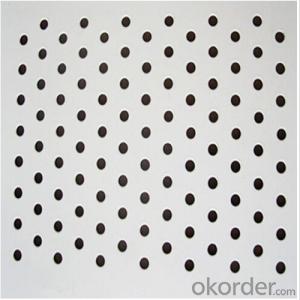

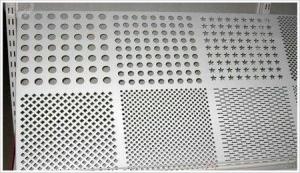

Decorative Aluminum Foil Sheets With Holes for Ceiling System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

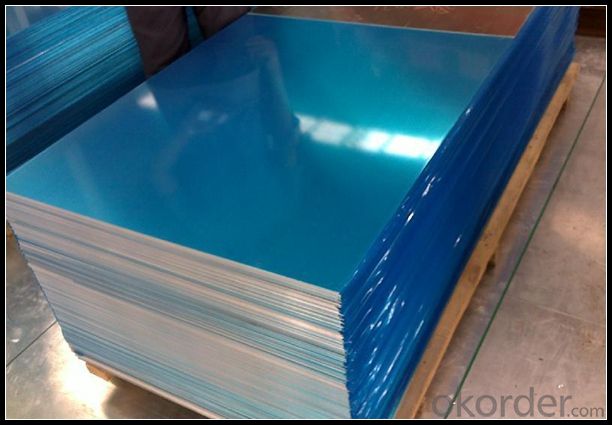

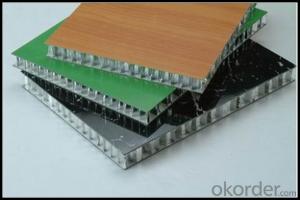

1.Structure of Decorative Aluminum Sheet for Ceiling System

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Decorative Aluminum Sheet for Ceiling System

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

3. Decorative Aluminum Sheet for Ceiling System Images

4.Specification of Decorative Aluminum Sheet for Ceiling System

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: What is the best way to paint over aluminium siding? Should it be primed? What type of prime should be used? What type of paint should be used on this surface? What brush or roller should be used to apply the paint?

- Two good answers above me, but I do want to add that aluminum siding will chalk on the outside. Definetely needs to be power washed, preferably with TSP (Tri Sodium Phosphate). That will get the metal totally clean to give it good tooth for the prime and paint. As said above, you need an aluminum prime, which is not a problem. Any paint store, Home Depot or Loews in the paint department can lead you to the right prime. Just make sure you are using the corresponding paint for your prime. Anyone can slap on a coat of paint, but when you do the groundwork first, you will have a paint job that will look like new for many years. I hope this helps you.

- Q: Are aluminum sheets suitable for chemical reactors?

- Yes, aluminum sheets can be suitable for chemical reactors depending on the specific application and conditions. Aluminum is known for its excellent corrosion resistance, especially when exposed to air or water, due to the formation of a protective oxide layer. This makes it suitable for many chemical reactions that involve non-aggressive substances. However, it is important to note that aluminum may not be suitable for reactors that handle highly acidic or alkaline solutions, as these can corrode the oxide layer and lead to degradation of the metal. Additionally, aluminum may react with certain chemicals, such as strong oxidizers, halogens, or strong bases, which could compromise the integrity of the reactor. In cases where aluminum is used in chemical reactors, it is common to employ protective coatings or linings to enhance its resistance to corrosion and chemical reactions. These coatings can provide an additional barrier between the aluminum and the reactants, ensuring a safe and effective operation. Ultimately, the suitability of aluminum sheets for chemical reactors depends on the specific chemical reactions, operating conditions, and the necessary level of corrosion resistance. It is always advisable to consult with experts and consider the compatibility of materials before selecting aluminum for such applications.

- Q: Is it suitable to use aluminum sheets in environments with high moisture levels?

- <p>Yes, aluminum sheets can be used in areas with high humidity. Aluminum is a corrosion-resistant metal that does not rust, making it suitable for humid environments. However, it's important to ensure that the aluminum is properly coated or anodized to protect it from potential damage due to moisture. This treatment can prevent any form of corrosion and extend the life of the aluminum sheets.</p>

- Q: I need to know what composite bats do and how (or if) they are better than aluminum bats.

- Aluminum Bats Vs Composite Bats

- Q: Can aluminum sheets be used for solar panel frames?

- Yes, aluminum sheets can be used for solar panel frames. Aluminum is a popular choice for solar panel frames due to its excellent strength-to-weight ratio, corrosion resistance, and durability. These characteristics make it a suitable material for supporting and protecting solar panels, which are typically installed in outdoor environments. Aluminum frames provide structural stability and ensure the longevity of solar panels by protecting them from environmental factors such as wind, rain, and snow. Additionally, aluminum is easily recyclable, making it an environmentally friendly choice for solar panel frames.

- Q: What advantages does the ceramic panel curtain wall have compared with the aluminum sheet and stone curtain wall?

- Metal plate curtain wall deformation resistance is poor, the plate strength and steel are not high enough, waterproof sealing performance is not good enough, easy to fade, deformation, also can cause light pollution. Construction and installation technical requirements are relatively high.Stone curtain wall is now used most, but more stereotyped, and negative news constantly, stone fell, heavy stones, high-rise building exterior wall of high risk, poor fire performance.

- Q: To an idiot, this may seem like a stupid question: its just aluminum. But it may not be.However seeing that I am only a high school student and don't have access to aluminum power (which is what I desire for an independent experiment) so I'd like to grind consumer grade aluminum foil down bases of Mohs scale of Hardness.My concern is that aluminum foil is Aluminum oxide which is a 9 (10 being diamond, 1 being talcum powder) and this would be horribly difficult to grind.If it is Alumina, that's only a 3.5.If it does happen to be aluminum oxide, can you think of a way to remove the Oxygen. Would nitric acid work.

- Aluminum foil, Commonly known as Shiny Metal Paper is actually made of Gold. The shiny side has wax on it to make it shinier, while the duller side is coated in a light dusting of diamond powder. This could be ground in a coffee machine, but I don't reccomend drinking the product of the blending. Do not microwave. Thx! Don't forget to rate best answer!

- Q: How do you achieve a mirror-like finish on aluminum sheets?

- To achieve a mirror-like finish on aluminum sheets, a multi-step process is usually followed. First, the sheets are thoroughly cleaned and degreased to remove any dirt or oils. Then, they are sanded with progressively finer grits of sandpaper to smooth out any imperfections. Next, a polishing compound is applied and buffed onto the surface using a rotating wheel or by hand. This step is repeated with finer and finer compounds until the desired level of shine is achieved. Finally, a protective coating might be applied to maintain the mirror-like finish.

- Q: What is the fatigue life of aluminum sheets?

- The fatigue life of aluminum sheets refers to the number of cycles that the material can withstand before failure occurs under cyclic loading conditions. The fatigue life of aluminum sheets can vary depending on various factors such as the alloy composition, thickness, surface finish, loading conditions, and environmental factors. Aluminum is known for its relatively high fatigue strength compared to other materials, making it a popular choice in various industries including aerospace, automotive, and construction. The fatigue life of aluminum sheets is typically influenced by the presence of microstructural defects such as inclusions, voids, and grain boundaries. To determine the fatigue life of aluminum sheets, fatigue tests are conducted using standardized procedures such as ASTM E466 or ASTM E606. These tests involve subjecting the material to cyclic loading conditions, typically at a constant stress or strain amplitude, while monitoring the number of cycles required for failure to occur. The results are then used to generate an S-N curve, which represents the relationship between the applied stress or strain amplitude and the number of cycles to failure. The S-N curve provides valuable information about the fatigue life of aluminum sheets, indicating the stress or strain levels at which the material can withstand a certain number of cycles before failure. It is important to note that the fatigue life of aluminum sheets can be improved through various methods such as alloying, heat treatment, surface treatment, and proper design considerations. In conclusion, the fatigue life of aluminum sheets is a critical factor to consider when designing components or structures subjected to cyclic loading conditions. Understanding the specific properties and characteristics of the aluminum alloy, along with proper testing and analysis, can help determine the fatigue life and ensure the safe and reliable performance of aluminum sheets in various applications.

- Q: Can aluminum sheets be etched or engraved?

- Yes, aluminum sheets can be etched or engraved.

Send your message to us

Decorative Aluminum Foil Sheets With Holes for Ceiling System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords