Aluminum Colors Sheets for Decorative Ceiling System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Decorative Aluminum Alloy Sheets for Ceiling System

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Decorative Aluminum Alloy Sheets for Ceiling System

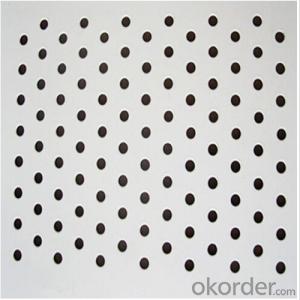

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Decorative Aluminum Alloy Sheets for Ceiling System

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

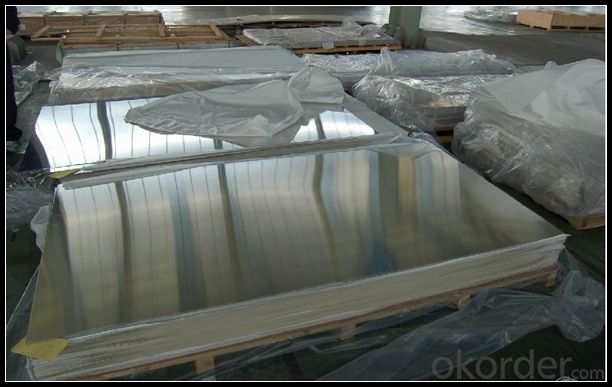

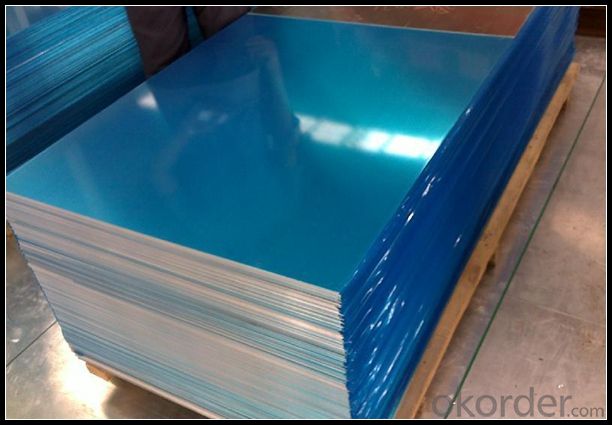

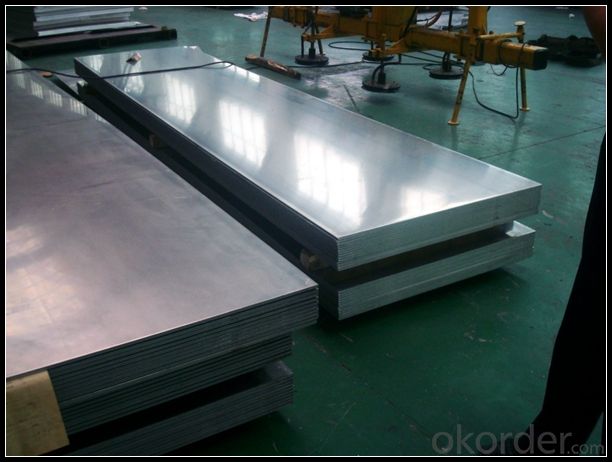

5. Image of Decorative Aluminum Alloy Sheets for Ceiling System

6. Package and shipping of Decorative Aluminum Alloy Sheets for Ceiling System

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum sheets prone to warping?

- Yes, aluminum sheets are prone to warping, especially when exposed to high temperatures or subjected to excessive pressure. However, the extent of warping depends on various factors such as the thickness of the sheet, the specific alloy used, and the conditions it is exposed to.

- Q: Can I bake falafel patties in the oven using an aluminum foil on top of the pan I am using to put in the oven? Will the aluminum foil catch fire in the oven? Also, if I put the aluminum foil I wouldn't have to grease up the foil with oil...the patties just wont stick to aluminum foil right?

- Aluminum foil is just the metal called aluminum which has been pressed into a very thin sheet (foil), and metals won't melt or catch fire here and there till they get extremely hot (in huge furnaces). A home oven is waaay too cool for that. As for sticking, that depends on whether the foil is touching your patties and how much, as well as which ingredients you used in the patties since some will carmelize or dry out onto the foil but only where they contacted. You can always tent or make a dome with the foil so it doesn't touch any of the food though if you're concerned. Not sure why you'd be covering falafels though, since that will steam them (at least partly) not bake, them and therefore not create a crispy exterior.

- Q: Are aluminum sheets suitable for marine applications?

- Indeed, aluminum sheets prove to be a fitting option for marine applications. Owing to its exceptional resistance to corrosion and durability in marine settings, aluminum emerges as a widely employed material in the maritime sector. Notably, its lightweight yet robust nature renders it an ideal selection for diverse purposes, encompassing boat construction, ship hulls, decks, and other marine structures. Moreover, aluminum boasts a commendable strength-to-weight ratio, thereby enhancing fuel efficiency and reducing operational expenses. Its capacity to endure the harsh conditions of saltwater, coupled with its minimal maintenance requirements, further solidifies its popularity in marine applications. All in all, aluminum sheets serve as a dependable and efficient material for employment in the marine industry.

- Q: Are aluminum sheets suitable for food processing applications?

- Yes, aluminum sheets are suitable for food processing applications. Aluminum is a popular choice for food processing due to its excellent properties such as corrosion resistance, thermal conductivity, and low reactivity with food substances. These sheets are commonly used in various food processing equipment including storage containers, cooking utensils, and packaging materials. Aluminum sheets are easy to clean, lightweight, and have good heat distribution properties, making them ideal for applications that require precise temperature control during food processing. Additionally, aluminum is a non-toxic material, ensuring food safety and preventing any potential contamination. Overall, aluminum sheets are a reliable and widely used material in the food processing industry.

- Q: What are the different methods of surface preparation for aluminum sheet?

- The different methods of surface preparation for aluminum sheet include chemical cleaning, mechanical abrasion, and etching. Chemical cleaning involves the use of a cleaning solution to remove dirt, grease, and other contaminants from the surface. Mechanical abrasion uses techniques such as sanding or wire brushing to physically remove any loose or oxidized material. Etching is a process that involves applying an acidic solution to the surface to create a rough texture, which improves the adhesion of subsequent coatings or finishes.

- Q: im wondering what happens if you MIG weld aluminum with the correct wire but without using a shielding gas? Would it just be extremely messy or does there HAVE to be an inert gas flowing for it to bond?thanks

- Mig Welding Aluminum Without Gas

- Q: Can aluminum sheets be used for sign making?

- Yes, aluminum sheets can be used for sign making. Aluminum is a commonly used material for making signs due to its durability, lightweight nature, and resistance to rust and corrosion. It is a versatile material that can be easily cut, shaped, and printed on, making it suitable for various sign making applications.

- Q: is steel better for making bicycle frames.....how does it differ from the aluminum framed bikes?

- Unless you are an all star pro, a steel bike will suit you fine. Thing is, the difference in weight is so small that unless you are racing people in multi-national competitions, it's just a lot of extra money you could put into buying a REALLY nice steel frame. Don't let ads fool you, steel are just as good as aluminum.

- Q: Are aluminum sheets resistant to abrasion?

- Yes, aluminum sheets are generally resistant to abrasion. Aluminum is known for its durability and strength, making it resistant to scratches or damage caused by abrasion. However, the level of resistance may vary depending on the specific alloy and thickness of the aluminum sheet. Thicker sheets with higher alloy content tend to provide better resistance against abrasion. Additionally, the surface finish of the aluminum sheet can also play a role in its resistance to abrasion. Overall, aluminum sheets are a reliable choice when it comes to withstanding abrasion in various applications.

- Q: Do you use aluminum alloy boards or aluminum plates for outdoor billboards?

- Pure aluminum density (P =2.7g/cm3), iron is about 1/3, the low melting point (660 C), aluminum is face centered cubic structure, so it has high plasticity (delta psi:: 32~40%, 70~90%), easy processing, can be made into various sections and plates. The corrosion resistance is good; but pure aluminum strength is very low, the annealed state sigma B is about 8kgf/mm2, it is not as a structural material. Through the long-term production practice and scientific experiments, people gradually to join the alloying elements and the use of heat treatment to strengthen aluminum, which has been a series of Aluminum Alloy. Adding alloy elements to form certain can with high strength in keeping advantages of pure aluminum etc. at the same time, a b value can reach 24 ~ 60kgf/mm2. so that its "strength" (strength and the ratio of the proportion of b/ sigma rho) more than a lot of steel structure become an ideal material, widely used in machinery manufacturing, transport Machinery, power machinery and aviation industry, aircraft fuselage, skin, compressor and so on, often made of aluminum alloy, in order to reduce the weight. Using aluminum alloy instead of steel plate welding, the structure weight can be reduced by more than 50%

Send your message to us

Aluminum Colors Sheets for Decorative Ceiling System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords