G8 Aluminum Coil - PE Color Coated Aluminium Coils for Decoration AA3003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

PE Coated aluminium coils are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. However, the price of PE Colored aluminium coils is much more competitive than PVDF aluminium coils. So many customers prefer PE coated aluminium coils.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

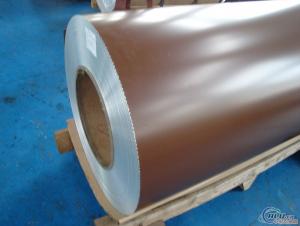

3.Image

4. Products Specification

| Alloy | Painting | Color Series | Coating Thickness | Coil Weight |

| AA3003 | PE | RAL | 22-25 MICRONS | About 2.5 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 8 tons.

- Q: 1mm how much is one square meter for aluminum rolls?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet.

- Q: Can aluminum coils be used in the production of household appliances?

- Household appliances can indeed utilize aluminum coils in their production. Aluminum, a material known for its lightweight and durable nature, boasts exceptional thermal conductivity, rendering it highly suitable for various appliance applications. Refrigerators, air conditioners, and heat pumps, for instance, greatly benefit from the utilization of aluminum coils. These coils are commonly employed in the condenser and evaporator coils of such appliances, efficiently facilitating heat transfer. Moreover, the corrosion resistance of aluminum coils is pivotal in ensuring the longevity and optimal performance of household appliances. Consequently, owing to their advantageous properties and benefits, aluminum coils remain a favored option in the production of household appliances.

- Q: Can aluminum coils be used in the production of aluminum curtain walls?

- Yes, aluminum coils can be used in the production of aluminum curtain walls. Aluminum coils are typically used as the raw material in the manufacturing process of aluminum curtain walls. These coils undergo various processes, such as rolling, cutting, and shaping, to create the desired components of the curtain wall system. The lightweight and corrosion-resistant properties of aluminum make it an ideal material for curtain walls, as it provides structural stability, durability, and aesthetic appeal to the building façade. Overall, aluminum coils play a crucial role in the production of aluminum curtain walls, ensuring the quality and performance of the final product.

- Q: Can the displacement sensor be used for real-time measurement of the aluminum coil thickness?

- Yes, you can use two sensors to measure thickness, either contact sensor or laser sensor

- Q: Can aluminum coils withstand high temperatures?

- Yes, aluminum coils can withstand high temperatures. Aluminum has a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit), making it suitable for applications where high temperatures are involved.

- Q: Are there any limitations to the maximum coil length of aluminum coils?

- Yes, there are limitations to the maximum coil length of aluminum coils. The maximum coil length depends on various factors such as the thickness and width of the aluminum coil, the strength and tensile properties of the aluminum alloy, the equipment used for coil processing, and the intended application of the coil. One limitation is the strength and ductility of the aluminum alloy being used. Aluminum alloys with higher strength and lower ductility may have limitations on the maximum coil length due to the risk of coil breakage or deformation during processing or handling. Another limitation is the equipment used for coil processing. The maximum coil length is often determined by the size and capabilities of the equipment used for slitting, cutting, or forming the coils. If the equipment has a limited capacity or is not designed for longer coils, it may not be able to handle or process longer lengths effectively. The intended application of the coil can also impose limitations on the maximum coil length. For example, if the coil is intended for transportation purposes, such as in the automotive industry, there may be restrictions on the maximum coil length based on the size and weight limitations of the vehicles. Additionally, logistical factors such as transportation and storage can also impose limitations on the maximum coil length. Longer coils may be more difficult to handle, transport, and store, which can increase the risk of damage or pose challenges in terms of logistics and space requirements. Therefore, while there is no specific universal limit to the maximum coil length of aluminum coils, it is essential to consider various factors such as alloy properties, equipment capabilities, application requirements, and logistical considerations to determine the practical limitations of coil length for a specific situation.

- Q: What are the common maintenance practices for aluminum coils?

- To maintain aluminum coils in good condition, it is necessary to regularly clean them, inspect for any damage or corrosion, and ensure proper airflow around them. Cleaning is crucial to eliminate accumulated dirt, debris, and other contaminants. This can be achieved by gently brushing or vacuuming the coils, or by using a mild detergent and water solution for more stubborn dirt. It's important to avoid the use of harsh chemicals or abrasive materials that could harm the aluminum surface. Inspecting the coils for damage or corrosion is also essential for their performance and longevity. Any signs of physical damage, like dents or bends, should be promptly addressed to prevent further deterioration. Additionally, corrosion can occur due to exposure to moisture or chemicals, so it's important to check for rust or discoloration. If corrosion is present, it should be treated and the cause of it should be identified and resolved to prevent future damage. Proper airflow around the coils is crucial for efficient operation. Obstructions or blockages in the surrounding area should be cleared to ensure adequate air circulation. This may include removing debris or objects that restrict airflow and ensuring appropriate spacing between the coils and nearby objects. Regular inspection of air filters and the ventilation system is also important to prevent any restrictions that could hinder airflow. In conclusion, regular cleaning, inspection, and maintenance of aluminum coils are necessary to ensure optimal performance and prolong their lifespan. It is advisable to follow manufacturer guidelines and seek professional advice if any issues or concerns arise.

- Q: Can aluminum coils be used in electrical cables?

- Yes, aluminum coils can be used in electrical cables. Aluminum is a commonly used material for electrical conductors due to its excellent electrical conductivity and relatively low cost compared to copper. It is especially used in power transmission and distribution cables where long-distance transmission is required. Aluminum coils are often used in overhead power lines and underground cables. However, it is important to note that aluminum has a lower tensile strength than copper, so the cables need to be properly designed and manufactured to ensure adequate mechanical strength. Additionally, aluminum conductors require larger cross-sectional areas compared to copper to achieve the same electrical performance, which can result in slightly larger cable sizes.

- Q: Can aluminum coils be used for electrical connectors?

- Yes, aluminum coils can be used for electrical connectors. Aluminum is a commonly used material for electrical connectors due to its excellent electrical conductivity, relatively low cost, and lightweight properties. It is widely used in various electrical applications, including power transmission and distribution systems, electrical motors, and transformers. However, it is important to ensure proper insulation and protection of the aluminum coils to prevent corrosion and ensure long-term reliability of the electrical connections.

- Q: Are aluminum coils suitable for food and beverage packaging?

- Yes, aluminum coils are suitable for food and beverage packaging. Aluminum is a versatile material that offers various advantages for packaging applications. It is lightweight, making it easy to transport and handle. Aluminum is also highly resistant to corrosion, which ensures that the packaging remains intact and protects the contents from external factors. Additionally, aluminum has excellent thermal conductivity, allowing for efficient heat transfer, which is beneficial for food and beverage products that require temperature control. It is also impermeable to light, moisture, and oxygen, providing an excellent barrier to maintain the quality and freshness of the packaged items. Furthermore, aluminum is recyclable and can be reused, making it an environmentally friendly choice for packaging. Overall, aluminum coils are a reliable and suitable option for food and beverage packaging due to their durability, protective properties, and sustainability.

Send your message to us

G8 Aluminum Coil - PE Color Coated Aluminium Coils for Decoration AA3003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords