5083 Aluminum Coil Price - PE Coated Aluminum Coils for Decoration Blue AA3003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

PE Coated aluminium coils are widly used in decoration field.For example, it can used in ceiling, wall curtain ect. For the painting kinds, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much cheaper than PVDF.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

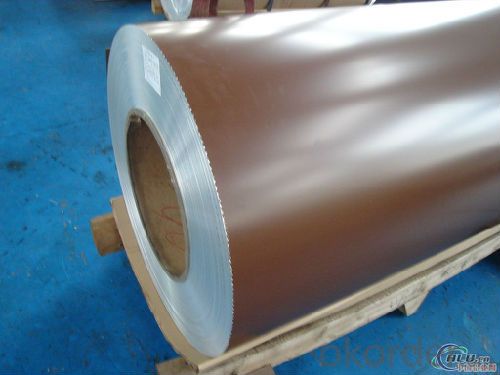

3. Image

4.Products Specifcation

| Alloy | Temper | Color | Coil ID | Coated Thickness |

| AA3003 | H14 | PE Blue | 505mm | 22-25 microns |

5. FAQ

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: how many chloride ions are present? how many chlorine ions are present? what is the mass in grams of one formula unit of aluminum chloride?

- Aluminum Chloride is simply AlCl3 So In each mole of AlCl3 there are 1 mol of Al 3 mol of Cl We know (from periodic table), 1 mol of Al weighs 26.98 g 1 mol of Cl weighs 35.47g so 1 mol of AlCl3 weighs 26.98g + 3x35.47g = 133.39 g sooo moles of AlCl3 = 37.2 g /133.39 g/mol = 0.279 mol in one mol of anything, there are 6.02 x 10 ^ 23 of that thing... so we have 0.279 mol x 6.02 x 10 ^ 23 molecules /mole = 1.68 x 10 ^ 23 And, we know one molecule of AlCl3 dissociates into one Al ion and 3 Cl ions sooo 1.68 x 10 ^ 23 AlCl3 ions dissociate into 1.68 x 10 ^ 23 Al ions so answer is 1.68 x 10 ^ 23 Al ions

- Q: My budgies took at bath in an aluminum pie tin today. At first they bit it just because it was their first time. Should I be worried that they might get poisoned?

- Nah, when I was a baby I took baths in aluminum pie tins all the time.

- Q: This question asks for methods to assess the quality of aluminum coils.

- <p>To determine the quality of aluminum coils, consider several factors: purity and alloy composition, which affects strength and corrosion resistance; surface condition, checking for scratches, dents, or impurities that can affect performance; mechanical properties like tensile strength and elongation; and dimensional accuracy, including thickness, width, and straightness. Conduct tests such as hardness tests, tensile tests, and corrosion resistance tests. Visual inspection and using measuring tools for dimensional checks are also crucial. Compliance with industry standards and certifications from recognized bodies can also indicate quality.</p>

- Q: What are the different coil pattern options for aluminum coils?

- There are several different coil pattern options available for aluminum coils, depending on the specific application and desired aesthetic. Some common coil pattern options include: 1. Stucco Pattern: This pattern features a textured, raised surface that resembles the appearance of stucco. It provides increased durability and a non-slip surface, making it suitable for applications such as flooring or outdoor surfaces. 2. Diamond Pattern: This pattern consists of small diamond-shaped embossed designs, providing a visually appealing and slip-resistant surface. It is commonly used in applications such as stair treads, walkways, and decorative panels. 3. Wood Grain Pattern: This pattern replicates the appearance of natural wood grain, making it an attractive option for various architectural and interior design purposes. It is often used in applications such as wall cladding, ceiling panels, and furniture. 4. Checkered Pattern: Also known as the checker plate pattern, it features a grid of raised diamonds or squares. This pattern offers excellent slip resistance and is commonly used in applications where safety is a priority, such as ramps, industrial flooring, and staircases. 5. Plain Smooth Pattern: This pattern has a smooth, flat surface without any embossed designs or patterns. It is a versatile option suitable for a wide range of applications, including roofing, gutters, and general fabrication. 6. Ribbed Pattern: This pattern consists of parallel lines or ribs running along the length of the coil. It provides added strength and rigidity, making it commonly used in applications such as truck bodies, trailers, and industrial equipment. These are just a few examples of the various coil pattern options available for aluminum coils. The choice of pattern ultimately depends on the specific requirements of the project, such as functionality, durability, and aesthetic preferences.

- Q: What is the typical thickness tolerance for aluminum coils?

- The typical thickness tolerance for aluminum coils can vary depending on the specific requirements and specifications of the customer or industry. However, a common range for thickness tolerance in aluminum coils is typically around +/- 0.002 inches.

- Q: Can aluminum coils be used in the production of aluminum windows?

- Yes, aluminum coils can be used in the production of aluminum windows. Aluminum coils are often used as a raw material in the manufacturing process of aluminum windows. These coils are typically made from high-quality aluminum and are rolled into thin, flat sheets. These sheets can then be cut and shaped into the desired frame size and design for the windows. Aluminum is a popular material for window frames due to its durability, lightweight nature, and resistance to corrosion. The use of aluminum coils in the production of aluminum windows allows for efficient and cost-effective manufacturing processes while also providing a high-quality end product.

- Q: Can aluminum coils be formed into different shapes?

- Yes, aluminum coils can be formed into different shapes. Aluminum is a highly malleable metal, which means it can easily be bent, shaped, and formed without breaking. This property makes it an ideal material for various applications where flexibility and versatility are required. Aluminum coils can be formed into different shapes using a variety of techniques, such as bending, rolling, stamping, extrusion, or even by using specialized machinery like a coil forming machine. These processes allow the aluminum coils to be transformed into a wide range of shapes, including sheets, plates, tubes, wires, or complex three-dimensional forms. The ability to form aluminum coils into different shapes makes it an excellent choice for industries such as construction, automotive, aerospace, and manufacturing, where customized parts and components are often needed.

- Q: A certain ionic compound is made entirely of aluminum and oxygenWhat is the formula for this compound?

- Aluminium Oxide: Al2O3 The ions: Al3+ .............. O2- When they bond: It is ionic as it takes place by the transfer of electrons from Aluminium(metal) to Oxygen(Non-metal). Hence, the bond is: Al2O3, Aluminium Oxide or alumina.

- Q: Can aluminum coils be painted or coated?

- Absolutely! It is entirely possible to paint or apply a coating to aluminum coils. Aluminum, being a remarkably adaptable material, can be adorned with a diverse range of finishes to elevate its aesthetic appeal and safeguard it against corrosion. The typical procedure for painting or coating aluminum coils entails cleansing and prepping the surface, administering a primer, and subsequently applying the desired paint or coating. The selection of paint or coating relies on the desired outcome and the specific purpose of the aluminum coil.

- Q: Are aluminum coils suitable for insulation purposes?

- Indeed, aluminum coils are well-suited for insulation purposes due to their exceptional heat and electricity conductivity. This quality makes them a perfect selection for insulation applications. Aluminum coils find utility in a wide range of uses such as HVAC systems, refrigeration units, and electrical wiring. Typically, these coils are coated with an insulating material like polyurethane foam or fiberglass to augment their insulation capabilities. The amalgamation of aluminum and insulation works wonders in impeding the transfer of heat or cold, thereby providing superb thermal insulation. Moreover, aluminum is lightweight, sturdy, and resistant to corrosion, rendering it a dependable choice for long-lasting insulation requirements.

Send your message to us

5083 Aluminum Coil Price - PE Coated Aluminum Coils for Decoration Blue AA3003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords