Flat Rolled Aluminum Coil Indiana - PVDF Coating Aluminum for Building Decorations

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of PVDF Coating Aluminum for Building Decorations Description:

Aluminium coated sheetl/ aluminium colour shee is PE (polyester) coating: high molecular polymer as monomer and addition of alkyd, is a UV-resistant coating. It can be classified either as matt or glossy according to your needs. The compact molecule structure makes the point surface luster and smooth, which assures good printing on the panels’ surface.

Aluminium Coated Sheet is widely and mainly used for building decoration, such as ACP, aluminum, ceilings, aluminum sheets, honeycomb panels and aluminum roofing, lighting decoration, household electrical appliances, food package (such as pop can cover & ring-pull), furniture ect.

2.Main Features of PVDF Coating Aluminum for Building Decorations:

Good Corrosion Resistance

Good Machinability

High Quality

Competitive Price

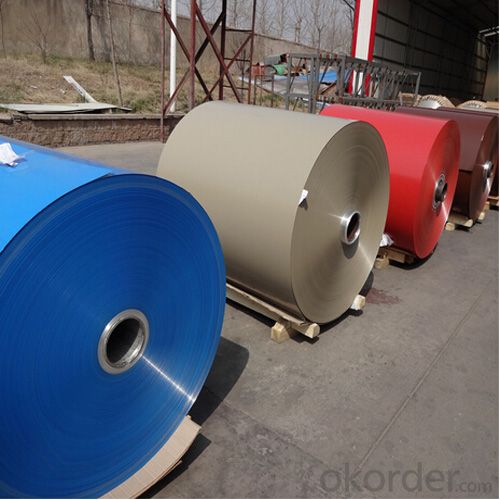

3. PVDF Coating Aluminum for Building Decorations Images:

4. PVDF Coating Aluminum for Building Decorations Specification:

Grade | 1050,1060,1070, 1100, 1200, 2024,3003, 3004,3005, 3105, 5005,5052 5182,5754,8011 etc. |

Thickness | 0.1~1.5mm |

Width | 100~2200mm |

Application | Decorative Materials |

Surface Treatment | Coated |

Temper | O - H112 |

Hardness | More than 2H |

Yield (≥ MPa) | 160 |

Temper | O - H112 |

Ultimate Strength (≥ MPa) | 175 |

Elongation (≥ %) | 6 |

Packing material | Moisture-proof agent, steel tape bundle, wooden pallet, brown paper |

Method | Vertical( eye to sky) or horizontal( eye to wall) |

Standard spec | 1000mm xC, 1200mm xC etc |

Shipping | Container Loading or Bulk Pack |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: How do aluminum coils contribute to noise isolation?

- Aluminum coils can contribute to noise isolation in several ways. Firstly, the use of aluminum as a material for coils provides excellent thermal and electrical conductivity, which helps to dissipate heat and electromagnetic interference. This reduces the chances of noise generated by these factors. Additionally, aluminum coils can be designed with specific properties that enhance noise isolation. By using thicker aluminum wire, the coil can have a higher resistance, reducing the transmission of electrical noise. Furthermore, the shape and size of the coil can be optimized to minimize vibrations and resonance, which are common sources of noise. Furthermore, aluminum coils can be used in conjunction with other noise isolating materials. For example, they can be combined with acoustic foam or other sound-absorbing materials, creating a barrier that prevents sound transmission. The aluminum coil acts as a structural support while the additional materials absorb and dampen sound waves, further enhancing noise isolation. Overall, aluminum coils contribute to noise isolation by dissipating heat and electromagnetic interference, minimizing vibrations and resonance, and providing a structural support for other noise isolating materials.

- Q: Can aluminum coils be painted or coated after installation?

- Yes, aluminum coils can be painted or coated after installation.

- Q: What specific tools are required for handling and working with aluminum coils?

- <p>Working with aluminum coils typically requires specialized tools to ensure safety and efficiency. These include cutting tools like metal snips or shears designed for aluminum, which are crucial for cutting the coils without damaging them. Additionally, a coil carrier or uncoiler is necessary for handling and unrolling the coils without causing injury or deformation. Protective gear such as gloves and safety glasses is also essential to prevent injuries from sharp edges or debris. For more precise work, a metal straightener or leveling machine may be needed to correct any warping in the aluminum coils.</p>

- Q: Is it okay to combine copper with aluminum in case of minting or coin making? Thanks :)

- i think its fine

- Q: What are the strength properties of aluminum coils?

- The strength properties of aluminum coils include high tensile strength, excellent formability, and good resistance to corrosion. Aluminum coils have a high strength-to-weight ratio, making them a preferred choice in various industries such as automotive, aerospace, and construction. They exhibit good resistance to fatigue and are capable of withstanding heavy loads without deformation or breakage. Additionally, aluminum coils offer excellent formability, allowing for easy shaping and bending without compromising their structural integrity. Moreover, aluminum's natural oxide layer provides a protective barrier against corrosion, making aluminum coils highly resistant to rust and other forms of degradation. Overall, the strength properties of aluminum coils make them a versatile and reliable material for a wide range of applications.

- Q: Is it safe to use aluminum coils in various applications?

- <p>Yes, aluminum coils are generally safe to use. They are widely used in various industries due to their excellent thermal conductivity, corrosion resistance, and lightweight properties. Aluminum coils are non-toxic and do not emit harmful substances, making them safe for applications such as food packaging and construction. However, safety can depend on specific uses and manufacturing processes, so it's important to ensure that the coils meet the required safety standards for their intended application.</p>

- Q: How do aluminum coils perform in extreme weather conditions?

- Aluminum coils are renowned for their outstanding performance in challenging weather conditions. With their inherent properties, aluminum coils exhibit remarkable resistance to corrosion, rendering them ideal for usage in areas with high humidity, coastal regions, and locations susceptible to acid rain or industrial pollution. Furthermore, aluminum coils possess a high melting point, enabling them to endure extreme heat without warping or distorting. In frigid weather, aluminum coils demonstrate exceptional durability and do not become brittle like some alternative materials. They maintain their structural integrity, ensuring optimal performance even in freezing temperatures. Additionally, aluminum coils possess excellent thermal conductivity, enhancing their efficiency in heat transfer and defrosting capabilities, crucial for HVAC systems operating in cold weather conditions. In hot and humid climates, aluminum coils excel in resisting corrosion, preventing moisture accumulation, and sustaining their efficiency. Crafted to withstand high humidity levels, they prevent the growth of mold or bacteria that could compromise indoor air quality. Moreover, the lightweight nature of aluminum coils aids in dissipating heat rapidly, improving overall cooling performance and energy efficiency. Furthermore, aluminum coils exhibit remarkable durability and can endure extreme weather events, including hurricanes, strong winds, and hailstorms. Engineered to be robust and impact-resistant, they withstand harsh weather conditions without sustaining damage. Overall, aluminum coils have proven their reliability and effectiveness in extreme weather conditions, delivering long-lasting performance and durability. Their corrosion resistance, ability to withstand high and low temperatures, and capacity to endure severe weather events make them an excellent choice for diverse applications, such as HVAC systems, refrigeration units, and outdoor equipment.

- Q: Im doing an assignment for science and i need to know the nuclear charge of Aluminium?and also is there a difference between Aluminium and Aluminum or can it just be spelt differently?

- Aluminium is the European spelling Aluminum is the American spelling...just like colour and color. Aluminium ion usually has a 3+ charge

- Q: I need to make aluminum powder that is fine! I don't have a mill to use or something like that. If I fill literally the whole coffee blender, will that get it fine? I want to make an ok amount of it. I tried to use sand paper which makes it as fine as I want it but takes a while of sanding.

- How To Make Aluminum Powder

- Q: i know that your not suppose to use DC for aluminum only with AC but is it possible?

- be careful scrambling aluminum molecules...it gets brittle in a hurry...do it wrong and you're gonna mess up a lot of stuff.

Send your message to us

Flat Rolled Aluminum Coil Indiana - PVDF Coating Aluminum for Building Decorations

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords