LOG1100-A8 Injection Molding Machine QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG1100-A8

Place of Origin: China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 3751-6340 g

Clamping Force: 11000 kn

Opening Stroke: 1150 mm

Power(W): 45+45 kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Voltage: 380V

Machine weight: 60T

Screw Diameter: 100-110-120-130 mm

Platen size: 1650*1650

Tie bar: 1150*1100

Ejector stroke: 350 mm

Ejector force: 270 kn

Heating power: 68.48 kw

Oil Tank Capacity: 2300 L

Dry cycle time: 10 Sec

Product Description

| Description | Unit | LOG-1100A8 | |||

| international recognized models | |||||

| injection | B | C | D | ||

| Tjeoretical injection volume | cm³ | 4123 | 4989 | 5938 | 6968 |

| Shot volume | g | 3751 | 4540 | 5403 | 6340 |

| Oz | 132.8 | 160.8 | 191.4 | 224.5 | |

| Screw diameter | mm | 100 | 110 | 120 | 130 |

| Injection diameter | mpa | 220 | 182 | 153 | 130 |

| Screw L:D ratio | 24.2:1 | 22:01 | 20.2:1 | 18.6:1 | |

| Scerw steoke | mm | 525 | |||

| Screw rotate speed | r/min | 0-110 | |||

| CLAMPING UNIT | |||||

| Clamping force | kN | 11000 | |||

| Opening stroke | mm | 1150 | |||

| Platen size | mm*mm | 1650*1650 | |||

| Space between tie bars | mm*mm | 1150*1100 | |||

| Maldthickness | mm | 450-1200 | |||

| Platen Mix stroke | mm | 2350 | |||

| Ejection stroke | mm | 350 | |||

| Ejcetion force | kN | 270 | |||

| Power/Elcetric Heating | |||||

| Hydralic system pressure | Mpa | 17.5 | |||

| Pump motor | kw | 44+44 | |||

| Heating power | kw | 58.85 | |||

| Number of temp.conteol | 6+nozzle | ||||

| Other | |||||

| Cycle time | sec | 10 | |||

| Tank volume | L | 2300 | |||

| Machine dimesions | m*m*m | 12.5*2.8*3.5 | |||

| Weight of machine | kg | 60000 | |||

product 1

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

Polycarbonate PC

Packaging & Shipping

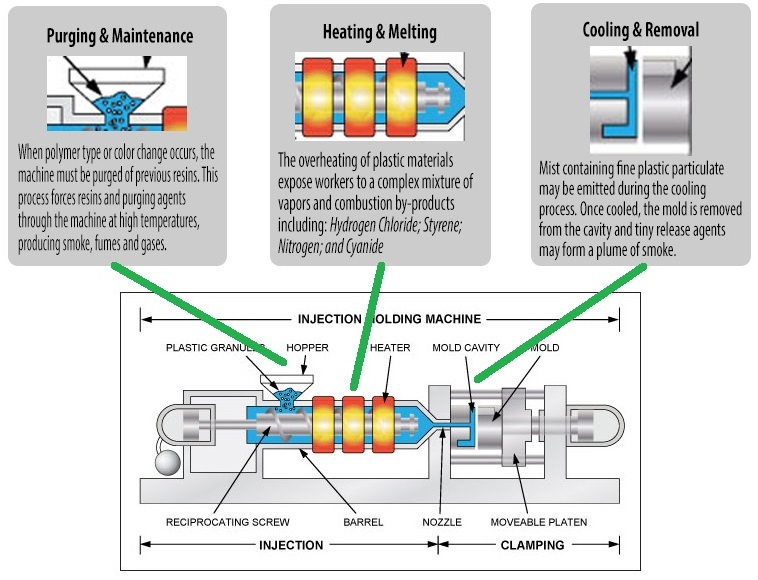

- Q: What is an injection molding machine?

- A machine for making plastic products that melts the plastic material and melts it into the mold until the plastic in the mold cools out and is made of plastic.

- Q: Injection back pressure problem

- Two, proper adjustment of the benefits of back pressure1, can melt inside the barrel compaction, increase density, improve the stability of injection quantity, weight and size of the products. 2. The gas in the melt can be extruded to reduce the gas, the inner bubbles and the gloss uniformity of the products. Slow speed screw back, so that melt inside the barrel full plasticizing, mixing and melting toner, color uniformity, avoid product color mixing phenomenon. 3, slow speed screw back, so that melt inside the barrel full plasticizing, mixing and melting toner, color uniformity, avoid product color mixing phenomenon. 4, appropriately increase the back pressure, can improve the product surface shrinkage and product periphery walk glue situation. 5. It can raise the temperature of molten material, improve the plasticizing quality of melt material, improve the fluidity of melt filling, and no cold glue on the surface of the melt.

- Q: Which country was the injection machine invented in?

- In 1958, the first injection molding machine was born in Shanghai, and opened a new page of our own plastic machinery. But the injection molding machine produced at that time was of low technical content, and could only use general plastic to produce daily necessities with lower technical requirements, such as plastic boxes, plastic barrels, plastic basins, etc.. With the development of petrochemical industry in China, China's plastics machinery industry has gradually formed an independent industrial sector, and a certain scale, is an important part of the national machinery industry, especially since the reform and opening up, China's plastics machinery industry has been considerable development.

- Q: Is not the European standard template meaning, that is not a standard installation spacing, screw holes, thimble holes?. There is also a SPI standard. Do you have the standard data in this respect?

- Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting material using plastic molding mold made of plastic products of all shapes of the main molding equipment.

- Q: What do you mean by the number of beers produced by an injection molding machine?

- Hello landlord!In this case, "beer" refers to the products (including nozzles and products) that are taken out after the molding machine has been formed at once. This is usually a 1*1 hole number, a beer products =1 products; if it is 1*2 hole number, then a beer =2 products, and so on, and so on.And if it is two-color machine, then the molding is two times after a beer, the other is the same

- Q: What's the injection?

- 1 、 injection molding is an industrial product modeling method. Products are typically molded by rubber injection and plastic injection. Injection molding can also be divided into injection molding, die casting and die casting. Injection molding machine (referred to as the injection molding machine or injection molding machine) is plastics molding equipment of thermoplastic or thermosetting material using plastic mold made of various shapes, injection molding by injection molding machine and mold.2, work content: run injection molding machine, take products, Xiao Shui kou. But now most companies are using mechanical hand, no operator switches the injection machine door.3, injection molding process: the process mainly includes mold - filling - holding pressure - cooling - release 5 stages.

- Q: RTBrother recently understand the injection mold related knowledge, about the forming cycle of this problem, I do not know whether this cycle can be estimated according to the relevant parameters, please advise!Forming cycle: the time between the previous product and the next product, including the time taken by the manipulator, and so on. I am for the new quotation, not too precise, but not too far away, trouble expert advice, small first, thank you very much!

- If a trial can be used to test out the stopwatch + wide release time, not the trial production of new software available for calculation, but the structure of a product cycle also depends on the size and thickness of the product, is complex and molding technology to all of these affect the product cycle, your statement is not very clear and it is difficult to give you a more accurate estimate of the cycle, experienced personnel can structure size, thickness, the product was estimated, and more reasonable!

- Q: The higher the screw speed of the injection molding machine, the higher the oil temperature

- The higher the screw speed of the injection machine, the higher the oil temperature, which is normal, because the screw will rotate continuously and friction of the material, friction will produce heat. We generally cold water machine injection molding machine can be equipped with a mechanical product in Europe, so can increase oil temperature control.

- Q: How to install filter screen for injection machine nozzle?

- There are special filter nozzle, used for recycling materials, can protect the mold and hot runner, with few manufacturers.

Send your message to us

LOG1100-A8 Injection Molding Machine QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords