JCM924C Hydraulic Crawler Excavator, 24.1 tons, 1.2m3 bucket

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 90 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

JCM924C Excavator's Operating Weight is 24.1t, equipped with CUMMINS B5.9-C Engine, with Boom 5.85m, Arm 3.045m, and Bucket 1.2m3.

This model use Liebherr's technology and equips KAWASAKI main pump and main valve.

JCM924C HydraulicCrawler Excavator

TechnicalSpecifications

Engine | Travel System | ||||||||||||

Model | CUMMINS B5.9-C | Travel motors | DOOSAN/NABTESCO; Variable axial piston motor | ||||||||||

Type | 6 cylinders; turbocharged; direct injection, water cooled | Travel brakes | Hydraulic oil released | ||||||||||

No. of cylinder | 6 | Travel shoes | 2×51 | ||||||||||

Bore and stroke | 102mm×120mm | Travel speed | 3.2/4.9km/h | ||||||||||

Displacement | 5.9L | Drawbar pulling force | 191kN | ||||||||||

Power output | 133kW/2000rpm | Grade ability | 70% (35°) | ||||||||||

Ground clearance | 467.5mm | ||||||||||||

Hydraulic System | Cab & Control | ||||||||||||

Pump | KAWASAKI, | Cab | All-weather, sound-suppressed Cab and equipped with a heavy, insulated Floor Mat; Front Window can be opened and slid; 6-direction adjustable Seat; LED display, Automatic monitoring, display and warning; cool & hot Air Conditioner | ||||||||||

Type | variable double–piston pump | ||||||||||||

Max. discharge flow | 2×208L/min | ||||||||||||

Max. discharge pressure | |||||||||||||

Boom, arm and bucket | 31.9MPa | Control | Two hand levers and two foot pedals for travel Two hand levers for excavating and swing; Electric rotary-type engine throttle | ||||||||||

Travel circuit | 31.9MPa | ||||||||||||

Swing circuit | 25.5MPa | ||||||||||||

Control circuit | 3.9MPa | Boom, Arm & Bucket | |||||||||||

Pilot control pump | Gear type | Boom cylinder | 130mm×90mm×1285mm | ||||||||||

Main control valve | Negative flow control | Arm cylinder | 140mm×100mm×1635mm | ||||||||||

Oil cooler | Air cooled type | Bucket cylinder | 130mm×90mm×1020mm | ||||||||||

Swing System | Refilling Capacities&lubrications | ||||||||||||

Swing motor | KAWASAKI, | Fuel tank | 360L | ||||||||||

Swing motor type | Axial-piston motor | Cooling system | 25L | ||||||||||

Parking brake | Hydraulic disc brake | Engine oil | 20L | ||||||||||

Swing speed | 10.6r/min | Travel reduction gear | 2×5.4L | ||||||||||

Swing reduction gear | 4.4L | ||||||||||||

Tail swing radius | 3086mm | Hydraulic oil tank | 250L /420L | ||||||||||

Bucket |

| ||||||||||||

Type | Backhoe bucket |

| |||||||||||

Bucket capacity | 0.9-1.2m3 (SAE) |

| |||||||||||

Bucket width | 1259mm |

| |||||||||||

Working ranges Unit: mm |

|

| |||||||||||

Arm length | 3045mm |

| |||||||||||

A | Max. digging reach | 10216mm |

| ||||||||||

B | Max. digging reach at ground level | 10029.6mm |

| ||||||||||

C | Max. digging depth | 6853mm |

| ||||||||||

D | Max. digging height | 9625mm |

| ||||||||||

E | Max. dumping height | 6823mm |

| ||||||||||

F | Max. vertical wall digging depth | 6566mm |

| ||||||||||

G | Min. swing radius | 3785mm |

| ||||||||||

H | Digging depth for 2.4m(8’)flat bottom | 6680mm |

| ||||||||||

I | Bucket capacity | 0.9-1.2m3 |

| ||||||||||

Digging Force (ISO6015) Unit: kN |

| ||||||||||||

Range | Parameters |

| |||||||||||

A | Arm length | 3045mm |

| ||||||||||

B | Bucket digging force | 129.4kN |

| ||||||||||

C | Arm crowding force | 101kN |

| ||||||||||

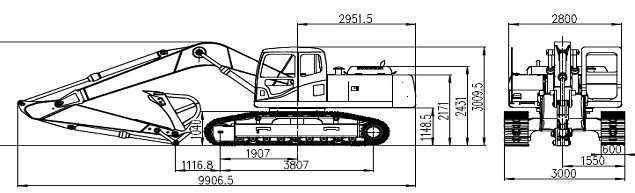

Overall Dimensions Unit: mm |

| ||||||||||||

A | Overall length | 9906.5mm | G | Tail swing radius | 3086mm |

| |||||||

B | Overall height (to top of boom) | 3255.3mm | H | Tumbler distance | 3807mm |

| |||||||

C | Overall width | 3000mm | I | Overall length of crawler | 4620mm |

| |||||||

D | Overall height (to top of cab) | 3009.5mm | J | Track gauge | 2400mm |

| |||||||

E | Ground clearance of rear end | 1148.5mm | K | Shoe width | 600mm |

| |||||||

F | Ground clearance | 467.5mm | L | Overall width of upperstructure | 2800mm |

| |||||||

|

| ||||||||||||

Operating Weight and Ground Pressure |

| ||||||||||||

Operating weight includes basic machine (with boom 5.85m, arm 3.045m, and bucket 1.2m3) |

| ||||||||||||

Shoe width | 600mm |

| |||||||||||

Overall width | 3000mm |

| |||||||||||

Ground pressure | 48.2KPa |

| |||||||||||

Operating weight | 24100kg |

| |||||||||||

- Q: Improve the excavator bucket teeth wearing resistance. Our country excavator bucket teeth service life is the main reason for the low in the following aspects: the structure design is not reasonable. Select material and heat treatment. No improper adopts the advanced surface anti-wear technology and operation and maintenance etc.

- ......ok. I'll take a guess at what you're asking. If youre wanting to know how to get longer life out of your teeth, why not just build them up with wear plate, or hard surface them? You never said what this excavator of yours is even. Big difference in what youre going to do with the baby teeth on a small excavator in the 110 and under range, versus the teeth on a 1200. if youre working in ground that will allow, you can take a length of flat cutting edge, say, from a dozer, and weld it across the face of the teeth. This gives a larger wear face, resulting in much longer life.

- Q: the health risks are from it being there

- OH.. you have septic tank problems.. Do you share a septic tank with OTHERS in the trailer park? or is it JUST your trailer and YOUR septic tank.. If it is JUST yours.. it will have to be uncovered by a PROFESSIONAL and treated.. In the future, you should use a compound that you use for septic tanks to keep them from clogging.. I suspect that you DID NOT DO THAT

- Q: a. true b. false

- a. true more capital to labor means replacing hand shovels with excavators.

- Q: How can I choose excavator bucket lip?

- There lots of different type of buckets you can choose in different tasks you needed like mud buckets, rock and other earthmoving project. If your looking bucket find Excavator Buckets Direct, you can choose many kinds of buckets at affordable cost. Cheers!

- Q: How Do I find year model for Komatsu Excavator?

- take model and serial number to a dealer or aftermarket parts dealer.maybe you could find it on the internet, but its probably easier to just have a human look up a part.

- Q: 2003 nissan almera petrol.i am an elevator installer by trade but have worked as a fitter in a hire center for the last two years.i would have a good understanding of all things mechanical and im used to stripping machines and changing parts on anything from generators to chain hoists and mini excavators.i have never worked on a car clutch however and im wondering should i leave it to a professional or have a go myself?

- No beer until the job is done! I am a DYI type myself, and have owned a lot of second hand (or more cars). From seeing the problems others have made, it is my conviction that beer and mechanical work do not mix. If you can find an engine hoist to rent (or buy) at a reasonable price, and have a second car to use for a parts runner- give some thought to doing it yourself. The sticking point on this job will come at one of two places (based on past experience)- 1. Pilot bearing. There is a special tool/s that may be needed. Some times they don't work because the old one is too far in (see the beer issue). So I have resorted to a die grinder more then once to get the old one out. Please don't do all this work with out replacing it, failure to do so can ruin the input shaft on some transmissions (see the beer issue). 2. Resurfacing the flywheel. If done soon enough the glaze will at least need to be broken for the new clutch to seat and work right. Other wise clutch chatter happens. If you have waited too long to do the job it will need resurfaced (the reason for a back up car). Of course if you get a spare fly wheel in advance (used or a light weight one) this can be avoided. Of course there will be something that goes wrong (putting the clutch disk in backwards, lost bolts, difficultly separating the assemblies or any one of other things). But if all goes close to plan, it is a four hour job. If things go wrong there might be a days delay waiting for parts. So plan accordingly.

- Q: How to distinguish between good and bad excavators, ah, there is nothing wrong with what

- The main problem is hydraulic, speak you master I am afraid you have to master, with a simple idle open action, walking and swing, do not believe the sound quality to the flat die head

- Q: I currently live in Ireland and drive a digger and I am going to Australia on a working Visa and wanted to find out how I would go about getting a ticket to drive one there

- Go to the Australian consulate in Ireland enquire there as they would know exactly how where to get an excavator ticket. Good luck, mate

- Q: Inspection and maintenanceof excavator?

- hI JACK and this expensive as it is an expensive machine to maintain due to wear.

- Q: We are working on a project up North (Nunavut, Cit anada) and there is 45,000 Gallon of JP-4 left there by the USAF in the mid-80's (probably when they turned to JP-8). That's a large volume we would preferably reused than shipped and disposed at high cost in the south. If possible, we are looking forward to mix the JP-4 with additives and use it in the heavy equipment (excavators, trucks, loaders, etc). Some info gathered on the internet mentionned to mix JP-4 with 10W30 motor oil, but we need a precise answer as we cannot afford to damage the diesel engine of the equipment. Thanks a lot for your help !

- With this much fuel, some processing is required. This could be as simple as prefiltering prior to use. In order to not harm your engines, you will need to raise the flashpoint of the JP4.(FP = 0F). Petro diesel has a flashpoint of ~180F. Mixing it with waste oil is a good idea, but proportioning will be an issue. You will need to have both the JP4 and the Oil you intend to yse tested in a local lab. You need to know the following 1. pour point 2. viscosity 3. flashpoint. then Prepare a decade series of mixtures with increasing amounts of oil 1% oil, 10% oil, 20% and so on. plot the flash points for this series and determine the exaact mixture that gives you 182 degrees F. If your JP4 is in barrels the mixing is easier. If its in a tank farm there will be more processing. You will have to deal with algae, water and a lot of sediment. good luck

Send your message to us

JCM924C Hydraulic Crawler Excavator, 24.1 tons, 1.2m3 bucket

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 90 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords