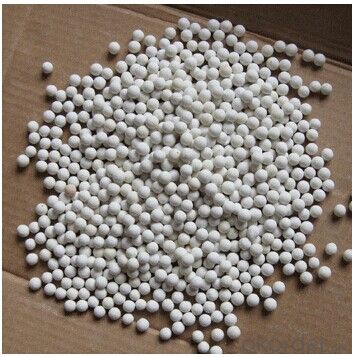

Bio Ceramic Ball Monolithic Refractories for Water Treatment in Iron and Steel Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Ingredients:

Tourmaline: 30%

Porcelain clay: 20%

High grade clay: 15-20%

Others: 30-35%

Main Features:

Amount of generating negative ions: 400500pc/s.cm3

Radiance of far infrared ray the wavelength is 225μm≥85%

PH of soaking water solution: 7.2-7.6

Insoluble, gradually releasing mineral substance

Instruction For Use:

Should wash with clean water for two times in the first, then can be directly used for treating drinking water. Keep from raining, and avoid moisture. Stored in dry place.

Note:

the highest using temperature is at 950

Description:

One kind of environmental protection and health care ball that is mainly made of the natural nonmetal mineral tourmaline, kaolin and high-grade clay by nanometer combination technology, special formula and agglomeration techniques, and used with the ceramic ball for activating, purifying and mineralizing drinking water.

Application :

For various types of water purifier, drinking water dispenser and water supply system and equipments, agriculture and industry, etc.

- Q: How do monolithic refractories contribute to the overall efficiency of ladle refining processes?

- The overall efficiency of ladle refining processes is greatly enhanced by the use of monolithic refractories. Ladle refining, a critical step in steelmaking, involves the removal of impurities and the addition of alloying elements to achieve the desired steel properties. Unshaped refractory materials, known as monolithic refractories, offer numerous benefits that contribute to the efficiency of this process. To begin with, monolithic refractories provide excellent thermal insulation. As ladle refining processes involve high temperatures, it is crucial for the refractories to withstand and contain these temperatures. Monolithic refractories have a low thermal conductivity, which minimizes heat loss from the ladle. This insulation helps maintain the desired temperature within the ladle, enabling efficient refining and reducing the energy required for heating. Furthermore, monolithic refractories exhibit high resistance to chemical attack and erosion. During ladle refining, the steel is exposed to various chemical reactions and corrosive elements. Monolithic refractories are specifically designed to withstand these harsh conditions, effectively protecting the ladle from chemical attack and erosion. This resistance ensures that the refractories maintain their structural integrity, preventing any contamination of the steel and extending the lifespan of the ladle. Additionally, monolithic refractories offer easy installation and repair. Unlike traditional brick refractories, monolithic refractories can be applied as a single, homogeneous layer, eliminating the need for complex bricklaying techniques. This ease of installation reduces downtime during ladle maintenance and repair, thus improving the overall efficiency of the refining process. Moreover, monolithic refractories can be easily patched or repaired as needed, further minimizing downtime and ensuring continuous operation. In conclusion, monolithic refractories play a significant role in enhancing the overall efficiency of ladle refining processes. Their exceptional thermal insulation properties, resistance to chemical attack and erosion, and ease of installation and repair all contribute to improving the efficiency and productivity of ladle refining. By providing a reliable and durable lining for the ladle, monolithic refractories help maintain the desired temperature, prevent contamination, and minimize downtime, ultimately resulting in improved quality and yield of the refined steel.

- Q: How do monolithic refractories perform in aluminum holding furnace applications?

- The use of monolithic refractories in aluminum holding furnace applications has been proven to be highly efficient and effective. These refractories are designed specifically to withstand the extreme temperatures and chemical environments found in these furnaces. One major advantage of monolithic refractories is their ability to create a continuous and seamless lining in the furnace. This eliminates the need for individual bricks or tiles, reducing the risk of thermal shock and cracking. The absence of joints also minimizes the likelihood of molten aluminum leaking through the lining, ensuring better containment and heat retention. Monolithic refractories also provide excellent thermal insulation properties, which are essential in aluminum holding furnaces. They have low thermal conductivity, helping to reduce heat loss and maintain a stable temperature within the furnace. This leads to improved energy efficiency and lower operating costs. Furthermore, monolithic refractories have exceptional resistance to corrosion and chemical attack from molten aluminum and its by-products, such as dross and fluxes. This resistance ensures a longer lifespan for the refractory lining, reducing the need for maintenance and downtime. In addition, monolithic refractories are known for their easy installation and repair. They can be installed quickly and easily, requiring minimal downtime for furnace maintenance. If any localized damage or wear occurs, repairs can be efficiently made by patching or spraying the affected area. In conclusion, monolithic refractories are an excellent choice for aluminum holding furnace applications due to their seamless lining, thermal insulation properties, resistance to corrosion, and easy installation and repair. These refractories significantly enhance the overall performance and efficiency of aluminum holding furnaces.

- Q: How do monolithic refractories contribute to the reduction of heat loss in iron and steel plants?

- Monolithic refractories play a crucial role in reducing heat loss in iron and steel plants due to their unique properties and application methods. These refractories are composed of single, continuous materials with no joints or seams, allowing for excellent thermal insulation and minimizing heat transfer. One way monolithic refractories contribute to heat loss reduction is through their low thermal conductivity. These materials have a high resistance to heat flow, which means they can effectively prevent the loss of thermal energy from the walls and linings of furnaces, ladles, and other equipment used in iron and steel production. By providing a barrier between the hot interior and the cooler surroundings, monolithic refractories minimize heat escape and maintain a more stable and efficient thermal environment. Additionally, monolithic refractories are known for their excellent adhesion and high strength, which enables them to form a tight seal and eliminate gaps or cracks in the lining of the equipment. This prevents the ingress of cold air or the escape of hot gases, further reducing heat loss and ensuring the desired operating temperatures are maintained. Furthermore, monolithic refractories can be easily applied and repaired, allowing for a more efficient and cost-effective maintenance process. Regular inspections and repairs can be carried out to address any wear or damage to the refractory lining, ensuring its optimal performance and minimizing heat loss over time. In summary, monolithic refractories contribute to the reduction of heat loss in iron and steel plants through their low thermal conductivity, excellent adhesion, and high strength. By effectively insulating the equipment and preventing heat escape, these refractories contribute to a more energy-efficient and productive operation in the iron and steel industry.

- Q: How do monolithic refractories withstand the alkali attacks in cement kiln applications?

- Monolithic refractories withstand alkali attacks in cement kiln applications due to their unique composition and properties. These refractories are made of high-quality materials such as silica, alumina, and magnesia, which have excellent resistance to alkali reactions. Additionally, they are designed to have dense and compact structures, limiting the penetration of alkali compounds into the refractory material. The dense structure also helps in reducing the permeability of the refractory, preventing alkali infiltration. Moreover, monolithic refractories often have a high melting point, which further enhances their resistance against alkali attacks. Overall, the combination of material composition, compact structure, and high melting point enables monolithic refractories to withstand the harsh alkali environment of cement kilns.

- Q: What are the considerations for repairing and patching monolithic refractories?

- When it comes to the repair and patching of monolithic refractories, there are several key factors that must be taken into consideration. First and foremost, it is crucial to thoroughly evaluate the extent and severity of the damage or deterioration. This assessment will help determine the most appropriate repair method and materials required. Minor cracks or small damages may only necessitate a simple patch or seal, whereas larger or more serious damage may require a complete replacement or a more extensive repair process. Secondly, the type of monolithic refractory material being utilized is a critical factor to consider. Different types of monolithic refractories possess varying properties and characteristics, such as thermal conductivity, chemical resistance, and mechanical strength. Therefore, it is vital to select a repair material that is compatible with the existing refractory material, ensuring proper bonding and optimal performance. Another factor to take into account is the operating conditions and environment in which the monolithic refractory is exposed. Variables such as temperature, pressure, chemical exposure, and abrasion can significantly impact the durability and longevity of the refractory material. Understanding these conditions will assist in selecting the appropriate repair materials and techniques that can withstand and perform well under these specific circumstances. Furthermore, it is imperative that the repair process is carried out by experienced personnel who possess knowledge about refractory materials and their installation. Improper repairs can lead to further damage or diminished performance, so it is essential to have skilled professionals who can execute the repair work correctly. Lastly, regular inspection and maintenance of the monolithic refractories are crucial in order to detect any potential damage or deterioration early on. Timely repairs and patching can prevent further deterioration and prolong the service life of the refractory material. In summary, the considerations for repairing and patching monolithic refractories involve evaluating the extent of damage, selecting compatible repair materials, understanding the operating conditions, employing skilled personnel, and conducting regular inspections and maintenance. By taking these factors into account, one can ensure effective repairs and the continued performance of monolithic refractories.

- Q: How are monolithic refractories installed and repaired in iron and steel applications?

- Monolithic refractories are installed and repaired in iron and steel applications using specific procedures to ensure optimal performance and longevity. The installation process typically involves the following steps: 1. Surface preparation: The surface where the monolithic refractory will be installed needs to be properly cleaned and prepared. This includes removing any loose material, dirt, and dust. It is crucial to have a smooth and clean substrate to ensure good adherence of the refractory material. 2. Mixing the refractory material: Monolithic refractories are typically supplied as dry powders or granules that need to be mixed with water or a specific bonding agent to form a workable consistency. The mixing process should be done according to the manufacturer's instructions to achieve the desired properties of the refractory. 3. Application: The mixed refractory material is then applied to the prepared surface using various techniques such as troweling, spraying, or casting. The choice of application method depends on the specific requirements of the installation and the type of monolithic refractory being used. 4. Curing: After the refractory material is applied, it needs to be properly cured to achieve its maximum strength and durability. Curing can be done by air drying, using heat, or a combination of both, depending on the specific refractory material being used. The curing process should be carried out gradually and according to the manufacturer's recommendations. When it comes to repairs of monolithic refractories in iron and steel applications, the following steps are generally followed: 1. Assessment: The damaged area or component needs to be thoroughly assessed to determine the extent of the damage and the appropriate repair method. 2. Removal of damaged material: The damaged monolithic refractory material is carefully removed using appropriate tools and techniques. It is important to remove all the damaged material while ensuring that the underlying substrate is not further compromised. 3. Surface preparation: Similar to the installation process, the surface where the repair will be carried out needs to be properly cleaned and prepared. Any loose material, dirt, and dust should be removed to create a clean and smooth substrate. 4. Application of repair material: The repair material, which is typically the same or similar to the original monolithic refractory, is mixed and applied to the damaged area. The application method may vary depending on the nature of the repair and the specific requirements of the refractory material. 5. Curing and post-repair inspection: The repaired area should be properly cured and inspected to ensure the quality and effectiveness of the repair. Curing and inspection procedures should adhere to the manufacturer's guidelines. In summary, the installation and repair of monolithic refractories in iron and steel applications require careful surface preparation, proper mixing and application of the refractory material, and appropriate curing procedures. Following these steps in a meticulous manner ensures reliable and durable refractory linings, which are essential for the efficient operation of iron and steel processes.

- Q: How do monolithic refractories contribute to the reduction of downtime in iron and steel plants?

- Monolithic refractories contribute to the reduction of downtime in iron and steel plants by providing superior thermal insulation and resistance to high temperatures, reducing the risk of equipment failure and unplanned shutdowns. Their ability to withstand extreme conditions, such as molten metal and slag, allows for extended operational periods without frequent maintenance or replacement. Additionally, monolithic refractories offer quick and easy installation, repair, and maintenance, minimizing the time required for downtime and ensuring a more efficient and productive operation in iron and steel plants.

- Q: How do monolithic refractories help in improving the quality of iron and steel products?

- Several ways exist in which monolithic refractories play a crucial role in enhancing the quality of iron and steel products. Firstly, these refractories are utilized for lining furnaces and other high-temperature equipment in the iron and steel industry. By offering excellent thermal insulation, monolithic refractories aid in maintaining a consistent and controlled temperature inside the furnace, thus ensuring efficient heating and melting of metals. Furthermore, the utilization of monolithic refractories aids in reducing heat loss, thereby enhancing the energy efficiency of the process. This not only leads to cost savings but also minimizes the environmental impact associated with high energy consumption. Additionally, the insulation properties of monolithic refractories contribute to the reduction of thermal stresses within the furnace, preventing cracks and other structural damages that could potentially affect the quality of the iron and steel products. Moreover, monolithic refractories possess exceptional resistance to chemical reactions, corrosion, and erosion caused by molten metals, slag, and other harsh substances. This resistance helps in maintaining the integrity of the refractory lining, preventing the contamination of iron and steel products by unwanted impurities. As a result, the quality of the final products, such as steel bars, sheets, or pipes, is enhanced, meeting the desired specifications and industry standards. Another advantage offered by monolithic refractories is their ability to provide a sleek and pristine lining surface. This smoothness minimizes the adherence of slag, molten metal, and other by-products, thereby reducing the risk of defects and ensuring a higher-quality finish for the iron and steel products. Additionally, the clean lining surface facilitates easy maintenance and cleaning, enabling efficient and effective operations. In conclusion, monolithic refractories significantly contribute to the improvement of iron and steel product quality through their exceptional thermal insulation, resistance to chemical reactions, erosion, and corrosion, as well as their ability to provide a sleek and pristine lining surface. By ensuring consistent temperatures, reducing heat loss, preventing structural damages, and maintaining a clean environment, monolithic refractories enhance the overall efficiency and integrity of the iron and steel production process, resulting in high-quality end products.

- Q: What are the challenges in repairing and maintaining monolithic refractories?

- One of the challenges in repairing and maintaining monolithic refractories is the difficulty in identifying and accessing damaged areas. Monolithic refractories are typically used in complex and intricate structures, making it challenging to locate and reach areas that require repair or maintenance. Another challenge is the high temperatures involved, as monolithic refractories are often exposed to extreme heat. This requires specialized expertise and equipment to ensure safe and effective repairs. Additionally, the composition and application of monolithic refractories can vary, making it essential to understand the specific type being used in order to perform accurate repairs and maintenance. Overall, the challenges lie in the complexity of the structures, the extreme temperatures, and the need for specialized knowledge and tools.

- Q: What are the key factors to consider when designing the lining system with monolithic refractories?

- To ensure optimal performance and longevity of the lining, several key factors must be taken into account when designing a system with monolithic refractories. These factors include: 1. Material selection: It is crucial to choose the appropriate monolithic refractory material, considering factors such as operating temperature, chemical environment, and mechanical stress. Different materials have varying properties and performance characteristics, so selecting the most suitable one for the specific application is essential. 2. Thermal expansion: Like any other material, monolithic refractories expand and contract with temperature changes. Therefore, it is important to consider the thermal expansion properties and how they will interact with the surrounding structure. To prevent cracking or spalling, proper expansion joints or design features should be incorporated. 3. Installation technique: The method of installation plays a critical role in the lining system's performance. Following the manufacturer's guidelines for mixing, placing, and curing the refractory material is essential. Improper installation can compromise lining integrity, thermal conductivity, and structural stability. 4. Bonding and anchoring: To ensure effective lining performance, a strong bond between the monolithic refractory and the substrate is necessary. Proper surface preparation, suitable bonding agents, and appropriate anchoring techniques should be considered to enhance adhesion and stability. 5. Structural design: The structural design of the lining system should be carefully planned to withstand mechanical stresses and operational conditions. Load-bearing capacity, thermal shock resistance, and thermal cycling must be taken into consideration during the design phase. Reinforcement materials, such as steel fibers or mesh, may be required to enhance structural integrity and prevent cracking or spalling. 6. Maintenance and repair: Anticipating the need for maintenance and repair is crucial for the lining system's longevity. Access points, inspection ports, and repair techniques should be considered. Regular inspections and proactive maintenance can help identify and address issues before they escalate and cause major failures. By considering these key factors, a well-designed and effective lining system with monolithic refractories can be ensured, capable of withstanding harsh conditions and providing long-term performance.

Send your message to us

Bio Ceramic Ball Monolithic Refractories for Water Treatment in Iron and Steel Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords