Monolithic Refractories for Petrochemical Industry - Corundum Castable

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

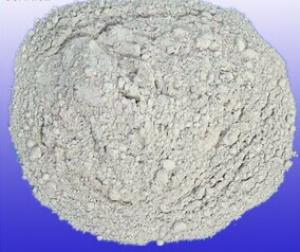

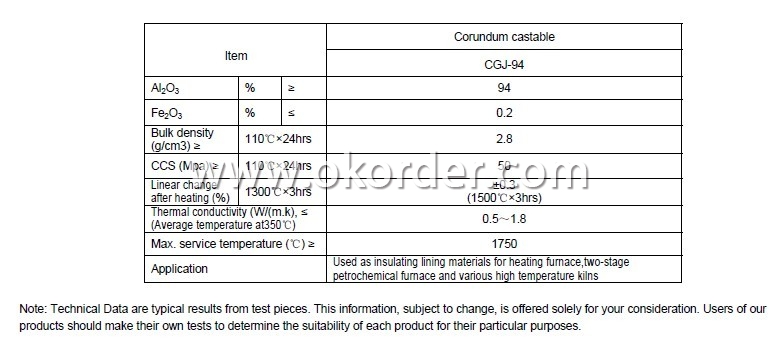

General Information of Corundum Castable for Petrochemical Industry

FIREF corundum castable for petrochemical industry which is made as per international standards, is well known for its high strength and excellent performance in the petrochemical industry. Further, it can be provided in different specifications as required by the clients.

Technical data of corundum castable for petrochemical industry

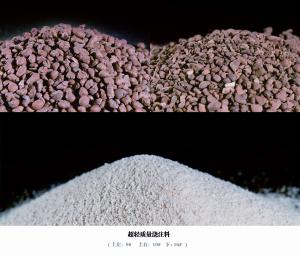

Production line and packing of corundum castable for petrochemical industry

Feature of corundum Castable for Petrochemical Industry

Excellent performance

Excellent thermal shock resistance

Excellent mechanical strength

Application of corundum Castable for Petrochemical Industry

FIREF corundum castable for petrochemical industry could be used as kiln lining materials for heating furnace, two-stage petrochemical furnace and various high temperature kilns.

Production Flow of corundum Castable for Petrochemical Industry

- Q: A brief introduction to the production process of refractory materials? What about the price of unshaped refractory production equipment and refractory refractory production line?

- Magnesium Oxide 80% to more than 85% containing magnesia brick, has good resistance to alkaline slag and slag, refractory clay brick and brick high ratio. Mainly used in open hearth furnace, oxygen converter, electric furnace, non-ferrous metal smelting equipment and high temperature equipment.

- Q: Where is the development of refractory industry?

- Continuous casting system varieties used in refractory materials include: (1) ladle refractories -- ladle lining, permanent lining, ventilation components; (2) tundish refractories -- linings and coatings, insulation board, cover; (3) functional refractories -- non oxidation casting with long nozzle, immersion nozzle, stopper, sliding gate; (4) purifying molten steel with ceramic purifier, slag dam, alkaline coating and horizontal continuous casting for separating ring gate, etc..

- Q: Development trend of refractories

- It is necessary to promote the technological innovation of refractory materials, optimize the variety structure, optimize the industrial structure, and realize the strategy of sustainable development.

- Q: What is the construction method of ladle casting material? Where is the introduction of casting technology for unshaped refractories?

- In addition, we face the serious difficulties, such as the decline in profits, the decline of high-end equipment imports and other unfavorable factors, is the most important factor in the refractory industry is facing difficulties.

- Q: Inorganic refractory materials industry and the glass industry than what?

- Glass industry is not very understanding, should be better than refractory materials, civil and real estate can be.

- Q: What are the refractory materials used in metallurgical industry?

- Thermal insulation board, joint material, covering agent, heat preservation slag agent, deoxidizer, Compound Deoxidizer and carburizing agent

- Q: Will the prices in the metallurgical industry directly affect the price of refractory materials?

- In fact, this will be, but 11 Hua 11 Heng 11 in the industry is a mainstay

- Q: In industrial lining, which parts have higher requirements on the wear resistance of refractory materials

- Generally speaking, liquid has the requirements of anti erosion performance for refractory materials, such as torpedo cans (Sheng Tieshui), and the refractory materials used in his slag line have the requirements of erosion resistance and erosion resistance.

- Q: Who can help to analyze the domestic refractory market?

- Refractories - bulk refractoryBulk refractory (unshaped refractory): unshaped refractory is a refractory material that is made up of reasonably graded granules and powders and binders and is used directly without molding and firing. Usually, the granular material called the aggregate is called aggregate and the binder is called cementing agent. This material has no fixed shape, and can be made into paste, mud, paste and loose form. Therefore, it is also known as bulk refractory. This kind of refractory can form a seamless whole structure, so it is also called integral refractory.The basic composition of unshaped refractory material is granular and powdery refractory material. In accordance with its use requirements, can be made from various materials. In order to combine these refractory materials as a whole, except for a few special cases, they are usually joined with suitable varieties and quantities of binders. In order to improve its plasticity or reduce water consumption, a small amount of proper plasticizer is added. In order to meet other special requirements, a small amount of other appropriate additives can be added.

- Q: Where is the development of refractory industry?

- The rapid development of continuous casting technology of its related @ China @4 honing refractories develop and increase in variety and quality, continuous development of refractories for the continuous casting billet continuous casting production and quality have a significant impact. Especially, the completion and operation of Baosteel have greatly promoted the technological progress of refractory materials in China, and the refractory materials for continuous casting have made great progress both in variety and in quality.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Monolithic Refractories for Petrochemical Industry - Corundum Castable

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords