Orange Pattern Embossed and PE Painted Aluminum Coils

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

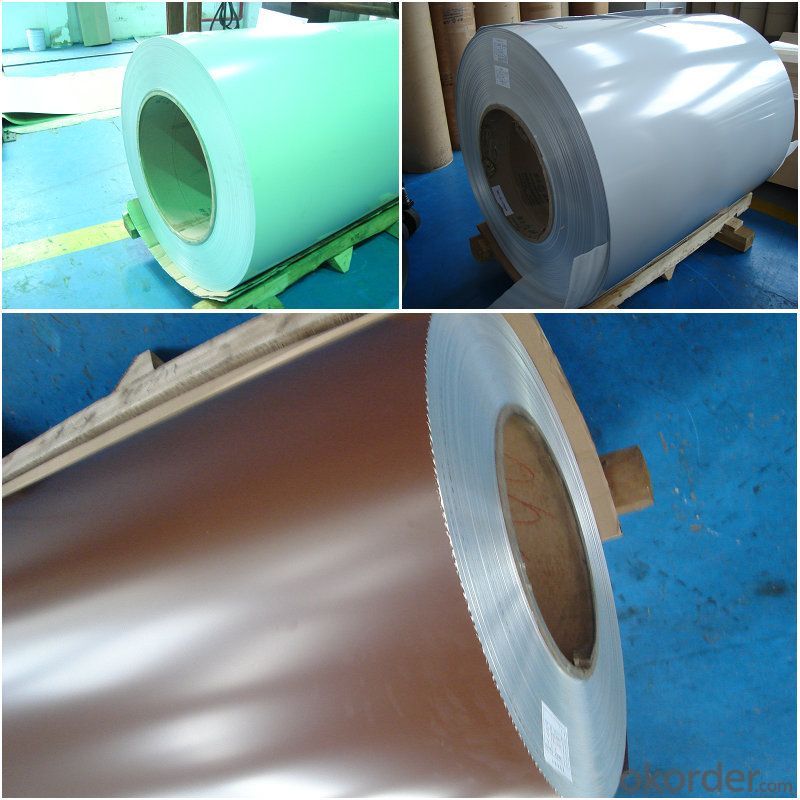

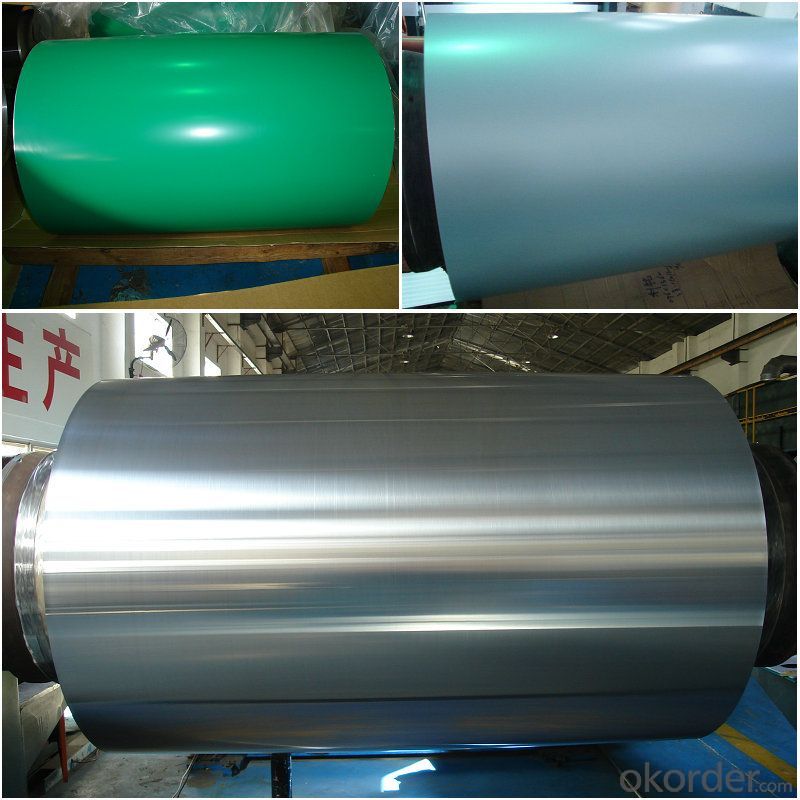

1.Structure of Orange Pattern Embossed and PE Painted Aluminum Coils

We professionally produce stucco embossed and coated aluminum coils, which are widely used in refrigerators, ice-boxes, cold storage, freezer, etc.

Stucco embossed and coated aluminum sheets look more beautiful and better at strength and rigidity than normal aluminum coils.

We normally use 3105, H44 as base coils. Specification of our stucco embossed and color coated aluminium coils: thickness 0.2-0.6mm, width less than 1600mm. As for coating, we normally use PVDF coating, PE coating, etc. We can adjust coating as per customers’ requirements.

2. Main Features of Orange Pattern Embossed and PE Painted Aluminum Coils

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

3. Orange Pattern Embossed and PE Painted Aluminum Coils Images

4. Specification of Orange Pattern Embossed and PE Painted Aluminum Coils

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:How does the surface finish affect the optical properties of aluminum sheet?

- The surface finish of aluminum sheet can significantly impact its optical properties. A smooth surface finish on aluminum sheet results in better light reflection and less scattering, leading to higher reflectivity. This means that more light is reflected off the surface, making the aluminum sheet appear brighter and more reflective. On the other hand, a rough or textured surface finish on aluminum sheet can cause light to scatter in different directions, reducing reflectivity. This can result in a duller and less reflective appearance. Additionally, the surface finish can affect the appearance of any coatings or films applied to the aluminum sheet. A smooth surface finish allows for better adhesion and uniformity of coatings, enhancing their optical properties. In summary, a smooth surface finish on aluminum sheet enhances its optical properties by increasing reflectivity and reducing scattering, resulting in a brighter and more reflective appearance.

- Q:How does the grain structure of aluminum sheet affect its properties?

- The properties of aluminum sheet are greatly influenced by its grain structure. The arrangement of individual aluminum crystals, or grains, within the sheet is what determines this structure. The size, shape, and orientation of these grains can have an impact on the mechanical and physical properties of the aluminum sheet. For example, the sheet's strength, ductility, hardness, and corrosion resistance can all be affected by the grain structure. When it comes to strength, a fine-grained aluminum sheet tends to be stronger than one with coarse grains. This is because smaller grains result in more grain boundaries, which act as obstacles to the movement of dislocations and make the material more resistant to deformation. On the other hand, a coarse-grained structure has fewer grain boundaries, which leads to reduced strength. Additionally, the ductility of the aluminum sheet is influenced by its grain structure. Sheets with finer grains typically exhibit better ductility because the numerous grain boundaries hinder the motion of dislocations and prevent cracks from spreading. In contrast, coarser grains tend to promote crack propagation, resulting in reduced ductility. The hardness of the aluminum sheet is also affected by its grain structure. In general, a fine-grained structure contributes to higher hardness due to the increased density of dislocations and the strengthening effect of grain boundaries. Conversely, a coarse-grained structure leads to reduced hardness as there are fewer obstacles to dislocation motion. Furthermore, the grain structure plays a role in the corrosion resistance of the sheet. Fine-grained aluminum sheets tend to have better corrosion resistance compared to coarse-grained ones. This is because the presence of more grain boundaries in fine-grained structures impedes the movement of corrosive agents, thus reducing the likelihood of corrosion. In conclusion, the grain structure of aluminum sheet has a significant impact on its properties. Fine-grained structures generally enhance strength, ductility, hardness, and corrosion resistance, while coarse-grained structures tend to have the opposite effects. Therefore, it is crucial to control and optimize the grain structure during the manufacturing process in order to achieve the desired properties of aluminum sheet for different applications.

- Q:What are the standards and certifications available for aluminum sheets?

- There are several standards and certifications available for aluminum sheets, ensuring their quality and compliance with industry requirements. Some of the commonly recognized ones include: 1. ASTM International Standards: The American Society for Testing and Materials (ASTM) has developed a range of standards specifically for aluminum and aluminum alloys. These standards cover various aspects such as chemical composition, mechanical properties, and dimensional tolerances, ensuring consistent quality across different aluminum sheet products. 2. ISO 9001: The ISO 9001 certification is a globally recognized standard for quality management systems. Aluminum sheet manufacturers that are ISO 9001 certified have demonstrated their commitment to meeting customer requirements, continuous improvement, and adherence to strict quality control processes. 3. ASME Standards: The American Society of Mechanical Engineers (ASME) has established specific standards for aluminum sheet materials used in pressure vessels, piping, and other applications. These standards ensure the safety and reliability of aluminum sheets in critical applications. 4. MIL-Specifications: The United States Department of Defense (DoD) has developed military specifications (MIL-Specs) for various materials, including aluminum sheets. These specifications define the requirements for military-grade aluminum sheets, ensuring their suitability for specific defense applications. 5. EN Standards: The European Committee for Standardization (CEN) has developed a series of European Norm (EN) standards for aluminum and aluminum alloys. These standards cover various aspects such as chemical composition, mechanical properties, and surface finishes, ensuring compatibility and consistency across the European market. 6. RoHS Compliance: Restriction of Hazardous Substances (RoHS) compliance is crucial for aluminum sheets used in electrical and electronic equipment. This certification ensures that the aluminum sheets do not contain hazardous substances such as lead, mercury, cadmium, and certain flame retardants, thus guaranteeing their environmental safety. It is important for manufacturers and suppliers of aluminum sheets to comply with these standards and certifications to ensure the highest quality, safety, and suitability of their products for specific applications.

- Q:Can aluminum sheets be used for architectural applications?

- Yes, aluminum sheets can definitely be used for architectural applications. Aluminum is a versatile and lightweight material that offers numerous advantages for architectural projects. Its durability, corrosion resistance, and ability to withstand extreme weather conditions make it ideal for various architectural applications such as roofing, cladding, facades, windows, doors, and decorative elements. Aluminum sheets are available in a wide range of thicknesses, finishes, and colors, allowing architects and designers to achieve their desired aesthetic while maintaining structural integrity. The material can be easily shaped, bent, and formed into complex designs, providing flexibility and creative freedom to architects. In addition to its aesthetic appeal, aluminum is also a sustainable choice for architectural applications. It is a highly recyclable material, with a high recycling rate, making it an environmentally friendly option. Using aluminum sheets in architectural projects can contribute to reducing the carbon footprint and promoting sustainable design practices. Furthermore, aluminum sheets offer excellent thermal and acoustic properties, contributing to energy efficiency and sound insulation in buildings. The material can help reduce energy consumption and enhance occupant comfort, making it an attractive choice for architects and building owners. Overall, aluminum sheets are a popular choice in architectural applications due to their versatility, durability, sustainability, and aesthetic appeal. They offer numerous benefits and can be used in various ways to create stunning architectural designs while ensuring long-lasting performance.

- Q:What is the width and length of the aluminum sheets?

- Depending on the specific product or manufacturer, the aluminum sheets' width and length may differ. To obtain accurate measurements, it is advisable to consult the product specifications or get in touch with the manufacturer.

- Q:Can aluminum sheets be used for water tanks?

- Yes, aluminum sheets can be used for water tanks. Aluminum is a lightweight and corrosion-resistant material, making it suitable for storing water. It is commonly used in industries such as aerospace and marine due to its durability and ability to resist rust and corrosion. Aluminum tanks are also easier to transport and install compared to other materials, and they can withstand high pressure and extreme temperatures. However, it is important to ensure that the aluminum sheets used for water tanks are of high quality and meet the necessary standards to ensure the safety and longevity of the tank.

- Q:Can aluminum sheets be used for furniture manufacturing?

- Certainly! Furniture manufacturing can make use of aluminum sheets. Aluminum is a highly versatile material that possesses several advantageous properties, making it suitable for the production of furniture. Lightweight, durable, and corrosion-resistant, aluminum can be easily shaped into various sizes and forms. Additionally, aluminum has a sleek and modern appearance, making it a popular choice for contemporary furniture designs. Frames, legs, and other structural components for chairs, tables, shelves, and cabinets can be fashioned from aluminum sheets. The versatility and durability of aluminum make it a viable option for furniture manufacturing, particularly for outdoor or industrial furniture that requires resistance to harsh weather conditions or heavy use.

- Q:Are aluminum sheets suitable for roofing systems?

- Indeed, aluminum sheets prove to be an appropriate option for roofing systems. The durability, lightweight composition, and corrosion resistance of aluminum render it a favored choice for rooftops. Moreover, aluminum possesses fire-resistant properties and can endure harsh weather conditions, including strong gusts and heavy precipitation. With their long lifespan and minimal upkeep requirements, aluminum roofing sheets present a financially sound choice over time. Furthermore, the highly reflective nature of aluminum aids in reducing energy expenses by maintaining cooler indoor temperatures in hot climates. In summary, aluminum sheets emerge as a dependable and effective preference for roofing systems.

- Q:What is the bending radius for aluminum sheets?

- The bending radius of aluminum sheets may vary depending on the sheet's thickness and alloy. In general, thinner sheets (around 1-3 mm) should have a bending radius of approximately 1.5 times their thickness. On the other hand, thicker sheets (over 3 mm) can increase the bending radius to around 2.5 times their thickness. Nevertheless, it's important to bear in mind that these are general guidelines and the bending radius may need to be adjusted according to the specific application and desired outcome. To obtain accurate bending radius information, it is always recommended to seek advice from a professional or consult the manufacturer's technical data sheets.

- Q:Can 101 aluminum sheets be used in the production of decorative panels?

- Yes, 101 aluminum sheets can be used in the production of decorative panels. 101 aluminum is a commercially pure aluminum alloy known for its excellent formability and corrosion resistance. These characteristics make it suitable for various applications, including decorative panels. The aluminum sheets can be easily shaped, cut, and fabricated to create intricate designs and patterns for decorative purposes. Additionally, the corrosion resistance of 101 aluminum ensures that the panels will maintain their appearance over time, even in outdoor or high-moisture environments.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Orange Pattern Embossed and PE Painted Aluminum Coils

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords