Insulating Fire Brick - Chamotte Refractory Insulated Fire Bricks for Fireplace

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Insulated Fire Brick

CMAX Insulated Fire Brick are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Feature of Insulated Fire Brick

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application of Insulated Fire Brick

CMAX Insulated Fire Brick can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

Image of Insulated Fire Brick

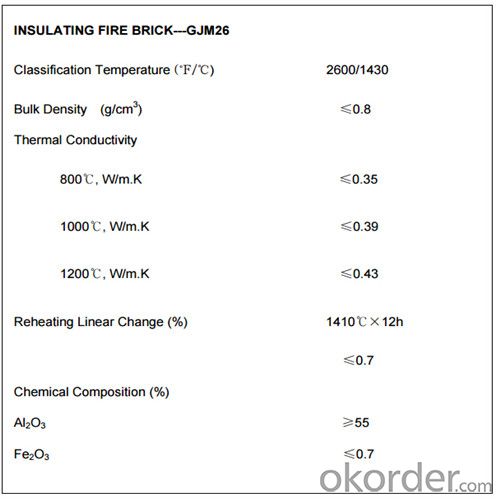

Technical Data of Insulated Firebricks

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: Can insulating fire bricks be used for insulation in walls or roofs?

- Insulating fire bricks are primarily designed for use in high-temperature applications, such as furnaces, kilns, and fireplaces. While they offer excellent thermal insulation properties, they may not be the best choice for insulation in walls or roofs of residential or commercial buildings. Insulating fire bricks are often made from lightweight refractory materials, such as ceramic fibers or expanded clay. These materials are highly resistant to heat, but they may not provide sufficient insulation against cold temperatures or moisture. Additionally, their structural integrity may not be suitable for load-bearing applications or other requirements specific to walls or roofs. For insulation in walls or roofs, it is generally recommended to use materials specifically designed for building insulation purposes, such as fiberglass batts, spray foam insulation, or rigid foam boards. These materials are better suited to provide both thermal and moisture resistance, as well as meet the necessary structural requirements. In summary, while insulating fire bricks may offer excellent thermal insulation properties, they are not typically recommended for use in walls or roofs. It is advisable to consult with a building professional or insulation specialist to determine the most suitable insulation materials for your specific needs.

- Q: Can insulating fire bricks be used for outdoor applications?

- When considering outdoor applications, it is crucial to take into account the limitations and appropriateness of insulating fire bricks. These bricks are specifically designed to offer exceptional thermal insulation, making them perfect for situations where heat retention is essential. Commonly utilized in high-temperature settings like kilns, furnaces, and fireplaces. However, when employing insulating fire bricks outdoors, certain factors must be considered. Firstly, these bricks are not as durable or weather-resistant as regular bricks. They are more vulnerable to damage caused by moisture, freezing temperatures, and exposure to the elements. Consequently, they may not be the most suitable choice for applications that necessitate long-term durability or frequent exposure to rain, snow, or extreme weather conditions. Furthermore, insulating fire bricks possess lower compressive strength in comparison to regular bricks. This indicates that they may not be appropriate for structural applications that demand a high load-bearing capacity. They are better suited for non-load-bearing purposes, such as insulation, lining, or cladding. In conclusion, while insulating fire bricks can be employed for outdoor applications, it is vital to meticulously assess their limitations and utilize them appropriately. Seeking advice from experts or suppliers is recommended to ascertain the suitability of insulating fire bricks for specific outdoor projects.

- Q: Are insulating fire bricks easy to cut or shape?

- Yes, insulating fire bricks are relatively easy to cut or shape. They can be cut using basic tools such as a saw or a knife, and they can also be shaped by using a chisel or sandpaper. Their soft and lightweight composition allows for easier manipulation and customization to fit specific requirements.

- Q: Can insulating fire bricks be used as a lining for chimneys?

- Yes, insulating fire bricks can be used as a lining for chimneys. These bricks are designed to withstand high temperatures and provide insulation, making them suitable for lining chimneys and protecting them from heat damage.

- Q: Can insulating fire bricks be used in the construction of pottery molds?

- Insulating fire bricks are indeed applicable for the construction of pottery molds. Crafted from lightweight refractory materials, these bricks possess exceptional heat insulation qualities. Specifically engineered for high-temperature applications like pottery kilns, they offer a range of benefits. When constructing pottery molds, it is imperative to utilize materials that can endure the kiln's intense heat. Insulating fire bricks can withstand temperatures of up to 3000°F (1650°C), rendering them ideal for pottery mold construction. They provide insulation to prevent heat dissipation and maintain consistent temperatures within the kiln, crucial for achieving the desired firing results. Moreover, insulating fire bricks can be conveniently shaped and cut to suit the designated mold design. Their lightweight nature also simplifies handling during the mold construction process. Additionally, the insulating properties of these bricks curtail energy consumption by preventing excessive heat loss, making them a cost-effective choice in the long term. All in all, insulating fire bricks prove to be a fitting option for constructing pottery molds due to their capacity to withstand high temperatures, offer insulation, and be easily molded to meet specific design requirements.

- Q: Are insulating fire bricks suitable for insulation in petrochemical plants?

- Insulating fire bricks, which are composed of lightweight materials with exceptional insulating properties like ceramic fibers or lightweight refractory aggregates, are well-suited for insulation in petrochemical plants. These bricks possess a low thermal conductivity that effectively curbs heat transfer and provides insulation in high-temperature settings. In petrochemical plants, where the manipulation of flammable and hazardous substances occurs, maintaining proper insulation is of utmost importance for safety and efficiency. By withstanding extreme temperatures and delivering superb thermal insulation, insulating fire bricks effectively curtail heat loss and diminish energy consumption. Moreover, insulating fire bricks exhibit resistance to chemical corrosion, rendering them suitable for deployment in petrochemical plants frequently exposed to corrosive chemicals. Additionally, these bricks demonstrate durability and commendable mechanical strength, enabling them to endure the harsh conditions typically encountered in petrochemical plants. All in all, insulating fire bricks emerge as the ideal choice for insulation in petrochemical plants due to their capacity to withstand high temperatures, exceptional thermal insulation properties, resistance to chemical corrosion, and remarkable durability.

- Q: Can insulating fire bricks be used in chimney construction?

- Yes, insulating fire bricks can be used in chimney construction. Insulating fire bricks are designed to have low thermal conductivity, which means they are effective in reducing heat transfer. This makes them suitable for chimney construction as they can help to keep the chimney walls cooler and prevent excessive heat from transferring to the surrounding structures. Additionally, insulating fire bricks are lightweight and have good insulation properties, making them easier to handle and install in chimney construction. However, it is important to note that insulating fire bricks should be used in conjunction with other fire-resistant materials in order to meet safety regulations and ensure proper chimney construction.

- Q: Do insulating fire bricks have a high compressive strength?

- Insulating fire bricks are known for their high compressive strength. These bricks are crafted from unique refractory materials, specially engineered to endure extreme temperatures and mechanical strain. Consequently, they possess exceptional compressive strength, enabling them to support substantial weights without any fissures or fractures. The remarkable compressive strength of insulating fire bricks renders them perfect for situations where structural integrity is paramount, such as in furnaces, kilns, and various industrial equipment operating at high temperatures.

- Q: Can insulating fire bricks be used for fireplace lining?

- Indeed, fireplace lining can be achieved using insulating fire bricks. These bricks are specially engineered to endure high temperatures and offer exceptional insulation. With their low thermal conductivity, they excel at retaining heat and preventing excessive heat loss from the fireplace. Consequently, they are an ideal choice for lining fireplaces as they augment the efficiency and efficacy of the heating system. Moreover, insulating fire bricks exhibit resistance to thermal shock and can withstand rapid temperature fluctuations, a crucial attribute in fireplaces where temperatures can vary significantly. All in all, incorporating insulating fire bricks for fireplace lining can enhance the performance and energy efficiency of the fireplace while ensuring its safety and durability.

- Q: Can insulating fire bricks be cut or shaped to fit different spaces?

- Indeed, it is possible to cut or shape insulating fire bricks to suit various spaces. These bricks are crafted from lightweight materials, enabling effortless customization using ordinary tools like saws, knives, or rasps. Consequently, they can be perfectly tailored to fit fireplaces, kilns, furnaces, and other high-temperature settings. Nevertheless, it must be emphasized that caution must be exercised while cutting or shaping insulating fire bricks, as they may generate dust or debris.

Send your message to us

Insulating Fire Brick - Chamotte Refractory Insulated Fire Bricks for Fireplace

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords