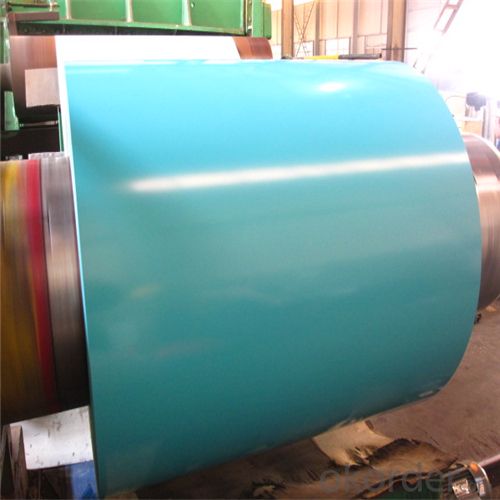

Pre-painted Aluzinc Steel Coil Used for Industry

1.Structure of Pre-painted Aluzinc Steel Coil Description

With aluzinc steel as base metal, after degrease and chemical treatment and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted aluzinc steel. Pre-painted aluzinc steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of Pre-painted Aluzinc Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

3. Pre-painted Aluzinc Steel Coil Images

4. Pre-painted Aluzinc Steel Coil Specification

Pre-painted Aluzinc Steel Coil | |

Thicknenss | 0.18mm-1.5mm |

Width | 900-1250mm |

Coating mass | 30-185g/㎡ |

Paint | PE, PVDF, PU |

Color | RAL Scale |

Coil weight | 3-7mt |

Coil inner diameter | 508 or 610mm |

5.FAQ of Pre-painted Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

Sincerely welcome to contact us for the future details if any item interest you ,and we will make every effort to assure that your requirements will be satisfied ,and we hope to establish long-term business relations with you on the basis of the equality and mutual benefit.

We are waiting for your email.

- Q: How are steel coils used in the manufacturing of tools and equipment?

- Steel coils are used in the manufacturing of tools and equipment as they provide a versatile and durable material for construction. These coils are typically shaped, cut, and molded into various components such as blades, shafts, and handles, which are then assembled to create the final product. The strength and resilience of steel make it an ideal choice for tools and equipment, ensuring longevity and optimal performance in various industries.

- Q: How are steel coils used in the packaging industry?

- Steel coils are used in the packaging industry primarily for the production of metal strapping and seals. These coils are unwound and processed to create strong and durable strapping materials that are used to secure and bundle various types of packaging, such as boxes, crates, and pallets. The steel coils provide excellent tensile strength and resistance to breakage, making them ideal for ensuring the safe transportation and storage of goods.

- Q: How do steel coils contribute to the HVAC industry?

- Steel coils are essential components in HVAC systems as they play a crucial role in heat transfer. These coils are used in air conditioning units and refrigeration systems to facilitate the exchange of heat between the air and the refrigerant. The steel coils are designed to efficiently absorb heat from the indoor air and release it outside, enabling effective cooling. They help maintain comfortable indoor temperatures and enhance the overall energy efficiency of HVAC systems.

- Q: How are steel coils protected during storage and transportation?

- Steel coils are protected during storage and transportation through various measures. These include wrapping them with protective materials such as plastic or paper, using wooden or metal cradles to provide support and prevent damage, securing them with steel bands or straps to prevent movement, and storing them in well-ventilated and dry areas to prevent corrosion.

- Q: How are steel coils used in the production of agricultural equipment?

- Steel coils are used in the production of agricultural equipment as they are often shaped and formed into various components such as frames, chassis, and structural parts. These coils provide strength, durability, and stability to the equipment, making it capable of withstanding the demanding conditions and heavy workloads typically associated with agricultural tasks.

- Q: Can steel coils be stored in a corrosive environment?

- Ideally, steel coils should not be stored in a corrosive environment as exposure to corrosive elements can lead to degradation and damage to the steel surface. Corrosion can weaken the structural integrity of the coils and affect their performance. To ensure the longevity and quality of the steel coils, it is best to store them in a dry and non-corrosive environment.

- Q: ive made lots of knives but they are dark and not shiny. how do i polish a knife and make it shiny

- Look for buffing compound at the hardware store. Home depot lowe's od even Wal-mart/ There is a compound for steel and for iron. I t will not make iron real shinny but it will make it look good. This stuff is to be used with a buffing wheel but I have used it on rags and it work great.

- Q: How are steel coils used in the production of automotive engine components?

- Steel coils are used in the production of automotive engine components by being processed and shaped into various parts, such as pistons, crankshafts, and connecting rods. The coils are first cut, stamped, and formed into the desired shapes, and then undergo heat treatment and other machining processes to enhance their strength and durability. These components are crucial for the proper functioning of an automotive engine, as they provide structural support and help convert the energy generated by the combustion process into mechanical motion.

- Q: How do steel coils compare to stainless steel coils?

- Steel coils and stainless steel coils are both used in various industries, but they differ in their composition and properties. Steel coils are typically made from carbon steel, which is strong and durable but susceptible to corrosion. On the other hand, stainless steel coils are made from an alloy of iron, chromium, and other elements, which provides them with excellent corrosion resistance. Stainless steel coils also have a higher resistance to heat and oxidation, making them suitable for applications that require superior durability and hygiene standards. Overall, stainless steel coils are generally considered to be of higher quality and more suitable for applications where corrosion resistance is crucial.

- Q: How are steel coils used in the manufacturing of metal structures?

- Steel coils are commonly used in the manufacturing of metal structures as they provide a convenient and efficient way to shape and form various components. These coils are unrolled and then processed through machinery that cuts, bends, and shapes the steel into the desired size and shape. This allows for precise and consistent fabrication, making it easier to assemble and construct metal structures such as buildings, bridges, and machinery.

Send your message to us

Pre-painted Aluzinc Steel Coil Used for Industry with A Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords