Color Aluminum Sheets With Mapp Gas for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

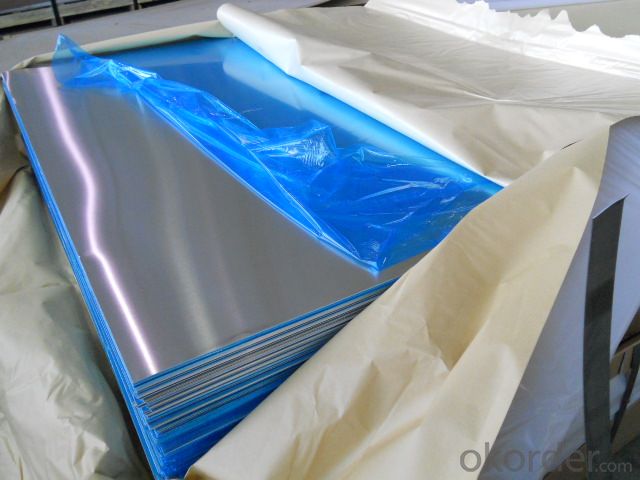

1.Structure of Plain Aluminium Sheets for Different Usages

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminum Sheets are widely used in curtain walls, roofing, decoration, boats, airframes, instrument panels, etc.

2.Main Features of Plain Aluminium Sheets for Different Usages

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

3. Plain Aluminium Sheets for Different Usages Images

4.Specification of Plain Aluminium Sheets for Different Usages

Alloy | AA1050,AA1060, AA1070, AA1100 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-500mm |

Width: | 10mm- 2200mm |

Standard: | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

5.FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put orderin production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium Coils?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: What is the typical impact strength of aluminum sheets?

- The typical impact strength of aluminum sheets can vary depending on the alloy and temper of the material. However, in general, aluminum sheets have a relatively low impact strength compared to other metals. This is because aluminum is a lightweight material that is not as strong or durable as steel or other alloys. The impact strength of aluminum sheets is typically measured in terms of the energy required to cause the material to fracture or deform. This can be expressed in units such as joules or foot-pounds. While specific values may vary, aluminum sheets generally have an impact strength ranging from 10 to 40 joules or 7 to 30 foot-pounds. It is important to note that the impact strength can be influenced by factors such as thickness, surface condition, and the presence of any surface treatments or coatings. Therefore, it is recommended to consult the manufacturer's specifications or conduct specific tests to determine the impact strength of a particular aluminum sheet.

- Q: Could copper wire be welded with aluminum sheet?

- Copper wire could be welded with aluminum sheet, and it needs to use low temperature welding method, if copper wire is in the unit of millimeter and aluminum sheet is also in the unit below 1 mm, you can use electric soldering iron to heat it as hybrid welding and choose low temperature welding materials, you can use WEWELDING M51 welding wire and M51-F flux to complete welding. As for the large aluminum sheet, you can take liquefied gas multihole lance as heat source, then choose the same low temperature materials as welding materials, you can use WEWELDING M51 welding wire and M51-F flux to complete welding. Welding fundamentals of these two welding methods: both of them are use heatable heat source to heat the matrix to 179 degree, the melting point of WEWELDING M51, then use matrix’s heat conduction to melt welding wire, completing welding. The process of melting welding wire is the process of smearing the welding wire with flux into welding area, melting welding wire completely depends on matrix’s heat conduction.

- Q: Can the aluminum sheets be used for manufacturing musical instruments?

- Musical instruments can indeed be manufactured using aluminum sheets. Aluminum, being a lightweight and versatile material, offers numerous advantages in instrument manufacturing. Its exceptional sound transmission properties are well-known, making it ideal for producing resonant and lively tones in musical instruments. Furthermore, aluminum boasts high durability and resistance to corrosion, ensuring the longevity of the instruments. Aluminum sheets are frequently used in the production of percussion instruments such as cymbals and bells due to their ability to generate clear and melodious sounds. Additionally, aluminum can be easily shaped and formed into different components, making it a popular choice for constructing brass instruments like trumpets and trombones. In conclusion, aluminum sheets are a viable and successful option in the manufacturing of musical instruments.

- Q: Can the aluminum sheets be used for manufacturing heat exchanger fins?

- Indeed, the utilization of aluminum sheets is possible in the production of heat exchanger fins. Owing to its remarkable thermal conductivity and resistance to corrosion, aluminum stands as a frequently employed substance in heat exchangers. The lightweight and easily malleable attributes of aluminum sheets render them exceptionally suitable for the creation of fins that possess an extensive surface area, thereby augmenting heat transfer. Furthermore, aluminum is readily accessible and cost-efficient, solidifying its status as a favored selection within the realm of heat exchanger manufacturing.

- Q: what is better for my 96 mustang gt. porting and polishing my stock heads or getting aluminum heads. also could i do a 3v conversion?

- Aluminum. They reduce weight and reduce heat!

- Q: How to mix solid aluminium sheet with solid copper sheet (using heat?) to make a compound.

- Aluminium and copper can be used to produce an alloy (see the first link, under wrought alloys). The alloy strength is comparable to steel. Aluminium melts at around 660C and copper at 1084C, so you'd need special burners to produce that kind of heat. An oxyacetylene torch would do it, but more readily available gases like propane and butane mixed with air would also suffice.

- Q: Can 101 aluminum sheets be recycled?

- Yes, 101 aluminum sheets can be recycled. Aluminum is highly recyclable, and the recycling process for aluminum is quite efficient. By recycling aluminum sheets, valuable resources can be conserved, energy can be saved, and greenhouse gas emissions can be reduced. Recycling aluminum also helps in reducing landfill waste and the need for mining new aluminum ores. Therefore, it is recommended to recycle 101 aluminum sheets to contribute to a more sustainable and environmentally friendly future.

- Q: What are the different grades of aluminum sheets?

- There are several different grades of aluminum sheets available in the market, each with its own unique properties and uses. The most commonly used grades include 3003, 5052, and 6061. - Grade 3003: This is a non-heat treatable alloy that is highly resistant to corrosion. It is often used in applications where corrosion resistance is essential, such as in packaging, cooking utensils, and chemical equipment. - Grade 5052: This grade is also non-heat treatable and offers excellent corrosion resistance. It is known for its strength and durability, making it suitable for marine applications, transportation equipment, and architectural purposes. - Grade 6061: This is a heat treatable alloy that combines good corrosion resistance with high strength. It is widely used in structural applications, such as in aircraft components, automotive parts, and construction materials. Apart from these grades, there are also other specialized aluminum alloys available, such as 2024, 7075, and 5083, which offer specific properties for particular industries or applications. It is important to consider the specific requirements of your project before choosing a grade of aluminum sheet, as each grade has its own strengths and limitations. Consulting with a knowledgeable supplier or expert can help you determine the most suitable grade for your needs.

- Q: What types of aluminum sheets are recommended for outdoor applications due to their durability and resistance to weather conditions?

- <p>Yes, there are specific types of aluminum sheets designed for outdoor use. Marine-grade aluminum sheets, such as 5083 or 5086 alloys, are highly resistant to corrosion and are ideal for marine applications. Aluminum sheets with a protective coating, like anodized aluminum or those with a fluoropolymer finish, offer excellent weather resistance and durability. Additionally, aluminum sheets with a mill finish or those coated with a clear coating can also be suitable for outdoor use due to their resistance to UV rays and ability to withstand temperature fluctuations.</p>

- Q: How do you determine the thickness tolerance of an aluminum sheet?

- To ascertain the thickness tolerance of an aluminum sheet, one must take into account several factors. Initially, it is crucial to refer to the industry standards and specifications for aluminum sheets. These standards typically offer guidelines and tolerances for different thicknesses of aluminum sheets, which can vary depending on the specific alloy and grade of the material. Subsequently, it becomes essential to utilize precise measuring equipment such as calipers or micrometers to precisely measure the thickness of the aluminum sheet. Multiple measurements should be taken at various locations on the sheet to account for any potential discrepancies. Once the measurements are acquired, they should be compared to the specified thickness tolerance provided by the industry standards. The tolerance generally represents the acceptable range in which the actual thickness of the sheet can deviate. For instance, if the specified thickness tolerance is ±0.002 inches, it signifies that the sheet's thickness can vary within this range. If the measured thickness falls within the specified tolerance range, the sheet is deemed to be within tolerance. However, if the measured thickness exceeds the upper or lower limit of the tolerance range, it indicates that the sheet is out of tolerance and may not meet the required specifications. In certain instances, it may be necessary to consult with the aluminum sheet's manufacturer or supplier to determine the specific tolerance requirements for a particular application. They can offer additional information and guidance regarding the appropriate thickness tolerance to ensure the sheet fulfills its intended purpose. All in all, the determination of the thickness tolerance of an aluminum sheet involves adhering to industry standards, employing accurate measuring equipment, and comparing the measured thickness to the specified tolerance range. This process guarantees that the sheet meets the required specifications and can be effectively utilized in diverse applications.

Send your message to us

Color Aluminum Sheets With Mapp Gas for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords