Colored Aluminum Foil Sheets for Aluminium Window and Door Profile/Extrusions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Window and Door Profile/Extrusions Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Window and Door Profile/Extrusions:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

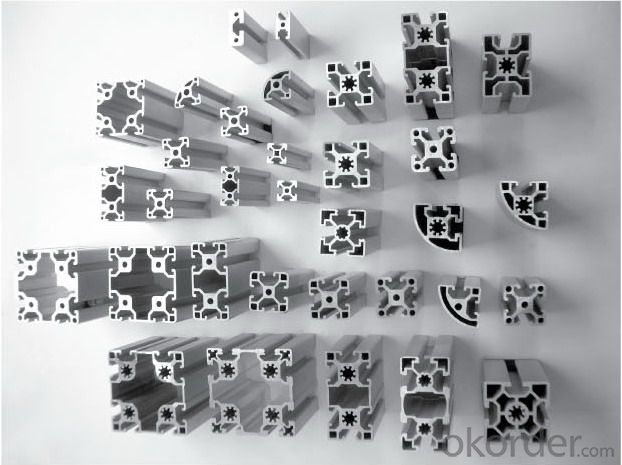

3.Aluminium Window and Door Profile/Extrusions Images:

4.Aluminium Window and Door Profile/ExtrusionsSpecification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

① How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Do 101 aluminum sheets have any specific sound or vibration damping properties?

- 101 aluminum sheets possess specific properties that contribute to sound and vibration damping. Aluminum is renowned for its impressive damping characteristics, enabling it to effectively absorb vibrations and decrease noise levels. This is attributed to its high density and stiffness, which facilitate the dissipation of vibrational energy. Moreover, the sound and vibration damping properties of aluminum sheets can be enhanced through the application of coatings or treatments designed for sound-damping purposes. These treatments may include adhesive-backed damping sheets or constrained layer damping materials. By incorporating such treatments, the sound and vibration damping capabilities of 101 aluminum sheets can be further improved. Consequently, these sheets are widely utilized in industries where noise reduction and vibration control play crucial roles, such as automotive, aerospace, and construction.

- Q: Are aluminum sheets easy to clean?

- Yes, aluminum sheets are generally easy to clean due to their smooth surface and non-porous nature, allowing for easy removal of dirt, grease, and stains with regular cleaning agents.

- Q: Is it suitable to use aluminum windows in areas with cold weather conditions?

- <p>Yes, you can use aluminum windows in cold climates, but there are considerations. Aluminum is a good conductor of heat, which can lead to heat loss in cold weather. To mitigate this, insulated glass units and thermally broken frames can be used. These designs slow down heat transfer, making aluminum windows more energy-efficient in cold climates. Additionally, proper sealing and weatherstripping are crucial to prevent drafts and ensure the windows perform well in low temperatures.</p>

- Q: What are the common uses of aluminum sheets?

- Aluminum sheets possess excellent properties, rendering them highly versatile and extensively utilized across various industries. Their applications encompass: 1. Construction: In the construction industry, aluminum sheets find common usage for roofing, siding, and insulation purposes. Their lightweight nature, durability, and resistance to corrosion make them ideal for shielding against the elements. 2. Transportation: The automotive and aerospace industries heavily rely on aluminum sheets. These sheets contribute to the manufacturing of car bodies, truck trailers, and aircraft parts owing to their impressive strength-to-weight ratio. Consequently, the utilization of aluminum sheets aids in enhancing fuel efficiency and reducing overall vehicle weight. 3. Packaging: Aluminum sheets serve as a popular choice for packaging purposes, specifically within the food and beverage industry. Cans, foils, and containers are frequently crafted from aluminum sheets, as they effectively safeguard packaged products by acting as barriers against moisture, light, and oxygen. 4. Electrical and Electronics: The electrical and electronics industry benefits from the application of aluminum sheets due to their exceptional conductivity. Their utilization extends to the manufacturing of electrical enclosures, heat sinks, and wiring, as they efficiently dissipate heat and protect delicate electronic components. 5. Marine Industry: Aluminum sheets hold significant value within the marine industry due to their resistance to corrosion. They are employed in the construction of boat hulls, ship fittings, and other marine equipment. The ability of aluminum sheets to withstand harsh marine environments, alongside their lightweight properties, renders them an appealing choice. 6. Decorative Applications: Architectural applications often feature aluminum sheets for their aesthetic appeal. These sheets can be effortlessly shaped, formed, and colored to create diverse decorative elements like wall cladding, ceilings, and decorative panels. In conclusion, aluminum sheets serve as a fundamental material across numerous industries, including construction, transportation, packaging, electrical and electronics, marine, and decorative applications. Their versatility and significance are evident in their widespread utilization throughout various sectors.

- Q: Can aluminum sheets be used for packaging?

- Yes, aluminum sheets can be used for packaging. Aluminum is a versatile and widely used material in the packaging industry due to its numerous advantageous properties. It is lightweight, strong, durable, and resistant to corrosion, making it an ideal choice for packaging applications. Aluminum sheets can be easily formed into various shapes and sizes, providing flexibility in design and customization. Additionally, aluminum is impermeable to light, moisture, gases, and microorganisms, ensuring the preservation and protection of the packaged goods. It is also a good conductor of heat, which allows for efficient heat transfer during processes like sterilization or pasteurization. Furthermore, aluminum is recyclable, making it an environmentally friendly packaging option. Overall, aluminum sheets are an excellent choice for packaging due to their excellent properties and versatility.

- Q: im wanting to try and source my own chemicals for experiments and such in the cheapest way possiblei thought a cheap method of making powdered aluminium would be to just sandpaper aluminium kitchen foil and collect the powder, what i need to know is:how pure is aluminium foil?.....e.g is it actually mixed with some other metals and is an alloyand will the powder i collect be as good as bottled aluminium powder? i know it wont be perfect but as long as its similar that should be fineim using it for pyrotechnical experiments by the way

- Aluminum foil is pretty pure for most purposes (99.1 % pure). However, I really think sandpapering aluminum foil is not your best option. For one, aluminum foil is quite expensive, I wonder if you could just get a bunch of the powder for a cheaper price than buying an equal mass of aluminum foil. Also, how would you even begin sandpapering it? If you rub a crumpled up ball of aluminum on a rough surface, you don't get a powder, you just get a ripped up ball and a gray mark on the rough surface. But you could try, tell me if it works. However, I think you may have better odds with aluminum cans. They are cheaper and thicker thus not so prone to ripping. Although I still doubt you could get a reasonable quantity of aluminum powder from that. If all else fails, you could always try stuffing a bunch of aluminum foil in a blender.

- Q: For example, in hydrangeas, when aluminum reacts with the anthocyanins in the flower's petals, the hydrangeas turn blue, but what chemical reaction occurs?

- Two factors affect the color in Hydrangea macrophylla cultivars: soil acidity and the presence of aluminium in the soil. To obtain a blue hydrangea, aluminum must be present in the soil. The pH of the soil should be low (4 - 4.5). In alkaline soil aluminium is tied up. The plants are unable to absorb the existing aluminium and the flowers will not bloom blue. Also, when aluminium in the soil is used up the flower color will be red or pink again. If the soil is watered with aluminium salts aluminium is accumulated in the petals and the color turns blue. Only red and pink colored Hortensis are suitable for the breeding of blue flowers. They contain the dye component delphinidin. At the end of this site you find explanation and the formula: www.uni-regensburg.de/Fakultaeten...

- Q: Can 101 aluminum sheets be recycled?

- Certainly, it is possible to recycle 101 aluminum sheets. Aluminum possesses a remarkable recyclability, boasting an impressively efficient recycling procedure. Through the act of recycling aluminum sheets, we not only preserve valuable resources but also conserve energy and diminish greenhouse gas emissions. Additionally, recycling aluminum aids in the reduction of landfill waste and curtails the necessity for fresh aluminum ore mining. Consequently, we highly recommend recycling 101 aluminum sheets to actively contribute towards a future that is more sustainable and environmentally conscious.

- Q: This question asks for methods to determine the thickness of aluminum sheets.

- <p>To measure the thickness of aluminum sheets, you can use various methods including mechanical thickness gauges, ultrasonic thickness gauges, or calipers. Mechanical gauges are simple and involve sliding a foot along the sheet until it bottoms out on both sides. Ultrasonic thickness gauges use sound waves to measure thickness and are non-destructive, providing accurate measurements. Calipers can also be used for manual measurement, though they may be less precise for very thin sheets. Always ensure the measuring device is calibrated and suitable for the material and thickness range of the aluminum sheet in question.</p>

- Q: What are the different manufacturing methods for aluminum sheets?

- There are several different manufacturing methods for aluminum sheets, each with its own unique characteristics and applications. 1. Rolling: The most common method of manufacturing aluminum sheets is through rolling. In this process, large slabs of aluminum are passed through a series of rollers, which reduce the thickness of the slab and increase its length. This method can produce sheets with consistent thickness and excellent surface finish. 2. Extrusion: Extrusion is another method used to manufacture aluminum sheets. In this process, a heated billet of aluminum is forced through a die, resulting in a continuous length of sheet. Extrusion allows for complex shapes and profiles to be created, making it suitable for applications such as building construction and automotive components. 3. Casting: Casting involves pouring molten aluminum into a mold and allowing it to cool and solidify into a sheet shape. This method is often used for producing thicker sheets or sheets with specific alloy compositions. Casting can offer unique properties and is commonly used in industries such as aerospace and defense. 4. Cladding: Cladding is a process where a thin layer of aluminum is bonded to another material, such as steel or composite materials. This method combines the desirable properties of aluminum, such as corrosion resistance and lightweight, with the strength and durability of the base material. Clad aluminum sheets are commonly used in construction, transportation, and electrical industries. 5. Powder metallurgy: Powder metallurgy involves the formation of aluminum sheets from powdered aluminum particles. The powder is compacted into a desired shape and then sintered at high temperatures to fuse the particles together. This method is used for producing complex shapes and can provide improved mechanical properties. Each manufacturing method for aluminum sheets has its own advantages and disadvantages, depending on the desired properties, application, and cost considerations. Therefore, it is important to carefully select the most appropriate method based on the specific requirements of the project.

Send your message to us

Colored Aluminum Foil Sheets for Aluminium Window and Door Profile/Extrusions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords