Flat Rolled Aluminum Coil Indiana - PE Coated Aluminum Coil for Decoration AA5052 H14

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

PE Coated aluminium coils are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive. Now we mainly exported to Asian countries, European countries, South America and North America.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

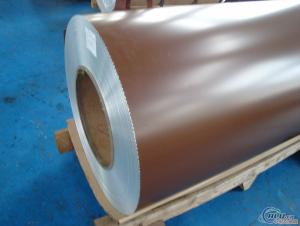

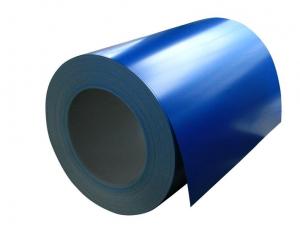

3.Image

4.Product Specification

| Alloy | Temper | Painting | Durable time | Coil Weight |

| AA5052 | H14 | PE Coated | 10-15 years | about 2.5 tons |

5. FAQ

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 8 tons.

- Q: How are aluminum coils joined together to form larger panels?

- Aluminum coils are joined together to form larger panels through a process called coil coating or coil joining. In this process, the edges of the coils are aligned and then welded, soldered, or bonded together using specialized techniques and adhesives. This ensures a strong and seamless connection between the coils, resulting in a larger aluminum panel.

- Q: How do aluminum coils contribute to lightweight vehicle design?

- Due to their unique properties and manufacturing processes, aluminum coils play a crucial role in the attainment of lightweight vehicle designs. Aluminum, being a lightweight material itself and weighing only about one-third of steel, is an ideal choice for lightweight vehicle design. When aluminum is formed into coils, it offers various advantages that contribute to the overall reduction in vehicle weight. First and foremost, aluminum coils possess high formability, enabling the creation of complex shapes using less material. This characteristic allows automakers to design intricate body panels and structural components that are both lightweight and possess improved aerodynamics and fuel efficiency. The ability to shape aluminum coils intricately also provides increased flexibility in design, leading to more innovative and visually appealing vehicle designs. Secondly, aluminum coils exhibit an exceptional strength-to-weight ratio, making them an excellent option for structural components. Despite their lightweight nature, aluminum coils provide exceptional structural integrity, ensuring the safety and durability of the vehicle. By incorporating aluminum coils into the chassis, suspension systems, and other critical components, automakers can reduce weight while maintaining the necessary strength and rigidity required for safe operation. Moreover, aluminum coils possess excellent corrosion resistance, which is vital for the long-term longevity of the vehicle. Corrosion can significantly impact the structural integrity and overall performance of a vehicle. By utilizing aluminum coils, automakers can minimize the risk of corrosion-related issues, resulting in a longer lifespan for the vehicle and reduced maintenance costs. Lastly, the utilization of aluminum coils aids in the overall reduction of vehicle weight, leading to improved fuel efficiency and decreased greenhouse gas emissions. Lighter vehicles require less energy for acceleration and to maintain speed, resulting in enhanced fuel economy. This benefit becomes increasingly significant as the automotive industry strives to develop more sustainable and eco-friendly vehicles. In conclusion, aluminum coils make a significant contribution to the design of lightweight vehicles by offering high formability, exceptional strength-to-weight ratio, corrosion resistance, and overall weight reduction. These properties enable automakers to design vehicles that are not only lighter but also safer, more fuel-efficient, and visually appealing. As the demand for lightweight vehicles continues to rise, aluminum coils play a vital role in achieving these design objectives.

- Q: How are aluminum coils tested for flatness?

- Aluminum coils are tested for flatness using various methods to ensure they meet the required standards. One common method is through the use of a straight edge, where a long, precision straight edge is placed on the surface of the coil. Technicians then visually inspect for any gaps or deviations between the straight edge and the coil's surface. If any gaps are found, it indicates that the coil is not flat and further analysis is required. Another method used is the straight edge ruler technique, where a ruler with a thin, flexible edge is placed on the coil's surface. By applying gentle pressure, technicians can identify any areas where the ruler does not make full contact with the coil, signaling irregularities in the flatness. Advanced techniques such as laser or optical methods are also employed to assess the flatness of aluminum coils. These methods use laser beams or optical sensors to measure the surface profile of the coil. The data collected is then analyzed to determine if any deviations from the desired flatness exist. These techniques provide accurate and precise results, allowing for a more detailed evaluation of the coil's flatness. Overall, the testing of aluminum coils for flatness is crucial to ensure that the coils meet the required standards for various applications. By employing a combination of visual inspection, straight edge techniques, and advanced laser or optical methods, manufacturers can ensure that the coils are flat and free from any irregularities that could affect their performance.

- Q: How are aluminum coils formed into different shapes and profiles?

- Aluminum coils are formed into different shapes and profiles through a process known as aluminum coil slitting and forming. This involves passing the coil through a series of rollers and dies that apply pressure and force to shape the metal into the desired form. The specific shape and profile are determined by the design of the rollers and dies used in the process.

- Q: I would like to know because I'm getting a sword with an aluminum sheathe.

- Cinderblock is correct. Alloys can be made of almost anything. Aluminum is made in like 2700 different grades/alloy combinations - some pure, most less so. Aluminum is the 3rd most plentiful element in the earths crust.

- Q: Can aluminum coils be used in the manufacturing of lighting fixtures?

- Yes, aluminum coils can be used in the manufacturing of lighting fixtures. Aluminum is a versatile and lightweight material that has excellent thermal conductivity properties, making it suitable for dissipating heat generated by the light source. Additionally, aluminum coils are easily moldable, allowing for the creation of intricate designs and shapes in lighting fixtures. The corrosion-resistant nature of aluminum also ensures the longevity and durability of the lighting fixture. Overall, aluminum coils are a popular choice in the manufacturing of lighting fixtures due to their numerous advantages.

- Q: Can aluminum coils be used for window frames?

- Certainly, window frames can indeed be made using aluminum coils. Aluminum is widely favored for window frames owing to its enduring nature, lightweight composition, and ability to resist corrosion. It is extensively employed in both residential and commercial settings. Aluminum coils can be effortlessly molded and adjusted to accommodate diverse window dimensions and designs. Additionally, aluminum frames provide exceptional thermal insulation qualities, thereby enhancing energy efficiency in structures. All in all, aluminum coils represent a dependable and pragmatic choice for constructing window frames.

- Q: Can aluminum coils be used in HVAC systems?

- Yes, aluminum coils can be used in HVAC systems. In fact, aluminum coils are commonly used as an alternative to traditional copper coils in many HVAC applications. Aluminum coils offer several benefits such as improved energy efficiency, corrosion resistance, and lighter weight, making them a popular choice for HVAC systems.

- Q: Is there aluminum coil of 44mm wide and 0.40mm thick?

- The common width of aluminum coil is 1000mm or 1220mm. If you want 0.4mm*1000MM aluminum coil, you can strip 0.4mm*1000MM aluminum coil.

- Q: Is it possible to use a saw to cut aluminum coils?

- <p>Yes, aluminum coils can be cut with a saw, but it's important to use the right type of saw. A hacksaw or a fine-toothed metal cutting saw is suitable for cutting aluminum. Lubrication is also crucial to reduce friction and prevent the saw blade from overheating. When cutting aluminum, it's advisable to use a cutting fluid or a light machine oil to keep the blade cool and ensure a clean, smooth cut. Always follow safety precautions and wear appropriate protective gear when cutting metal.</p>

Send your message to us

Flat Rolled Aluminum Coil Indiana - PE Coated Aluminum Coil for Decoration AA5052 H14

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords