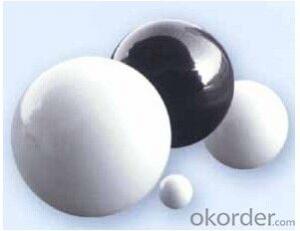

Monolithic Refractories Bearing Polishing Ceramic Ball for Petrochemical Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramica ball is the indispensable additives for metal grinding and polishing. There are various kinds of ceramic grinding balls, such as ceramics, alumina porcelain, high-frequency porcelain. The ceramic grinding balls (abrasives materials) are used at centrifugal grinders, vibratory grinders, rotating grinders, drum-type grinders, and magnetic grinders, and they can effectively de-burring .remove the oxide layer and rust on the metals.

Zirconia Ceramic Beads | |

SPECIFICATION | |

Chemical Composition: | ZrO2>94.5%, Y2O3>5.5% |

Real Density: | 6.0±0.05g/cm3 |

Bulk Density: | 3.6g/cm3 |

Hardness(Mohs): | 9 |

Whiteness: | >90 |

Sizes Available: | From 0.2mm to 30mm |

Applicable machinery: High speed stirring and ultrafine grinding, horizontal sanding machine, etc. Recommended grinding materials, high-grade paint printing ink, high-grade glaze material, magnesium hydroxide, titanium dioxide, ultrafine zirconia ultrafine zirconium silicate, ultrafine silicon powder, high purity electronic material, etc. Features:The proportion is big, high grinding efficiency, small abrasion, surface smooth as a mirror, basic no pollution for the material, also applies to some of the higher demand, higher hardness of non-metallic mineral powder grinding, but the product of grinding machinery used in cylinder liner material is qualitative hardness is higher requirements. | |

Zirconium oxide grinding medium adopts nanometer raw material. Most advanced skill in domestic & foreign

countries, with only 2ppm of self-grinding consumption.The product is used for superfine processing of power and takes crushing and dispersing

function in superfine grinding and belongs to new & high scientific & technical material grinding medium.

The balls is of high density, strong tenacity, high hardness, anti-high temperature, anti-acid, anti-alkali, anti-corrosion, anti-magnetism, anti-wearing functions, is mainly used in many fields, such as light industry, chemical, foodstuff ,medicine, superfine

crashing and grinding of high &pure materials, such as alumina, aluminum hydroxide, zirconium silicate, medicine,

foodstuff, calcium carbonate, kaoline, paint, printing ink, coating and electronic ceramic power.This kind of product

not only doesn’t pollute environment but prevents pollution of material and keeps purity of material as well.

- Q: A brief introduction to the production process of refractory materials? What about the price of unshaped refractory production equipment and refractory refractory production line?

- Basic refractories in Magnesium Oxide and calcium oxide as the main ingredient, commonly used is brick.

- Q: Where is the development of refractory industry?

- Refractories for continuous casting is an important part of the continuous casting machine, in addition to the characteristics of general refractory material, also for the purification of molten steel and improve the steel quality, stable molten steel temperature and composition, control and regulate the flow of the molten steel and other functions, so it is called functional refractories.

- Q: Development trend of refractories

- The foundation of China's refractories industry is still relatively weak, the utilization level of refractory material resources is low, the quality of refractory materials is not high, excess production capacity of ordinary products, the key products of some high-quality high technology content can be produced, but the quality is not stable, and the service life of refractory material consumption compared with foreign advanced level, there is a considerable gap.

- Q: What is the construction method of ladle casting material? Where is the introduction of casting technology for unshaped refractories?

- Now the situation is, Hua Heng refractories factory workers wages rose, financial costs are rapid growth, so the refractory products price index continues down.

- Q: Inorganic refractory materials industry and the glass industry than what?

- Glass industry is not very understanding, should be better than refractory materials, civil and real estate can be.

- Q: What are the refractory materials used in metallurgical industry?

- Thermal insulation board, joint material, covering agent, heat preservation slag agent, deoxidizer, Compound Deoxidizer and carburizing agent

- Q: Will the prices in the metallurgical industry directly affect the price of refractory materials?

- Hold the risk and adhere to the management concept of "people first and harmony together"

- Q: In industrial lining, which parts have higher requirements on the wear resistance of refractory materials

- In addition, for rotary kiln or similar kiln, refractory material at high temperature has higher abrasion resistance. In the chemical industry such as coke dry quenching device on the discharge port and corbel parts, using silicon carbide brick has good wear resistance.

- Q: Who can help to analyze the domestic refractory market?

- Refractories - bulk refractoryBulk refractory (unshaped refractory): unshaped refractory is a refractory material that is made up of reasonably graded granules and powders and binders and is used directly without molding and firing. Usually, the granular material called the aggregate is called aggregate and the binder is called cementing agent. This material has no fixed shape, and can be made into paste, mud, paste and loose form. Therefore, it is also known as bulk refractory. This kind of refractory can form a seamless whole structure, so it is also called integral refractory.The basic composition of unshaped refractory material is granular and powdery refractory material. In accordance with its use requirements, can be made from various materials. In order to combine these refractory materials as a whole, except for a few special cases, they are usually joined with suitable varieties and quantities of binders. In order to improve its plasticity or reduce water consumption, a small amount of proper plasticizer is added. In order to meet other special requirements, a small amount of other appropriate additives can be added.

- Q: Where is the development of refractory industry?

- Refractories for continuous casting is an important part of the continuous casting machine, in addition to the characteristics of general refractory material, also for the purification of molten steel and improve the steel quality, stable molten steel temperature and composition, control and regulate the flow of the molten steel and other functions, so it is called functional refractories.

Send your message to us

Monolithic Refractories Bearing Polishing Ceramic Ball for Petrochemical Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords