Mullite Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

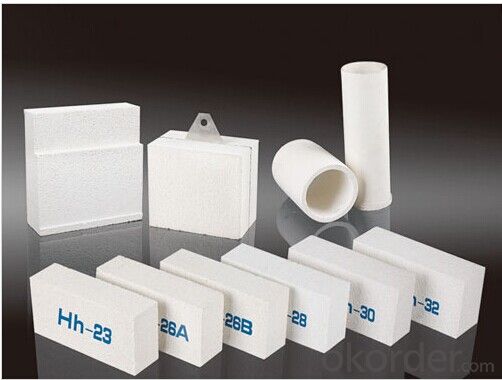

The raw material is crude highquality highalumin low ferrous content material. The unique polylight spheres producing technique is adopted. The main structure of this high-quality heat insulation refractory brick is mullite crystal phase. The characteristics of this product are:

High compression strength

Good high-temperature performance

Excellent thermal shock stability

Low thermal conductivity

Outstanding penetration resistance ability

Erosion resistance

Application:

It may be widely used as the lining and the heat insulation layer of industrial kilns in the fields of metallurgy, petrochemistry, machinery, power, ceramics, etc... It is an ideal product of long service life, energy-saving and effects-enhancing product.

| Brand

Item |

JM-23 |

JM-26 |

JM-28 |

JM-30 |

Al2O3(%)min | 37 | 50 | 60 | 68 |

Fe2O3(%)max | 1.0 | 1.0 | 0.7 | 0.5 |

SiO2(%)max | 45 | 43 | 36 | 29 |

Safty Application Temp.(°C)max | 1260 | 1430 | 1540 | 1650 |

Bulk Density(g/cm3) | 0.5 | 0.8 | 0.95 | 1.05 |

Bending strength(Mpa)min | 0.7 | 1.1 | 1.6 | 2.0 |

Crush strength(Mpa)min | 1.0 | 2.0 | 2.3 | 2.7 |

RLC(%)max | 1230°C×24h 0.3 | 1400°C×24h 0.4 | 1510°C×24h 0.5 | 1600°C×24h 0.6 |

Reversible thermal expansion at1090°C(%) max |

0.5 |

0.6 |

0.8 |

0.8 |

Thermal conductivity (w/m.k)max 400°C 600°C 800°C 1000°C |

0.15 0.17 0.19 0.24 |

0.28 0.31 0.33 0.35 |

0.33 0.36 0.39 0.42 |

0.41 0.43 0.45 0.48 |

- Q: Can insulating fire bricks be used in the construction of industrial chimneys?

- Yes, insulating fire bricks can be used in the construction of industrial chimneys. These bricks have excellent thermal insulation properties, which can help in reducing heat loss and improving the overall energy efficiency of the chimney. Additionally, insulating fire bricks are lightweight and resistant to high temperatures, making them suitable for the harsh conditions often found in industrial settings.

- Q: Can insulating fire bricks be used in the construction of refractory-lined vessels?

- Yes, insulating fire bricks can be used in the construction of refractory-lined vessels. Insulating fire bricks are specifically designed with low thermal conductivity, which makes them ideal for applications where insulation is required. In the construction of refractory-lined vessels, insulating fire bricks are often used in the outer layers of the lining to provide insulation and reduce heat loss. This helps to improve energy efficiency and maintain high temperatures inside the vessel. However, it is important to note that insulating fire bricks may not be suitable for all parts of the refractory lining, especially in areas where high mechanical strength or resistance to chemical attack is required. In such cases, other types of refractory bricks may need to be used.

- Q: Do insulating fire bricks require any special fireproofing treatments?

- There is no need for any special fireproofing treatments for insulating fire bricks. Insulating fire bricks are composed of lightweight materials that possess excellent insulation properties, such as refractory clay or ceramic fibers. These materials possess inherent fire resistance and can endure high temperatures without requiring extra fireproofing treatments. Nevertheless, it is crucial to guarantee the correct installation and utilization of insulating fire bricks in order to enhance their efficiency and lifespan.

- Q: Can insulating fire bricks be used in textile industry kilns?

- Insulating fire bricks are indeed applicable in the textile industry kilns. These bricks are specifically designed to endure extreme temperatures while providing exceptional insulation, rendering them appropriate for kiln usage. Within the textile industry, kilns are utilized for multiple procedures including fabric dyeing, drying, and curing. Implementing insulating fire bricks in these kilns guarantees the maintenance of a consistent and regulated temperature, resulting in efficient and uniform dispersion of heat. Furthermore, these fire bricks aid in minimizing heat loss, thereby leading to energy conservation and enhanced operational effectiveness. Hence, due to their thermal insulation properties and ability to endure high temperatures, insulating fire bricks are an ideal choice for textile industry kilns.

- Q: Can insulating fire bricks be used in solar power plants?

- Insulating fire bricks have the ability to be utilized in solar power plants. These bricks are specifically designed to possess exceptional thermal insulation properties, thus making them suitable for various applications that demand resistance to heat and energy efficiency. Solar power plants frequently experience high temperatures and the necessity to retain heat, particularly in concentrated solar power (CSP) systems. By using insulating fire bricks to line the walls and floors of CSP receivers and thermal storage systems, the loss of heat can be minimized and the conversion of solar energy into electricity can be maximized. Furthermore, insulating fire bricks can also find utility in other components of solar power plants, such as the insulation of solar panels or the construction of solar tower structures.

- Q: Are insulating fire bricks resistant to ultraviolet (UV) radiation?

- Insulating fire bricks usually lack resistance to ultraviolet (UV) radiation, which can lead to the deterioration and discoloration of materials, particularly those not specifically engineered to endure it. The main purpose of insulating fire bricks is their high temperature resistance and insulation properties, rather than their capacity to withstand UV radiation. Consequently, if exposed to long-term UV exposure, insulating fire bricks may undergo reduced performance, cracking, or deterioration. To ascertain the precise UV resistance of insulating fire bricks, it is crucial to refer to the manufacturer's specifications or guidelines, as certain manufacturers may provide specialized products with greater UV resistance.

- Q: Do insulating fire bricks require any maintenance?

- Yes, insulating fire bricks typically require minimal maintenance. They are designed to be durable and withstand high temperatures, so they generally do not need any special care or regular maintenance. However, it is important to inspect them periodically for any signs of damage or wear and tear, and if any issues are identified, they should be repaired or replaced to ensure their effective insulation properties.

- Q: Can insulating fire bricks be cut to size?

- Yes, insulating fire bricks can be cut to size. Insulating fire bricks are typically made from lightweight refractory materials, such as expanded clay or vermiculite, which makes them relatively easy to cut. They can be cut using common tools like saws or knives. It is important to note that when cutting insulating fire bricks, safety precautions should be taken, such as wearing protective goggles and a dust mask, as the cutting process may generate dust and small particles. Additionally, it is advisable to follow manufacturer's instructions or seek professional advice to ensure the proper technique and tools are used for cutting insulating fire bricks.

- Q: How do insulating fire bricks affect the overall cost of a project?

- The overall cost of a project can be greatly affected by insulating fire bricks, both in terms of immediate expenses and long-term savings. Despite their higher upfront cost compared to traditional bricks, insulating fire bricks offer superior insulation properties, resulting in substantial cost savings over time. Retaining heat and preventing heat transfer are among the primary advantages of insulating fire bricks. This leads to reduced energy consumption and lower utility bills, as less energy is needed to heat or cool a space. In industrial settings, insulating fire bricks can optimize the efficiency of furnaces, kilns, and other high-temperature equipment, resulting in increased productivity and lower operational costs. Furthermore, insulating fire bricks provide excellent thermal insulation, creating a stable and comfortable indoor environment. This is particularly beneficial in residential and commercial construction, as it reduces reliance on heating and cooling systems, further reducing energy consumption and associated costs. In addition to their insulation properties, insulating fire bricks are highly durable and resistant to high temperatures, chemical corrosion, and mechanical stress. This durability minimizes the need for frequent repairs or replacements, leading to long-term cost savings. Their lightweight nature also makes them easy to handle and install, potentially reducing labor costs during construction. Moreover, insulating fire bricks have a longer lifespan compared to traditional bricks, resulting in lower maintenance and replacement costs over time. Their ability to withstand extreme temperatures and harsh environmental conditions means they are less likely to deteriorate or require frequent repairs. In conclusion, despite their higher initial cost, insulating fire bricks offer superior insulation properties, energy efficiency, durability, and reduced maintenance needs, leading to significant cost savings throughout a project's lifespan. When evaluating the overall cost-effectiveness of using insulating fire bricks in a construction or industrial project, it is important to consider the long-term benefits and potential energy savings.

- Q: Can insulating fire bricks be cut or shaped to fit specific applications?

- Yes, insulating fire bricks can be cut or shaped to fit specific applications. They are often made of soft and porous materials, such as ceramic fiber or lightweight refractory materials, which can be easily cut using common tools like saws or knives. This flexibility allows for customization and fitting into various shapes and sizes to meet specific requirements in different applications.

Send your message to us

Mullite Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords