Monolithic Insulating Castable for Petrochemical Industry

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

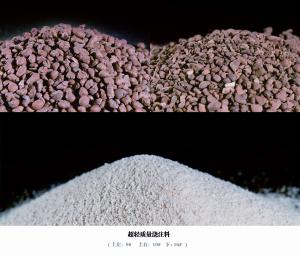

CMAX Monolithic Refractories for Petrochemical Industry including Light weight castable, Bubble alumina castable and Corundum castable. Made as per international standards, our product is known for its high strength, excellent thermal insulation and excellent thermal shock resistance. Further, these can be provided in different specifications as required by the clients.

Feature

Excellent thermal shock resistance

Excellent mechanical strength

Excellent thermal insulation

Application

Used as insulating lining materials for heating furnace, two-stage petrochemical furnace and various high temperature kilns

Used as insulating linings for many high temperature kilns

Used as linings of various high temperature kilns in petro-chemical and metallurgy industries

- Q: A brief introduction to the production process of refractory materials? What about the price of unshaped refractory production equipment and refractory refractory production line?

- Basic refractories in Magnesium Oxide and calcium oxide as the main ingredient, commonly used is brick.

- Q: Where is the development of refractory industry?

- Refractories for continuous casting is an important part of the continuous casting machine, in addition to the characteristics of general refractory material, also for the purification of molten steel and improve the steel quality, stable molten steel temperature and composition, control and regulate the flow of the molten steel and other functions, so it is called functional refractories.

- Q: Development trend of refractories

- It is necessary to promote the technological innovation of refractory materials, optimize the variety structure, optimize the industrial structure, and realize the strategy of sustainable development.

- Q: What is the construction method of ladle casting material? Where is the introduction of casting technology for unshaped refractories?

- Supply and demand imbalance, the industry must adjust the strategy, innovation has become a trend, at this point, network marketing strategy has been quietly probe.

- Q: Inorganic refractory materials industry and the glass industry than what?

- The concentration of refractory is not high, the competition is fierce and chaotic

- Q: What are the refractory materials used in metallurgical industry?

- Medium frequency furnace charge, ladle casting material, medium ladle pouring material, stainless steel high temperature heat preservation agent, dry material, magnesia, silicon dry vibration material, chromium silicon drainage agent and tundish seat brick

- Q: Will the prices in the metallurgical industry directly affect the price of refractory materials?

- In fact, this will be, but 11 Hua 11 Heng 11 in the industry is a mainstay

- Q: In industrial lining, which parts have higher requirements on the wear resistance of refractory materials

- Generally speaking, liquid has the requirements of anti erosion performance for refractory materials, such as torpedo cans (Sheng Tieshui), and the refractory materials used in his slag line have the requirements of erosion resistance and erosion resistance.

- Q: Who can help to analyze the domestic refractory market?

- China used clay less than 4000 years ago to burn pottery and to cast bronze. In the Eastern Han Dynasty (AD 25 ~ 220) have been used to make clay refractory kiln firing porcelain material and sagger. In the early twentieth Century, refractory materials were developed towards high purity, high density and ultra high temperature products. At the same time, unshaped refractory materials and high refractory fibers without firing and energy consumption were developed (for 160)Refractory materialIndustrial furnaces above 0 degrees celsius. The former, such as alumina refractory concrete, is often used in large chemical plants, ammonia synthesis plant, two - stage reformer furnace wall, the effect is good. Since 50s, the rapid development of atomic energy and space technology, the development of new energy technology, requires the use of special refractory material of high temperature resistance, corrosion resistance, thermal shock resistance, erosion has excellent properties, such as melting point above 2000 DEG C, oxide refractory compounds and high temperature composite refractory materials.

- Q: Where is the development of refractory industry?

- The rapid development of continuous casting technology of its related @ China @4 honing refractories develop and increase in variety and quality, continuous development of refractories for the continuous casting billet continuous casting production and quality have a significant impact. Especially, the completion and operation of Baosteel have greatly promoted the technological progress of refractory materials in China, and the refractory materials for continuous casting have made great progress both in variety and in quality.

Send your message to us

Monolithic Insulating Castable for Petrochemical Industry

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords