High Quality Ceramic Fiber Blanket with Low Thermal Conductivity Fireproof Insulation Rock Wool

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

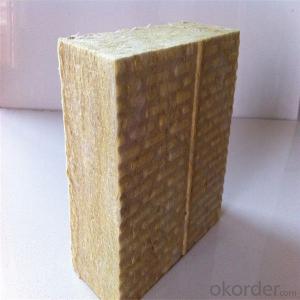

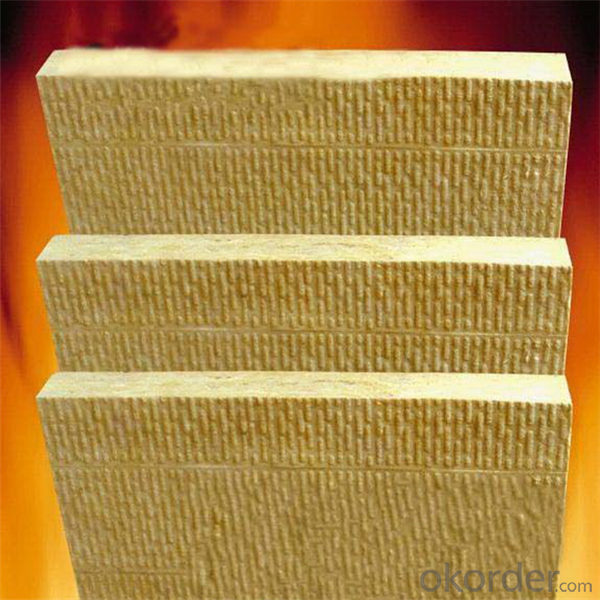

Fireproof Rock Wool Rock Wool Board with High Quality

Introduction

The external thermal insulation rockwool board is designed for the buildings of external thermal insulation system with thin finish coat and applys to external wall insulation and energy saving of new or existing building whose foundation wall is concrete or brick and other compact structures.

The external thermal insulation rockwool strip can also be used as fire barrier to improve the fire resistance of buildings external walls with other thermal insulation materials.

Features and Application

1,High compressive strength, tensile strength and good durability ensures the reliability and long-term stability of the product in the application.

2,Low thermal conductivity can effectively reduce the heat loss of the building to achieve energy saving and emission reduction.

3,External thermal insulation rockwool boards will not release heat and poisonous smoke because of its incombustibility and can effectively partition the spread of flam when fire occurs.

4,It has good performance of non-hygroscopicity, ageing resistance and long-term stability.

5,It is light weight and easy to be cut and processed

Specification

Standard Requirement | Deviation | |

Length | 1200mm | +10/-3mm |

Width | 600mm | +5/-3mm |

Thickness | 30mm—150mm | ±3mm |

Density | 40kg/m3—250kg/m3 | ±10kg/m3 |

Packaging & Shipping

Product is packed in polythene plastic thermal-shrink film.

Thickness of each package is within the range of 300-400 mm.

During transportation and storage, keep product away from moisture and compressive deformation

Genaraly 6-10pcs/pack

- Q: My dog currently is on a prescription high fiber food called DCO from Purinain the last year, the bag sizes have been reduced by 20% and the cost increased by more than 100%.(Now $30 for an 8 bag versus $14 for a 10 bag a year ago) What quot;over the counterquot; dog food has the highest fiber content that might be an adequate substitute for DCO?

- I don't see where it could be considered life threateningI mean our hair will grow back and its not like ur going to be putting peroxide on ur hair all the timeur hair will grow and it won't be forever damaged.,when ur putting on peroxide be careful from now on and just rinse with vinegar if you get some on ur hairno biggyanyways summer is coming and just think of it as free highlights.

- Q: After reading about how amazing and better for the hair ceramic irons are I have been on the search for an affordable one, well my search is over because I recently pruchased this set, however I have only heard people sing the praises of the chi ironSo have I invested in a second rate product or did I just happen to catch the deal of the century? I got the iron and 7 liquid tools for on $50.00 bucks! So if you know and before I open the box .tell me DEAL or No DEAL???!!!

- no deal obviously if it came with that many things its no deal i have hair straightenenr and its ceramic and it doesnt dry out my hair its perfect keep it it will be fine the only reason why people like chi so much is because it adds thine and bounce to your hair but also its really expensivedont worry we have all been thru it keep the straitener and dont waste your money on a hair straitener that costs as much as your houselol jk

- Q: My friend just got some subwoofers installed into his car, and as i was looking at his box, i realized he had put a towel inside his boxDo you recommend putting towels inside enclosures? and why do people do it?

- First, convert square feet of aluminum foil to square cm Next ,divide the 232.5 grams by the density to obtain the volume Next, divide the volume by the area in square centimeters to obtain the thickness of the aluminum foilFinally, convert the thickness in centimeters to millimeters.

- Q: I want to know the technical reason of different dye uptake of the same fibre and yarn whether it is cotton?

- Tension T1 20/sin44.5 28.53 poundsT2 240/sin24.5 578.74 pounds

- Q: I was thinking since fibre gets absorbed slower through your body then it might be good take as a supplement each day to prevent highs and lows of blood glucoseIs this right?

- Economic Space Heaters

- Q: I don't get enough fiber in my dietI try to eat more vegetables and whole grainsDue to a career change I am always on the go and I'm not always able to prepare a healthy meal for myselfI will sometimes grab a bag of chips or an unhealthy snack and goAre there alternatives available to help a person get more fiber in their diet?

- Hi there, yes fiber helps for weight lossBut I don't think for cholesterolThe best way to lower your cholesterol is by consuming lots of olive oil no OILHoney nuts cereol helps tooOlive Oil is good though it brings up your good cholesterol and lowers your bad cholesterol quickHope it works out for ya

- Q: 40-60 poundsI am 5'2, female at 165 poundsSixteen years of age, if that makes any differenceI would say I look ten pounds less than my actual weight, due to some muscle remaining from my exercise in the summerBiking three miles to school, an hour of Physical Education first period, two hours of tennis practice after school, three miles back home and an occasional late night or early morning run depending on how much my body can handleWith this as my VERY strenuous exercise regime (biking, running, tennis, P.E.) and only eating veggies/fruits with the obvious 8 glasses of water, is this a realistic goal? Someone be straight with me.

- There is no space heater that runs on 110 volt current going to heat more than two hundred well insulated square feet For safety purposes i would recommend that you by the small cube shaped ceramic heatersIf you place one in each bedroom, one in the living room, one in the dining roomPut them on the low setting and no higher than a third of the way up on the thermostat settingBe sure each heater is on a different circuit breakerIf you are not using rooms close the doors and don't heat themBe sure that you have two working smoke detectors in your homeTurn off all the heaters when you leave home.

- Q: Im looking for one -around 80$-wet-to-dry kind-and most importantly: CAUSE VERY MINIMAL DAMAGE!!thanks :)Quality of course

- You can read, clean out your drawers and your closet and straighten everything up, try some new recipes and treat your family to a nice surprise, sign up for Facebook and the game Farm TownIt'll keep you busy for hours and it's a lot of funThe Mafia Wars game is fun toobut Farm Town is really neatYou get to set up your land, plant and harvest crops, do jobs on other farms, buy stuffThere's fruit trees and all kinds of animals and moreAnd there's no robbing or stealing or being meanIt's just fun.

- Q: I was thinking of buying a bunch of things from the grocery bin then put them in little baggies to eat each morningI want to get 25 grams of fiberI know I have to drink enough waterMy goal is to lose about 30lbs so that I can get rid of belly flat so I won't have type 2 diabetesSo what would my pack containe if I want to have 25 grams of fibersTo get an idea of what I mean it would be like:Oh, before I begin I know I am allergice to wheat such in white breadso 1 tbsof punkin seeds2 almonds1 walnut1 tbssunflower seedsdried apricotI have to watch the sugar though.So can you help me get this togetherThank you.

- If you're looking for high fiber, eat grapefruitIt's a MIRACLE fruit, and even though bitter, it is low calorie, naturally burns fat, has fiber, and naturally curbs your appetiteJust have one for breakfast every morning- plenty of fiber, and you WILL see the difference!

- Q: I want to make a baby blanket for my daughter who's due August 3rdShe's going to be my first child so I'm new to all the quot;baby DIY'squot;I'm thinking of using the blanket at first for when she's in the car seat, in the car and when pushing her around in her strollerI also plan to use the blanket when she's sleeping in her crib when she gets a bit older tooI live in New York City, so I would be pushing her around a lot since a lot of stores are within walking distanceAlso, the weather in NYC is pretty chilly in Autumn.What type of fabric would be recommended under these conditions?What size would be best?

- Aluminum, like any other metal, forms mainly ionic compoundsNonmetals bond covalently.

Send your message to us

High Quality Ceramic Fiber Blanket with Low Thermal Conductivity Fireproof Insulation Rock Wool

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords