Outdoor Plastic Floor Wpc Decking Board ASA Surface Co-extrusion

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1> What is WPC?

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

2> What’s WPC used for?

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

FAQ

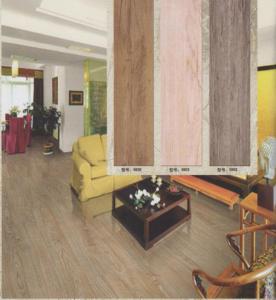

3> Why choose WPC decking?

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

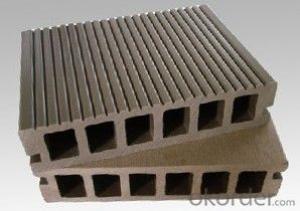

4> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

5> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

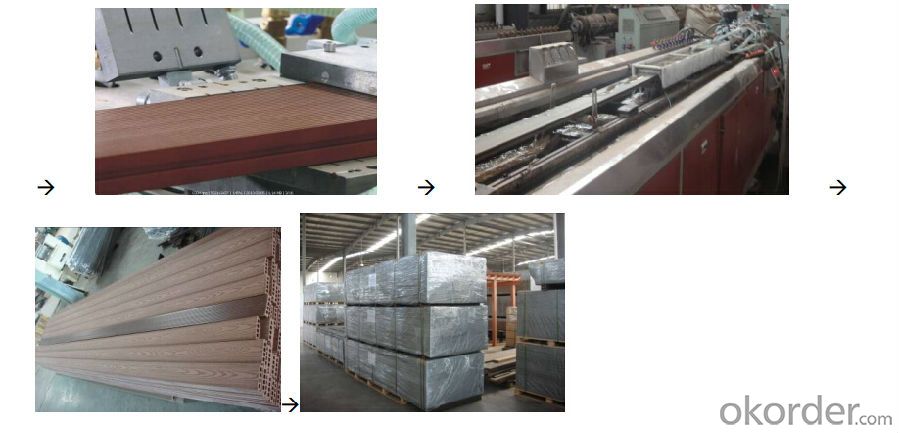

6> How’s WPC made?

7> Specification of WPC?

A. Weatherability

suitable from -40° C to +60° C, UV resistance

B. Test Data

| Testing Item | Technical Requirements | Value of Test |

| Water Content % | ≤2 | 0.4 |

Rockwell Hardness (HRR) | ≥60 | 80 |

Thickness Swelling after Water Absorption (%) | ≤1 | 0.2 |

Screw Holding | Surface of board ≥1300 | 3870 |

| End of board ≥1200 | 3460 | |

Static Bending | ≥20 | 28 |

Bending Elastic | ≥1800 | 4610 |

Abrasion | ≤0.08 | 0.06 |

Hammer falling impact in low temperature, broken (pcs) | ≤1 | 1 |

State after Heating | No babbles, cracks and pockmarks | - |

Rate of Size Change with Heating (%) | ±2.5 | -0.38~-0.45 |

Report Number: 201107126

Type of sample: 90x25x820mm, Solid

C. Surface treatment

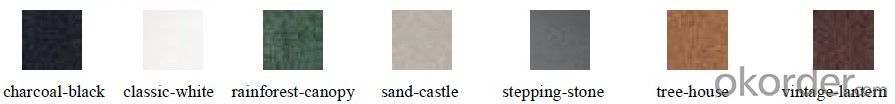

D. Main colors available:

charcoal-black; classic-white; rinforest-canopy;sand-castle; stepping-stone; tree-house; vintage-lantern .

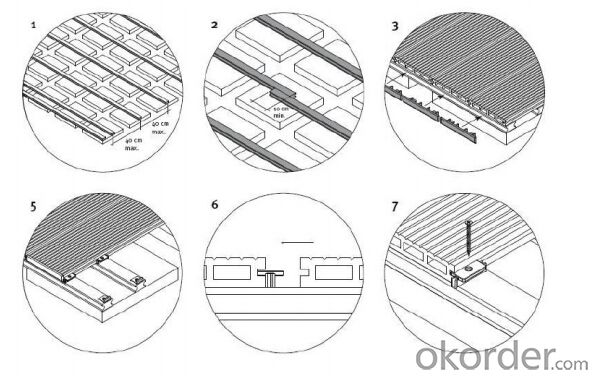

E. How to install

Company Information

8> About CNBM and It’s WPC products

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

Our unique advantages:

* Preferential payment terms

* Good and reasonable price

* Quality guarantee -- CNBM won't let a single small deal ruin our reputation and brand, so quality is

our lifetime.

* Professional team for CRM order processing & QA & logistics

*Global logistic database, originated from Dubai

- Q: Because of the conditional twitching, there was a layer of not too thick carpet on the concrete floor, a layer of mats on the carpet and a bed sheet, and I did not know that it was good for the body, I am living on the 26th floor of the elevator apartment more

- not good. Sleep on the ground, not ventilated, because the body has moisture, long mat will be damp and easy to breed bacteria, have an impact on health.

- Q: I will be using prepaded laminate flooring on top of a concrete slab. Do I need to use an adhesive ? How does the floor stay down ?

- No do not use adhesive.Your laminate is a floating floor and will expand and contract with heating and cooling of the floor.You will need a moisture barrier(plastic sheeting)because all the prepadded laminate ive ever seen requires a moisture barrier over concrete slab.The weight of the floor keeps it down but if you attach it to anything it will cause the floor to buckle or seperate when it expands or contracts.Depending on where your installing it and what brand you may need to fill expansion gap with silicone and/or to glue the pieces together to keep moisture from getting down between the boards.

- Q: I have an acid washed concrete floor in my business. I am having a problem with the floor being hazy/dirty after washing. The floor is waxed. When i clean the floor I use 2 buckets of water ... One with neutral floor cleaner and one clean water rinse bucket. After the floor dries it has a haze over it ... if i rub my fingers on the floor the haze goes away but my fingertips become black from the residue ... what can i do to get my floor back to clean ... i get so many compliments on the dirty floor and i cant imagine what they will say once it is really clean ... Any Help Would Be Appreciated ....Thank You

- one possibillity is you're using to much neutral floor cleaner, and not rinsing well enough. if as you say the floor is waxed thats about the only likely cause.

- Q: Define functions H and K from R to R by the following formulas:For all x in R,H(x) = [floor](1) + 1 and K(x) = [ceiling](x)Does H = K? Explain.I hate to ask for homework help, but I just do not get this. At all. Help?

- think floor(x+a million/2) = floor(x). Then noting floor(x) is an integer and using the definition of floor(x+a million/2), we've floor(x) <= x+a million/2 < floor(x) + a million. Now, considering that we continuously have floor(x) <= x < x+a million/2, the above inequality is such as x - floor(x) < a million/2. finally, this inequality has as answer the union of [m, m+a million/2) the place m is any integer. all the stairs I made are trivially reversible (the two by using definition or I gave a proof), so as that union is likewise the answer set for floor(x+a million/2) = floor(x). --- you are able to very in fact mimic the above evidence to get one for the ceiling, yet i will make it easier to gain this.

- Q: I am installing vinyal floor tiles in the kitchen. I have self stick type tiles. My question is can I use tile adhesive with this type of tile and will it provide better adhesion.

- Hey, do what you can now. You'll have a nice clean floor for the years that you wait to afford the hardwood. Two years is a long wait and I guess some people are loaded... I'm sure you'd love to just do the hardwood now. You'll be able to install over it but if you have someone else doing it they'll prob. tell you you need to get up the vinyl first. It could be a prob w/ the meeting of the exsisting floor at the hallway as far as hieght matching up. Just go measure it. Good Luck.

- Q: How to maintain the composite wood flooring

- How to maintain the composite wood flooring

- Q: My name is Brittany and I work for my dads business Cleaner Image Marble. I can't help but notice there are so many questions on how to clean your marble floors? I can tell you that if you are lost and you think you have to replace your floor...DON'T!

- send them a note requesting more information.

- Q: I'm in an old building with wood floors. I think it' time to move beyond Swiffer Wet.

- If your wood floors look dingy, it could be a wax build up problem. You can use vinegar and water to polish them but be sure not to soak the floor like you might a vinyl floor, just damp mop. I recently bought the steam mop as seen on tv' and I am very very happy with it on tile and my wood floors!Just uses water!! Its so easy!! I would NOT scrub them with a brush or you can rub the polish off and leave them raw and vulnerable to being ruined by wet shoes. I also heard that if you put wax paper on your swifer kind of mop that that will offer a quick shine! If they are really worn out wood floors, you can hire someone to buff and polish them and they will look brand new!

- Q: I have just purchased laminated flooring. It is called KR Inspiration Treehill Gunstock Oak. Does anyone have information about this type of flooring?

- laminate flooring consists of a wood composite core. then it has a computer generated graphic applied over the wood core. then a melamine resin wear surface is added. if its a click board only two companies hold the patent to make the board and all companies buy from thees two companies. the price difference comes from the quality of the picture, the number of different pictures a run will contain, and the ac rating on a scale of 1 to 4. to install it you must let it sit in the room for 72 hrs. then you must leave an expansion joint around the whole room usually a quarter inch. all edges must be covered with molding or trim. door jams must be undercut. and you must use an underlayment foam. if you need more help feel free to contact me.

- Q: Paste the floor of a single pile of porcelain porphyry Han Yan like how much money a square? I looked at the next are about 30 to 60 yuan. Too black it too. On that point to wipe the cement to the ground a paste, rubber hammer a knock on a square meter 30 to 60. a day not earn more than 1,000 to 2,000 yuan. There are experts to talk about why so much more expensive

- The first is the price of different regions is not the same and then the price of hand and novice is not the same as a tile specifications will also affect the general price of the general now most of the local understanding of almost 40 or so, the specific look at the situation

Send your message to us

Outdoor Plastic Floor Wpc Decking Board ASA Surface Co-extrusion

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords