Non-negative Pressure Building Water Supply Pump in Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Non-negative Pressure Building Water Supply Pump in Building

1.Structure of Non-negative Pressure Building Water Supply Pump in Building Description

High Pressure Booster Pumps is a high efficient water facility has characters of easy installation,saving space, water pool is not required.The pump energy efficient, using I mm converter speed control valve control over a large number of energy saving, the elimination of the high level of secondary pollution of water tanks,water tank eliminates the need to wash the cost and trouble,Water Pump achieve soft-start, start on the grid to reduce the impact of pumps to extend life.

2.Main Features of the Non-negative Pressure Building Water Supply Pump in Building

Water Supply: Urban water supply, boiler or condensate system, water filtering and distribution, water to water district, in charge of pressurized, high-rise building pressurization.

Industrial boosting: process water system, cleaning system, high pressure washing system, fire system.

Industrial liquid conveying: cooling and air conditioning systems, boiler feed and condensate systems, machine matching, acid and alkali.

Water Treatment: Industrial circulating system and processing system, environmental protection water treatment and infiltration analysis system, Ultrafiltration systems, reverse osmosis systems, distillation systems, separators, swimming pool

Irrigation: Agriculture irrigation and dewatering, sprinkler irrigation, drip irrigation.

3.Non-negative Pressure Building Water Supply Pump images

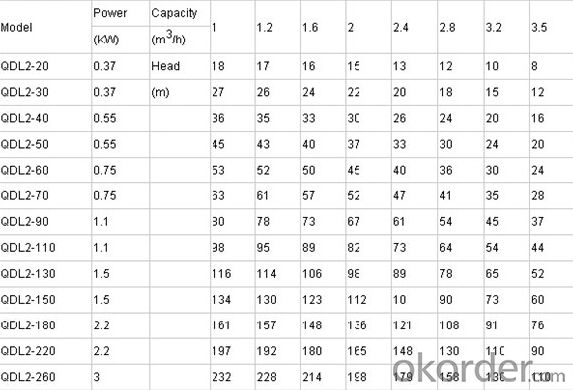

4.Non-negative Pressure Building Water Supply Pump Specification

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also

provide the pump model you are using now, price will be calculated as per the pump model, if not, we willrecommend relevant product for reference.

- Q: Rotary vacuum pump does not meet the requirements of vacuum, what are the reasons?

- 1) oil rotary vane vacuum pump is too low, no effect on the oil seal exhaust valve, rotary plug to refuel after large exhaust sound, and oil mist, that the level is too low, the gas can be eliminated.(2) the vacuum caused by the condensable steam pollution of oil should be changed, and new vacuum pump oil should be replaced.

- Q: How many millimeters is the diameter of the water outlet of the four inch pump?

- If it is a centrifugal pump, the nominal diameter of the outlet is less than 4 inches, there is a conical short tube to enlarge the standard 4 inch outlet flange, from here, is the standard 4 inch flange connection.

- Q: What are the functions of a disposable infusion pump?

- This is a very professional question, ha!I only know disposable infusion pumpsAttached: intelligent medical infusion pump and its application

- Q: What is double hydraulic pump?

- The 2 pumps are all coaxial connected together, driven by a motor, the general gear pump, piston pump

- Q: What is the "variable" of a variable pump? Is the displacement change or the flow change? Thank you

- Variable pump variable refers to the flow can be changed to distinguish from the constant flow of quantitative pumps.

- Q: What are the starting and stopping procedures for centrifugal pumps?

- Before using the centrifugal pump, the operation instructions of the centrifugal pump shall be read carefully and the specific operation procedures shall be understood so as to make proper use of the centrifugal pump products. The first step is the operation of centrifugal pump inlet valve of centrifugal pump centrifugal pump for all open cavity filled with liquid, close the outlet valve, start the motor, the motor speed is normal, can gradually open the outlet valve, to adjust to the desired condition. Pay attention to self suction centrifugal pump starts to open the exhaust valve, outlet valve should be opened quickly in the normal operation of the motor, to prevent air inlet pipe off caused by cavitation phenomenon produces centrifugal pump, centrifugal pump vibration phenomenon leads to noise of the smoke is not on the water.

- Q: Why should I pump the pump before starting the centrifugal pump?

- 1., if it is backward flow, it is not pumping;2., if the pump is installed underwater (such as submersible sewage pump), it is not pumping;3. pump is for installation in the form of suction. If no diversion irrigation pump, then the pump is full of air quality, air density is less than water, the pump will not be inside the gas out, the pump pressure will not be far less than the atmospheric pressure, the water will not be pressed into the pump to pump through irrigation formed inside the closed environment, the pump will start water out will cause local vacuum, entrance external water pressure into the pump is in inside and outside differential pressure, complete water movement. (vacuum water diversion is directly through the vacuum pump pumping the air in the pump, resulting in internal and external pressure difference, the external water pressure in the internal and external pressure is press into the inlet of the pump. The principle is the same as the pump. A standard atmosphere of =10m water column.)

- Q: What kind of motor does the hydraulic pump need?

- Calculation of actual oil pump power:First count the flow: Q=dn L / minD displacement / revN RPM / minThen calculate the actual power: N=QP/ (60K) kwQ flow L / minP MPa MPaK total efficiency (usually 0.85)I do not know what the landlord said, 2.5L is the displacement or flow at the end, the concept must not be confused

- Q: What's the meaning of the pump head in the water pump, please advise, thank you

- According to China Wikipedia network, the basic components of the water pump: motor, coupling, pump head (body) and chassis (horizontal).Pump is generally composed of pump body and pump head, in which the pump body refers to the spiral case, impeller, bearing, oil shell and sealing assembly, etc., the pump head refers to the impeller, bearings, oil ring and sealing rotating parts (including shaft), etc..

- Q: Why can't the centrifugal pump pump the vacuum?

- Running process: depending on the centrifugal pressure of the liquid in the impeller, the liquid is sucked into the liquid, and the liquid in the pump shell has the conversion of the energy form, so that the fluid can obtain the mechanical energy mainly with the static pressure.The characteristics of the system: the suction diameter than out of large diameter, the general valve installed.

Send your message to us

Non-negative Pressure Building Water Supply Pump in Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches