crack-resistant outdoor co-extrusion wpc decking/plastic composite decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Features of the Co-extrusion WPC Decking:

1. Recyclable, Eco-friendly, saving forest resources

2. With the look of the natural wood, but less timber problems

3. Moisture/water resistant, less rotten, proven under salt water condition

4. Barefoot friendly, anti-slip, less cracking, less warping

5. Requires no painting, no glue, low maintenance effort

6. Weather resistant, suitable from minus - 40 to 60 centigrade degree

7. Termites and insects resistant, and moldy-proof

8. Easy to install and clean

Specification of Co-extrusion WPC Decking:

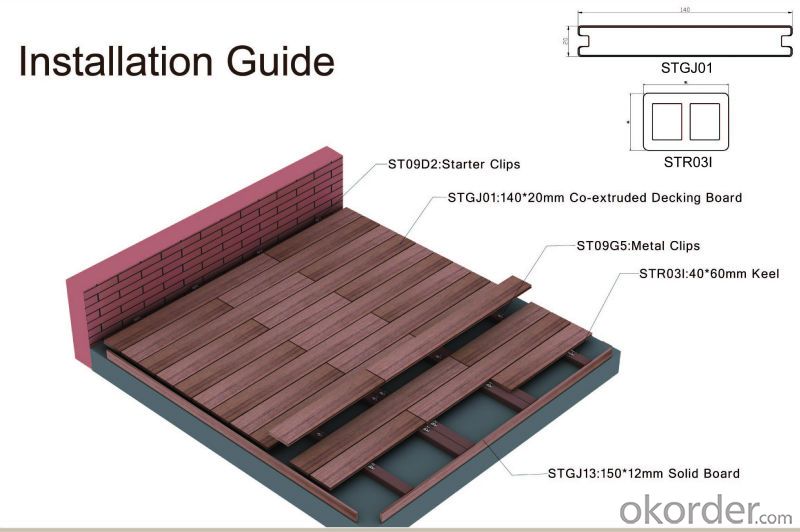

component | 30%HDPE(Grade A Recycled HDPE) 60%bamboo/wood fiber component 10%chemical addatives New material capped outside |

Size | 140X20mm |

Design | Solid decking |

Length | 2.9m/pc standard length, also from your required |

Surface treament | original, sanded, brushed |

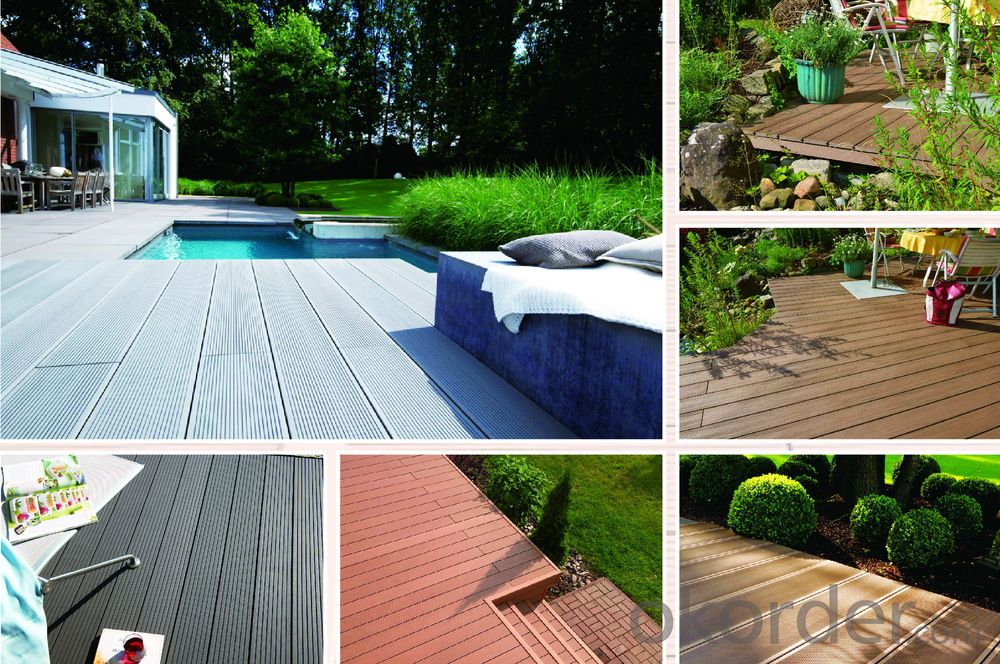

Color available | 5 regular colors for choice ( IPE,Walnut,graystone,Cedar,Rosewood) and we can adjust the new color according to the order requirement |

Cerfiticate | ISO9001, ISO14001, CE, FSC Certificate,"REACH"Test Reports by SGS; Intertek Test Report by ASTM standard..etc. |

Features: | 1.MORE STABLE “0” water absorption,”0’rotten,”0”mouldy.Less thermal expansion,less color fading. 2.MORE NATURAL Gradual change color,No scratches,No stain,No shinning,Deep wood grain with rough surface and vivid colors similar to real wood. 3.LONGER LIFETIME More than 25 years life time&Limited Warranty for 15 years. 4.Low Maintenance: Simple water is more than enough. |

Images of Co-extrusion WPC Decking:

FAQ of Co-extrusion WPC Decking :

1. Available Colours?

5 regular colors to choose ( IPE,Walnut,graystone,Cedar,Rosewood )

2. How to Install?

3.Packaging & Delivery?

Packaging Detail | 112pcs per pallet, 16pallets per 20ft, 24 pallets per 40ft. pallet size:290x105x1375px |

Delivery Detail | 3-4 weeks per 20ft |

- Q: Nature, icon, peace of mind floor, these three kinds of solid wood and composite purchase price each? Thank you more

- This question is really powerful, you say that the wood is expensive or barky trees expensive? Which a few brands which do not have hundreds of kinds of intoxicated abundance of feng 莶 both learn ax lulu floor are said that they can not tell the boss boss it! Nature is mainly solid wood, the elephant to strengthen the peace of mind should also be solid wood to the market to see chanting, and now the floor is not what the core competitiveness are similar, a little name of the floor are very good shop on the ground no one knows you use Is nature or natural.

- Q: i have moisture on the floor all along one of my walls, about 6 or 7 boards have to be replace.the floor is just glued to the concrete slab, i went to homedepot to buy something to apply to the concrete or something to apply before installing the new floor, but the clerk told me i have to replace the whole floor, because there is nothing to apply before the floor and underlayments are too thick and the floor would not be leveled.Please can anyone help me with a solution so i dont have to replace 1000sq ft of floor.thank you

- Short answer- Yes, you can. But, be aware of potential problems that can come later. You will have an organic material under the floor cut off from being able to breath- that basically means the surface you put over it will cut it off from being able to dry out if it get wet. If it gets wet, it will mildew - rot, and stink something awful. also, that old floor will have voids that you can not get to, making it a perfect habitat for insects. Although right now you are not able to actually, physically get under the old floor, if you or an expert applicator had to get to insect infestations, it is much more possible than if the old floor were covered. Covering it makes it less accessible and much more inviting to infestations. Basically, in construction, it is never a good idea to cover old material with new. A proper fix is to chip it out, level the floor correctly and lay down the new covering. I understand the prohibitive expense of this. But, imagine what you'll pay later with an improper job on top of what you will eventually have to do anyway?

- Q: 100 locusts know Hao version of Tongbao Kun ready to buy wood flooring, a friend said that the composite floor of the radiation formaldehyde or something. Answer, the composite wood floor with radiation and formaldehyde? How to identify and buy more environmentally friendly wood flooring more

- What decoration materials are radiation and formaldehyde, but with more problems with the fills, you can suddenly enriched, a few pots of Chlorophytum, live carbon, more than a period of time the wind can be a good floor to see the thickness, generally 1.23 About the knife can be used to see if there is no print, there is no need to select only the brand, things are just the same expensive advertising only.

- Q: I want to choose composite floor price of 30-40 yuan or so (quality to go to), which brand of suitable for some?

- The price, the quality of the hard to go.

- Q: How many pieces of composite flooring?

- Hello friends, who knows ah. How many pieces are there. It is not the same.

- Q: I am a real estate development enterprises to do the tender procurement work, would like to know about the standard decoration works, the use of floor tiles and laminate flooring contrast have advantages and disadvantages, please help focus on explain the strengthening of the composite floor on the construction process and the late intestinal valve Co-operation of the Office of the stall wiping the adverse effects of maintenance issues, with or without significant quality risks! Question added: I do not know which heroes have the shape of the report and the like, made up to the big intestine flap fit the bones of the bureaucratic school to learn, you give me the answer I have considered, and has formed a simple Of the report, but the feeling is not very full of content, did not impress the key points of leadership, or inconvenient to make decisions, or please a lot of help! The The Thank you first! More

- Qualified reinforced floor for bedroom and easy construction, floor tiles for living room laying.

- Q: Composite floor and solid wood floor difference in that?

- Solid wood: that is, wood, composite wood paste with adhesive on the suppression of the surface pattern is aluminum oxide wear layer. Solid wood prices are generally more than 100 yuan, hundreds of flooring is a high floor flooring solid wood shop need to play the dragon skeleton, so the thickness is greater than do not have to play keel, the common floor of the composite floor. Solid wood need to wax and anti-moth, compound do not. Solid wood with a long time can not help but knock there will be a lot of small pit, composite hardness, but also can knock off the skin. Solid wood with less glue, than the composite environmental protection. Volkswagen think solid wood than the composite show grade. Solid wood flooring foot feel good, texture, natural color, hardness is slightly worse, leaching paint the use of solid wood flooring is imported uv paint, no maintenance; but solid wood flooring because it is natural, texture, color 窢 chu The color is relatively high, the pavement need to play wood keel, the price is relatively high; strengthen the composite wood flooring to absorb the solid wood floor foot feel good, the advantages of natural color texture, and high-strength composite wood flooring easy to install, the price range Solid wood flooring and high-strength composite floor, but the hardness is the worst between the three. If your home is geothermal, you can only use composite, solid wood will be deformed

- Q: A square 80 yuan floor budget, with a composite wood floor or a large tiles good? Please introduce the brand

- Floor bar, composite floor 80 square can buy a mid-range of the floor tile is certainly more durable than the floor, but to take into account the floor is not so easy to assemble the floor, and the landlord budget and in this (floor fight like, the general price to buy It contains the installation fee). Tiles need to buy their own cement, yellow sand, but also to find workers paving workers wages, even if these cost only 30 per square, that tiles can only buy 50 yuan per square. Cost down the cost of each brick: If you buy 60 * 60 brick, about 18 yuan each piece. If you buy 80 * 80 brick, about 32 yuan each piece. The price of this brick is not how the kind of. Unless it goes to the kind of large building materials warehouse looking to see, or to the building materials market, hard to cut the fights of the fight to save the chew Chek Cheong Dan blind may be able to Amoy to the mid-range brick.

- Q: New house ready to renovate, bedroom inside want to use composite floor, but I heard that the composite floor radiation, is true or false ah? The The More

- No radiation at ease

Send your message to us

crack-resistant outdoor co-extrusion wpc decking/plastic composite decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords