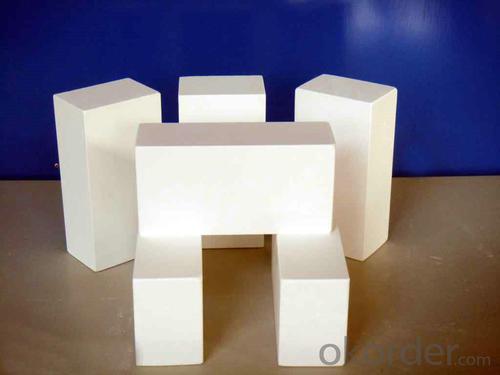

Insulating Fire Brick for Melting Furnace - Good Thermal Insulation Refractory Fire Clay Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: How do insulating fire bricks prevent heat transfer?

- Insulating fire bricks prevent heat transfer by their unique composition and structure. They are made of lightweight refractory materials that have low thermal conductivity. This means that they are poor conductors of heat, which helps to minimize the transfer of heat from one side of the brick to the other. Additionally, the bricks are designed with small air pockets or voids, which further reduces heat conduction by trapping air and preventing its movement. The combination of low thermal conductivity and trapped air pockets effectively hinders the transfer of heat, making insulating fire bricks an excellent choice for applications where heat insulation is required.

- Q: Do insulating fire bricks have a high thermal stability?

- Yes, insulating fire bricks have a high thermal stability. These bricks are designed to withstand high temperatures without deteriorating or losing their insulating properties. They are made from high-quality refractory materials that can withstand extreme temperatures, making them ideal for applications where thermal stability is crucial. Insulating fire bricks have low thermal conductivity, which means they can effectively trap heat and prevent it from escaping. This property allows them to maintain stable temperatures in environments where heat retention is essential, such as furnaces, kilns, and other high-temperature industrial processes. Overall, insulating fire bricks are known for their excellent thermal stability, making them a reliable choice for applications that require insulation and protection against high temperatures.

- Q: Do insulating fire bricks have low thermal conductivity?

- Yes, insulating fire bricks have low thermal conductivity. These bricks are specifically designed to minimize heat loss and provide excellent insulation properties. The low thermal conductivity of insulating fire bricks is due to their composition, which typically includes lightweight materials such as clay, silica, and alumina. These materials have low thermal conductivity, meaning they are not efficient at transferring heat. As a result, insulating fire bricks are highly effective at reducing heat transfer and maintaining high temperatures within a structure. This makes them ideal for applications that require insulation against high temperatures, such as in kilns, furnaces, and fireplaces.

- Q: Is it necessary to use mortar when installing insulating fire bricks?

- Yes, it is necessary to use mortar when installing insulating fire bricks. Mortar is a crucial component in the installation process as it helps to bond the bricks together, ensuring a tight and secure fit. It also helps to create a strong and durable structure that can withstand high temperatures. Without mortar, the bricks may not be properly secured and could shift or become loose, compromising the integrity of the installation. Additionally, mortar helps to fill in any gaps or spaces between the bricks, providing insulation and preventing heat loss. Therefore, using mortar is essential for a successful and effective installation of insulating fire bricks.

- Q: Can insulating fire bricks be used as a refractory lining material?

- Yes, insulating fire bricks can be used as a refractory lining material. Insulating fire bricks have excellent thermal insulation properties and can withstand high temperatures, making them suitable for applications where heat retention and energy efficiency are important. They are commonly used in furnaces, kilns, and other high-temperature industrial equipment as a lining material to prevent heat loss and protect the surrounding structures.

- Q: Can insulating fire bricks be used in gasifiers?

- Yes, insulating fire bricks can be used in gasifiers. Gasifiers are devices that convert organic or fossil fuel materials into a combustible gas called syngas. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. This makes them suitable for use in gasifiers, where temperatures can reach several hundred degrees Celsius. Insulating fire bricks help to retain heat and prevent it from escaping, improving the efficiency of the gasifier. They also offer good resistance to thermal shock, which is important in gasifier applications where rapid temperature changes can occur. Overall, insulating fire bricks are a reliable and effective choice for use in gasifiers.

- Q: How do insulating fire bricks affect the overall carbon footprint of a structure?

- Insulating fire bricks can significantly reduce the carbon footprint of a structure. These bricks have higher thermal insulation properties compared to traditional bricks, which means they can better retain heat and reduce the need for excessive heating or cooling. By improving energy efficiency and reducing the consumption of fossil fuels, insulating fire bricks help to lower the carbon emissions associated with the structure's operation. Additionally, their longer lifespan and recyclability contribute to further environmental benefits by reducing waste generation and the need for frequent replacements, ultimately minimizing the overall carbon footprint of the structure.

- Q: The difference between ordinary and diatomite brick refractory brick

- Insulation products made from diatomaceous brick and porous diatomite. The main raw material is natural porous diatomite, and then a small amount of clay and fuel are added. The volume density of diatomite brick was 0.7g/cm3, compressive strength at room temperature is 1 ~ 2MPa, the coefficient of thermal conductivity at 400 C for 0.13 ~ 0.20W/ (M - K), the apparent porosity is greater than 70%, the coefficient of thermal expansion (1280 degrees) 0.9 x 10 - 6 DEG -1, refractoriness is greater than 1250 DEG C. Mainly used in industrial kilns and other thermal equipment, thermal pipes insulation materials, generally withstand the hot surface temperature of about 1000 degrees celsius. Mainly used in industrial kilns and other thermal equipment, thermal pipes insulation materials, generally withstand the hot surface temperature of about 1000 degrees celsius.

- Q: Can insulating fire bricks be used in the construction of lime calciners?

- Yes, insulating fire bricks can be used in the construction of lime calciners. Lime calciners require high temperatures to produce lime, and insulating fire bricks are designed to withstand and retain heat. These bricks have low thermal conductivity, allowing them to effectively insulate the calciner and prevent heat loss. Additionally, insulating fire bricks are lightweight, making them easier to handle and install in the construction of lime calciners.

- Q: Are insulating fire bricks suitable for use in the construction of incinerators?

- Insulating fire bricks prove to be a suitable option for constructing incinerators. They are specifically designed to endure high temperatures and possess exceptional insulation properties. Incinerators operate at extremely high temperatures, often surpassing 1000 degrees Celsius, and require materials that can withstand such intense conditions without cracking or deteriorating. Made from lightweight refractory materials like ceramic fibers or lightweight aggregates, insulating fire bricks possess low thermal conductivity. Consequently, they effectively insulate the incinerator, preventing heat escape and maximizing energy efficiency. Moreover, the insulation properties of these bricks aid in maintaining a consistent temperature inside the incinerator, which is crucial for proper combustion and waste disposal. Furthermore, insulating fire bricks exhibit remarkable resistance to thermal shock, enabling them to withstand repeated cycles of heating and cooling without sustaining damage. This attribute is particularly vital in incinerators, where the temperature can rapidly fluctuate during the burning process. The bricks' capacity to endure thermal shock guarantees their durability and longevity in this high-temperature environment. Apart from their insulation and thermal shock resistance, insulating fire bricks offer additional advantages for incinerator construction. They possess a lightweight nature, facilitating easier handling and transportation during the construction phase. Furthermore, they can be readily cut or shaped to fit specific designs or requirements, allowing for flexibility in incinerator construction. In conclusion, insulating fire bricks stand as an ideal choice for incinerator construction due to their resistance to high temperatures, insulation properties, thermal shock resistance, durability, and ease of use. They provide a reliable and efficient solution for containing and maintaining the intense heat generated in incinerators, ensuring the safe and effective disposal of waste.

Send your message to us

Insulating Fire Brick for Melting Furnace - Good Thermal Insulation Refractory Fire Clay Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords